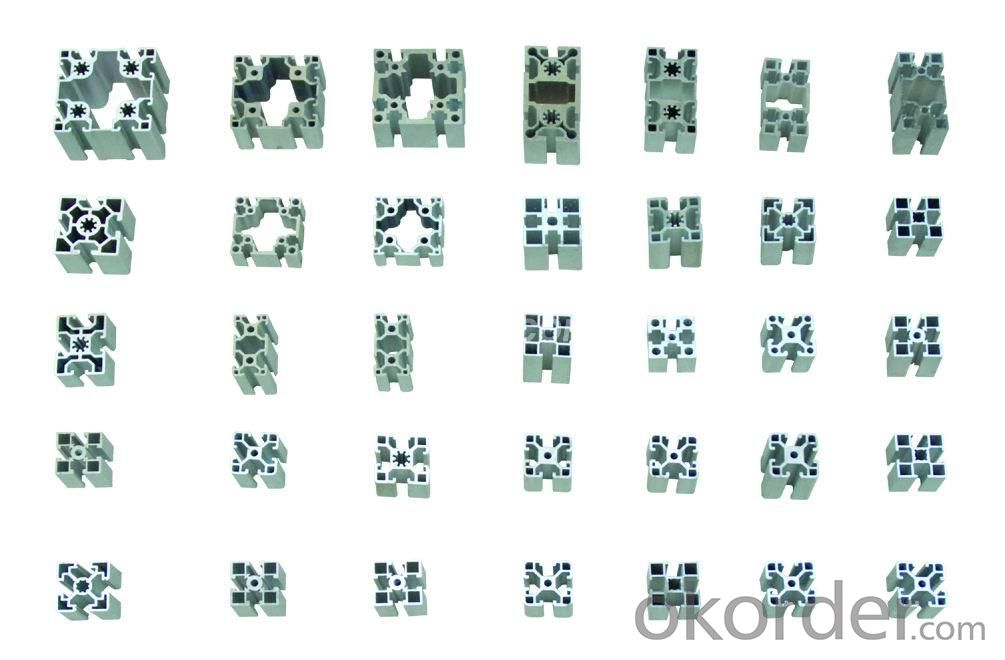

Aluminium Extrusion Profiles

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Aluminium is a relatively soft, durable, lightweight,ductile and malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible light and an excellent reflector(as much as 98%) of medium and far infrared radiation. The yield strengthof pure aluminium is 7–11 MPa, while aluminium alloys have yield strengthsranging from 200 MPa to 600 MPa. Aluminium has about one-third the density and stiffness of steel.It is easily machined, cast, drawnand extruded.

Advantage:

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Well packaged

• No marks, no scratch, no excessive oil

Alu Profile:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C at sight

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Guangzhou/Shenzhen port

4. Delivery time?

15-20 days after client’s deposit

- Q:I want to make my aluminum oxide, how much money is needed is a set of equipment? Please leave, thank you!

- Aluminum oxide brand and aluminum panel process and process, please

- Q:Can aluminum profiles be customized according to specific requirements?

- Indeed, specific requirements can be accommodated through the customization of aluminum profiles. This adaptable material can be effortlessly manipulated, trimmed, and formed to adhere to diverse design specifications. The dimensions, shape, thickness, and surface finish of aluminum profiles can all be personalized. Furthermore, drilling, bending, welding, and powder coating are additional processes that can be employed to further tailor aluminum profiles, achieving desired functionality and aesthetic allure. Such customizability renders aluminum profiles fitting for an extensive array of applications across industries, including construction, automotive, aerospace, and electronics.

- Q:Can aluminum profiles be used for lighting fixtures or systems?

- Yes, aluminum profiles can be used for lighting fixtures or systems. Aluminum is a lightweight and durable material that is commonly used in the construction of lighting fixtures due to its excellent thermal conductivity and corrosion resistance. Aluminum profiles can be easily shaped and customized to meet the specific design requirements of lighting systems, making them a popular choice in the industry.

- Q:What are the different types of fasteners used for aluminum profiles?

- Some of the different types of fasteners used for aluminum profiles include screws, bolts, nuts, rivets, and T-slot nuts. These fasteners are designed to securely join aluminum profiles together for various applications in industries such as construction, manufacturing, and automotive.

- Q:What are the different bending radius options for aluminum profiles?

- The bending radius options of aluminum profiles differ based on the particular design, thickness, alloy, and temper of the profile. Typically, aluminum profiles can be bent to a radius ranging from 1.5 to 2 times the thickness of the profile. However, this can be influenced by factors such as the strength of the alloy, the shape of the profile's cross-section, and whether it has internal or external radii. Thicker profiles generally require a larger minimum bending radius, whereas thinner profiles can achieve smaller bending radii. It is important to note that attempting to bend a profile below its recommended minimum bending radius can result in deformation, cracking, or even failure. In certain cases, aluminum profiles can undergo cold bending, which involves bending them without the need for heating. Cold bending allows for tighter radii and can be accomplished using specialized bending equipment or processes. Nevertheless, it is crucial to refer to the manufacturer's specifications or seek professional advice to determine the appropriate bending radius options for specific aluminum profiles.

- Q:Can aluminum profiles be used in the production of food processing equipment?

- Aluminum profiles are indeed applicable in the production of food processing equipment. They possess a number of advantages for this purpose due to their lightweight and versatile nature. Their non-toxic and non-corrosive properties make them an ideal option for use in food processing environments where hygiene is of utmost importance. Moreover, aluminum profiles can be effortlessly cleaned, exhibit high resistance to chemicals, and remain unaffected by moisture or humidity. In addition, aluminum serves as an efficient heat conductor, which is crucial for ensuring effective food processing. Furthermore, it boasts exceptional structural strength and can be easily fabricated to produce customized equipment. Overall, aluminum profiles are widely favored in the food processing industry owing to their enduring nature, versatility, and hygienic attributes.

- Q:How are the tonnage grades of aluminum extrusion machines classified?

- Aluminum material is soft, so it is easy to produce the top injury, pressure injury, scratch and deformation in the stamping production. Besides the requirements on the die, the following points should be done in the stamping process:1, to make aluminum stamping, reducing non-performing rate, the first to do 5S, especially clean, including mold, punch table, pipeline and packaging materials must be no sharp debris, no dirt regularly clear rectification, the upper and lower mold must be clean without debris.2, found that product burr larger, must promptly send mold maintenance, and follow the results.3, aluminum parts easier to heat, and the backlog of hard together, so in the blanking, when the material needs to be coated with a little pressure on the oil (to heat dissipation, but also smooth to clear the material), and then stamping.4, punching more products need to do blow cleaning the mold surface, do product mould, keep clean, reduce top injury, injury must be found on top of the mold top point to find out and solve the injury problems to continue production.5, push the flat mold block will produce aluminum chip, so push block production every day, must be washed under the push block aluminum scrap.Our company with advanced production equipment and technology, relying on a strong technical team, and has established a perfect quality management system, ensure the reliable quality of products, products with first-class quality, reasonable price, sold in the city and region, sales performance is good, whether we are in a peer or in the guest account, have a high reputation.

- Q:Can aluminum profiles be used for creating display systems?

- Display systems can indeed be created using aluminum profiles. Aluminum, a versatile and lightweight material, finds extensive application across various industries, including the display and signage sector. When it comes to constructing display systems, aluminum profiles offer numerous advantages. To begin with, aluminum boasts exceptional durability and resistance to corrosion, rendering it suitable for both indoor and outdoor display purposes. It can withstand diverse environmental conditions, ensuring the display system's long-lasting nature. Furthermore, aluminum profiles allow for easy customization. They can be extruded into various shapes and sizes, providing flexibility in design. This facilitates the creation of distinctive and attention-grabbing display systems that cater to specific requirements. Moreover, the assembly and disassembly of aluminum profiles are effortless, which proves advantageous for display systems that necessitate frequent adjustments or transportation. Typically, they come equipped with a straightforward slot and groove system or other connecting mechanisms, simplifying installation and maintenance. Additionally, aluminum profiles can be anodized or powder-coated to attain decorative or protective finishes. This permits customization in terms of color and texture, elevating the aesthetics of the display system. Lastly, aluminum profiles deliver structural stability while remaining lightweight. This makes them ideal for extensive displays or installations where weight becomes a concern. To summarize, aluminum profiles stand as an exceptional choice for creating display systems due to their durability, customizability, ease of assembly, and aesthetic appeal.

- Q:Can aluminum profiles be used in construction?

- Yes, aluminum profiles can be used in construction. Aluminum is a lightweight yet strong material that is resistant to corrosion, making it suitable for various construction applications. It is commonly used in the construction industry for building facades, windows, doors, roofing systems, and structural components. Additionally, aluminum profiles offer flexibility in design, easy installation, and low maintenance requirements, making them a popular choice in construction projects.

- Q:Can aluminum profiles be used in swimming pool enclosures or structures?

- Yes, aluminum profiles can be used in swimming pool enclosures or structures. Aluminum is a popular choice for constructing swimming pool enclosures due to its excellent corrosion resistance and durability. It is resistant to rust and degradation from exposure to water and chlorine, making it ideal for use in a pool environment. Additionally, aluminum profiles can be easily shaped, welded, and installed, allowing for the construction of custom-designed enclosures that meet specific requirements and aesthetics. They are also lightweight, which makes them easier to handle and transport during installation. Overall, aluminum profiles offer a reliable and long-lasting solution for swimming pool enclosures or structures.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Extrusion Profiles

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords