Aluminium Coils for Color Coated with Wall Decoration AA3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

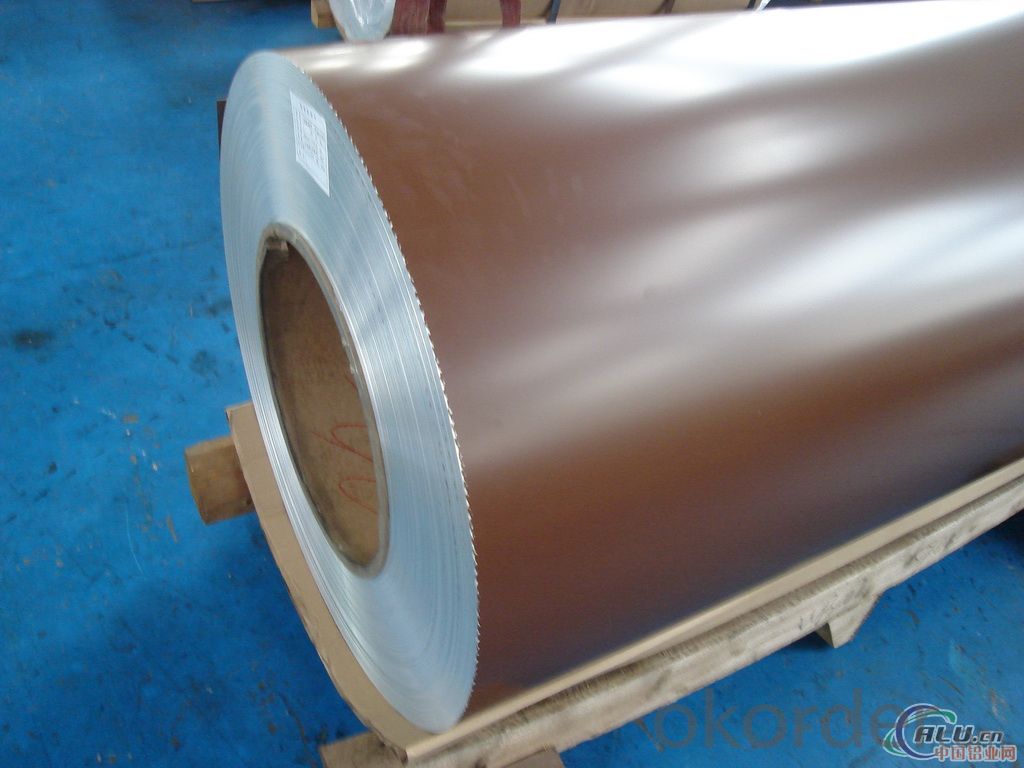

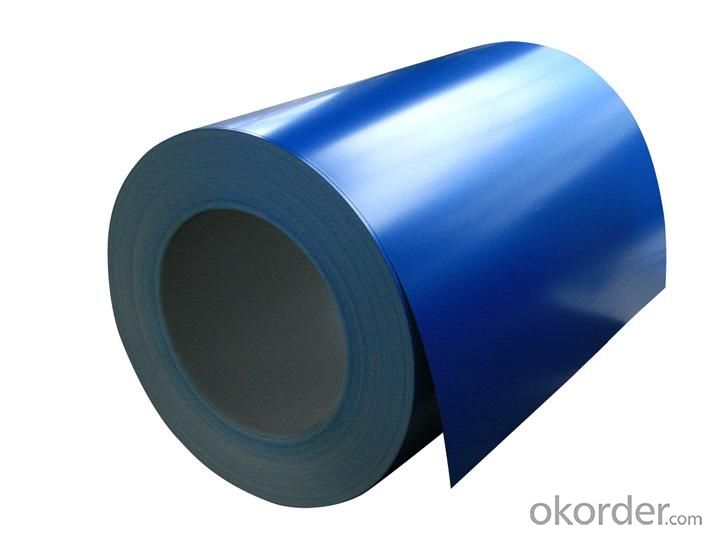

1.Structure of Aluminium Coils for Color Coated with Wall Decoration AA3003

Aluminium Coils for Color Coated with Wall Decoration AA3003 is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Aluminium Coils for Color Coated with Wall Decoration AA3003

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image of Aluminium Coils for Color Coated with Wall Decoration AA3003

4. Product Specification of Aluminium Coils for Color Coated with Wall Decoration AA3003

| Alloy | Temper | Style | Thickness | Width |

| AA1100 | H14 | Direct Casting | 0.2mm-3mm | 1000mm-1500mm |

5.FAQ of Aluminium Coils for Color Coated with Wall Decoration AA3003

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q:How do aluminum plates open holes?

- The diameter is 15 cm, a circle of great sizeIn addition can also start at the center of the circle penetrated, and set around the line, then cut along with electric jigsaw.

- Q:Are the aluminum sheets corrosion-resistant?

- Indeed, aluminum sheets exhibit resistance to corrosion. When aluminum is exposed to oxygen, a protective oxide layer naturally develops, effectively inhibiting corrosion. This oxide layer acts as a shield, separating the aluminum from its surroundings and granting the sheets exceptional resistance against corrosion. Moreover, aluminum sheets can undergo additional treatments such as coatings or anodizing processes, further amplifying their resistance to corrosion. Consequently, aluminum sheets are widely favored for applications where the necessity for corrosion resistance is paramount.

- Q:What are the different surface patterns or textures available for aluminum sheets?

- There are several different surface patterns and textures available for aluminum sheets, each designed to serve specific purposes and provide unique aesthetic appeal. Some of the most common surface patterns or textures for aluminum sheets include: 1. Smooth: Smooth aluminum sheets have a flat and polished surface without any visible patterns or textures. This type of finish is often used for applications where a clean and sleek appearance is desired, such as architectural elements or interior design. 2. Diamond Plate: Diamond plate aluminum sheets feature a raised diamond pattern on the surface, which provides excellent traction and slip resistance. This texture is commonly used for flooring, stairs, ramps, and industrial applications where grip and durability are essential. 3. Brushed: Brushed aluminum sheets have a consistent linear pattern created by brushing the surface with fine abrasive pads. This finish gives a satin-like appearance, making it popular for decorative purposes like signs, furniture, appliances, and automotive trim. 4. Stucco: Stucco textured aluminum sheets have a raised pattern resembling a stucco wall finish. This texture is achieved by embossing the sheet with a stucco roller, creating a rough and durable surface. Stucco patterned sheets are commonly used for exterior cladding, roofing, and decorative applications. 5. Hammered: Hammered aluminum sheets have a unique texture that resembles the surface of hammered metal. This finish is achieved by imprinting the sheet with a pattern of small indentations using a hammer or similar tool. Hammered sheets are often used for decorative purposes, such as backsplashes, countertops, and art installations. 6. Perforated: Perforated aluminum sheets have a pattern of small holes punched into the surface, allowing for airflow, light transmission, and sound absorption. This texture is commonly used for architectural elements, screens, filters, and ventilation systems. These are just a few examples of the surface patterns and textures available for aluminum sheets. Each texture serves a specific purpose and provides distinct visual appeal, allowing for a wide range of applications in various industries.

- Q:What does 3003-O aluminum mean?

- 3003 is a kind of AL-SI alloy of Al Mn alloyThere are four basic states of aluminum alloys:F--Free the condition of a product after a normal working procedure requires no special heat treatment or hardening, and the mechanical properties are not limited.H-- strain hardening statusO-- annealed state (the softest of all States)T-- heat treatment status

- Q:Can 101 aluminum sheets be bonded to other materials?

- Yes, 101 aluminum sheets can be bonded to other materials. Aluminum can be bonded using various methods such as adhesive bonding, welding, or mechanical fastening techniques. The choice of bonding method depends on the specific materials being bonded and the desired strength and durability of the bond.

- Q:Are aluminum sheets easy to clean?

- Yes, aluminum sheets are generally easy to clean. Aluminum is a non-porous material, which means that it does not absorb liquids or stains easily. This makes it relatively easy to wipe off dirt, dust, or spills from the surface of aluminum sheets using a damp cloth or sponge. Additionally, aluminum is resistant to rust and corrosion, so it does not require any special cleaning agents or treatments. However, it is important to note that abrasive cleaners or scrubbing pads should be avoided as they can scratch the surface of the aluminum. Overall, with regular maintenance and proper cleaning techniques, aluminum sheets can be kept clean and in good condition for a long time.

- Q:What are the dimensions of 101 aluminum sheets?

- The dimensions of 101 aluminum sheets can vary depending on the specific requirements and specifications of the sheets.

- Q:im doing a science project on aluminum and i need to know if aluminum is combustible or not. I was reading a website and they said that it reacts when its the right temperature? i really have no idea what the answer is please help! :)

- Aluminum metal oxidizes readily in air but when that happens, a layer of aluminum oxide will form, preventing further oxidation. So if you have a block of aluminum, the surface will oxidize and the rest will not. If you shave aluminum into a fine powder, you can actually light it on fire as it will rapidly and violently oxidize because there is more surface area. If you add iron powder in the mix, it will burn even hotter. I would not recommend doing this reaction.

- Q:How does the thickness tolerance of aluminum sheet affect its usability?

- The thickness tolerance of aluminum sheet plays a significant role in its usability. A narrow thickness tolerance ensures uniformity and precision in the sheet's dimensions, allowing for consistent performance and ease of fabrication. It enables seamless integration into various applications, including construction, automotive, aerospace, and manufacturing industries. On the other hand, a wider thickness tolerance can limit its usability as it may result in irregularities, difficulty in fitting, and potential performance issues. Therefore, a tight thickness tolerance is crucial for ensuring optimal functionality and versatility of aluminum sheets.

- Q:Are aluminum sheets suitable for electrical busbars?

- Electrical busbars can indeed be made from aluminum sheets. Aluminum is extensively used in the electrical industry due to its exceptional electrical conductivity, lightweight properties, and affordability in comparison to metals like copper. Aluminum sheets can be easily shaped and sized to fit the required dimensions for busbars, making them a versatile choice for electrical applications. Moreover, aluminum possesses commendable thermal conductivity, aiding in the dissipation of heat generated during electrical operations. However, it is crucial to acknowledge that aluminum has a lower electrical conductivity than copper, necessitating larger cross-sectional areas to achieve equivalent electrical performance. Consequently, it is vital to consider the specific requirements of the electrical system and seek expert advice to determine the suitability of aluminum sheets for a particular busbar application.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Coils for Color Coated with Wall Decoration AA3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords