Alloy 6082 Aluminium Extrusion Profiles For Industrial Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description

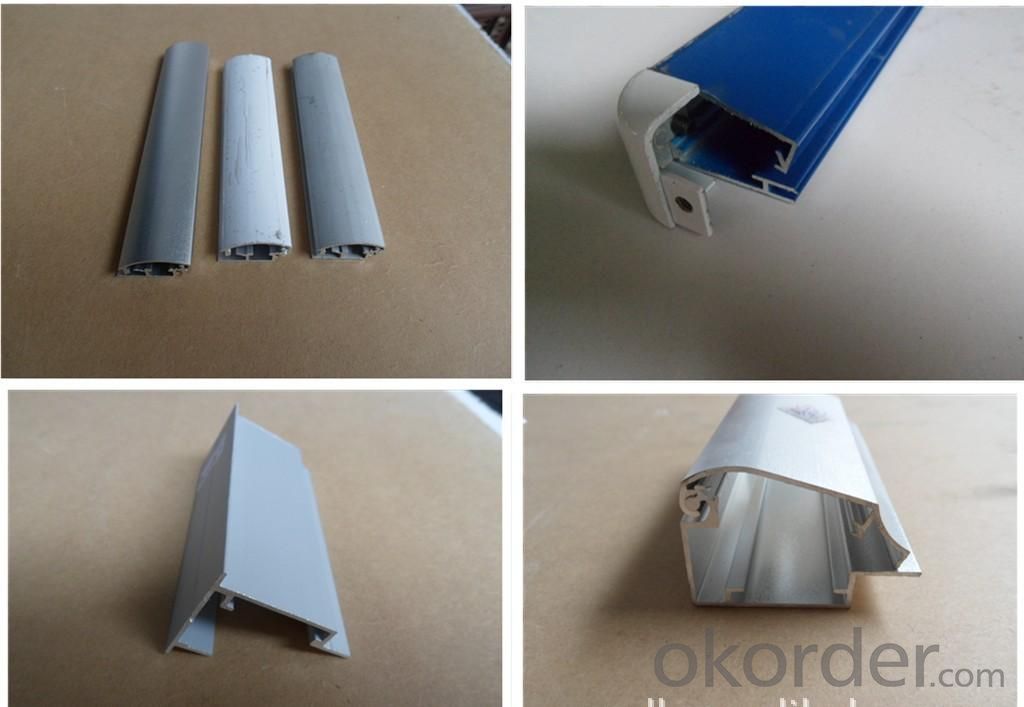

Product Name | Alloy 6082 Aluminium Extrusion Profiles For Industrial Application |

Alloy | Al 6063 T5 /T6 or 6061 T4/T6 or as customers' need |

Surface | Aluminum profiles of mill finish, powder coating, anodizing, polishing, sand blasting, electrophoresis and wood color. |

Profile shape | According to drawings or re-design as requested or market needs. |

Price | Based on Aluminum Ingot Price + Process fee |

Payment term | T/C T/T 30% deposit and 70% pay against copy of B/L |

Certificate | ISO9001 ISO14001 |

Warranty | 1. GB5237-2008 equal to EN12020-1.2(2001); 2. Within 15 years without powder peeling off; |

Product Advantages

1. Plenty of surface treatments for your choice, for example oxidation, electrophoresis and static powder coating, etc.

2. Strict control for surface finish, very little scratch.

3. Accurate mold as well as accurate size.

4. Standard alloy composition

5. Both ends of the profiles are very plain and with no burr.

FAQ

1. What is your main product?

We can supply the aluminium complete system, including aluminum billets, aluminum profile for windows and doors, aluminum for curtain wall, alumimun framwork, and kinds of aluminum windows and doors.

2. What’s your price?

The price is based on buyer's specific requirement, so please provide below information to help us quote exact price to you.

3. What is your payment term?

30% - 50% down payment, the balance payment against, and L/C is available.

- Q:Can aluminum profiles be used for display cases or cabinets?

- Certainly, display cases or cabinets can make great use of aluminum profiles. These profiles are renowned for their lightweight nature, durability, and sleek, contemporary aesthetic, making them a favored option for showcasing products or housing belongings. Their versatility is further enhanced by the ease with which they can be personalized and their availability in various sizes and shapes to meet specific design needs. Moreover, these profiles possess exceptional resistance to corrosion, rendering them suitable for both indoor and outdoor applications. Additionally, their remarkable thermal conductivity can prove advantageous in regulating temperatures within display cases or cabinets. All in all, aluminum profiles offer a diverse and appealing solution for constructing display cases or cabinets.

- Q:What are the different surface patterns available for aluminum profiles?

- There are several different surface patterns available for aluminum profiles, each offering unique aesthetic and functional benefits. Some of the most commonly used surface patterns include: 1. Smooth: This is the most basic surface pattern, with a smooth and polished finish. It provides a sleek and modern appearance, making it ideal for applications where aesthetics are important. 2. Brushed: This surface pattern is characterized by fine lines or brush strokes running in a single direction. It creates a textured and satin-like appearance, which is often chosen for its contemporary and industrial appeal. 3. Anodized: Anodizing is an electrochemical process that creates a durable and corrosion-resistant surface on aluminum profiles. It can be customized to produce various colors and finishes, such as matte, glossy, or metallic. 4. Powder-coated: Powder coating involves applying a dry powder onto the aluminum surface and then heating it to create a smooth and durable finish. This process allows for a wide range of colors and textures, including matte, glossy, and textured finishes. 5. Wood grain: By using a specialized printing process, aluminum profiles can be made to mimic the appearance of wood. This surface pattern offers the natural and warm look of wood, while providing the benefits of aluminum, such as durability and low maintenance. 6. Textured: Aluminum profiles can also be given a textured surface pattern, which can range from a fine sand-like texture to a more pronounced embossed or hammered look. Textured surfaces not only enhance the visual appeal but also provide better grip and slip resistance. These are just a few examples of the many surface patterns available for aluminum profiles. The choice of surface pattern depends on the specific application requirements, desired aesthetics, and functional needs.

- Q:How is the price of aluminum profile calculated?

- Around the Pearl River Delta area is the price of the South China Sea well-informed aluminum ingot plus processing costs accounting for aluminum prices, while the Yangtze River Delta region is the Yangtze River aluminum ingot prices plus processing costs accounting for aluminum prices. ?According to the South China Sea now well-informed aluminum ingot price 13750 plus processing fee 4000-10000, the unit price is between 17750-23750The Yangtze River aluminum ingot price is 13360, plus processing fee 4000-10000, unit price is between 17360-23360.

- Q:Can aluminum profiles be used for swimming pool covers?

- Yes, aluminum profiles can be used for swimming pool covers. Aluminum is a lightweight and durable material that is resistant to corrosion and can withstand exposure to water and various weather conditions. Aluminum profiles can be used to construct the framework of swimming pool covers, providing stability and support. They can also be used to create sliding or folding mechanisms for easy opening and closing of the covers. Additionally, aluminum profiles can be powder-coated or anodized to enhance their appearance and provide further protection against corrosion. Overall, aluminum profiles are a popular choice for swimming pool covers due to their strength, durability, and versatility.

- Q:What tests do the aluminum profiles used in the curtain wall project do?

- Accessories and fasteners for 3.2.5 and glass curtain wall shall meet the requirements of the following current national standards:"Land spring" GB / T9296"Aluminum Alloy flat open window handle" GB / T9298"Aluminium alloy window, stainless steel slide", GB / T 9300"Aluminum alloy door bolt" GB / T9297"Aluminum alloy window block" GB / T9299"Aluminum alloy door and window handle" GB / T9301"Aluminum alloy window lock" GB / T9302"Aluminum alloy door lock" GB / T9303Door closer, GB / T9305Pulley for sliding aluminium alloy doors and windows GB / T 9304Fasteners, bolts and screws, GB / T 5277"Cross slot screw" GB / T 818Mechanical properties of fasteners - Bolts, screws and studs - GBfT 3098.1Fasteners, mechanical properties, nuts, coarse thread, GB / T 3098.2Fasteners, mechanical properties, nuts, fine thread, GB / T 3098.4Fasteners, mechanical properties, bolts, tapping screws, GB / T 3098.5"Fasteners, mechanical properties, stainless steel bolts, screws and studs" GB / T 3098.6Fasteners, mechanical properties, stainless steel nuts, GB / T 3098.15

- Q:Are aluminum profiles suitable for use in medical device manufacturing?

- Yes, aluminum profiles are suitable for use in medical device manufacturing. Aluminum is a widely used material in various industries, including medical device manufacturing, due to its excellent properties. Firstly, aluminum profiles are lightweight yet strong, making them ideal for medical devices that require both durability and portability. The lightweight nature of aluminum profiles allows for easier handling and reduces the overall weight of the medical equipment, which can be beneficial for healthcare professionals and patients. Secondly, aluminum is corrosion-resistant, which is crucial in medical device manufacturing. Medical devices often come into contact with liquids, chemicals, and bodily fluids, which can lead to corrosion and degradation over time. However, aluminum profiles have excellent resistance to corrosion, ensuring the longevity and reliability of the medical devices. Additionally, aluminum profiles can be easily formed into complex shapes and designs, allowing for customization and versatility in medical device manufacturing. This flexibility in design enables the production of devices that meet specific requirements, ensuring the best possible functionality and usability for medical professionals and patients. Furthermore, aluminum is non-toxic and non-magnetic, making it suitable for medical applications where these properties are essential. Aluminum profiles do not pose any health risks or interfere with magnetic resonance imaging (MRI) or other sensitive medical procedures. In conclusion, aluminum profiles are highly suitable for use in medical device manufacturing due to their lightweight, corrosion-resistant, customizable, non-toxic, and non-magnetic properties. These factors contribute to the production of high-quality, durable, and safe medical devices that meet the demanding needs of the healthcare industry.

- Q:Are aluminum profiles resistant to chemicals or solvents?

- Yes, aluminum profiles are generally resistant to chemicals and solvents. Due to their natural oxide layer, they exhibit good corrosion resistance and can withstand exposure to many common chemicals and solvents without significant degradation or damage. However, it is important to note that the specific resistance may vary depending on the type of chemical or solvent involved, concentration, temperature, and exposure duration.

- Q:What are the different machining options for aluminum profiles?

- For aluminum profiles, there are various machining options to choose from, depending on specific requirements and desired outcomes. Some commonly used machining options for aluminum profiles include: 1. Milling: By utilizing rotating cutting tools, material can be removed from the aluminum profile, resulting in intricate shapes and features. This versatile option is suitable for both roughing and finishing tasks. 2. Drilling: Holes can be created in aluminum profiles through drilling. The precision and accuracy required determine whether a conventional drill or a CNC machine is used. 3. Tapping: To enable secure fastening, internal threads can be created in aluminum profiles through tapping. This is commonly used with screws or bolts. 4. Turning: By rotating the aluminum profile and applying a cutting tool, cylindrical shapes or features can be created through turning. This method is often employed for precise round components like shafts or pins. 5. Sawing: Aluminum profiles can be cut to specific lengths or straight cuts can be made using a saw blade. This process is known as sawing. 6. Bending: To achieve the desired form, force is applied to reshape the aluminum profile through bending. Various methods, such as press brakes or roll forming machines, can be utilized for this purpose. 7. Grinding: For a smooth, polished finish or to remove imperfections, grinding involves using abrasive particles to eliminate small amounts of material from the surface of the aluminum profile. 8. Welding: Joining aluminum profiles is commonly done through welding. This process involves melting and fusing the aluminum profiles together using heat and pressure, resulting in a strong and durable bond. These examples highlight the range of machining options available for aluminum profiles. The choice of machining method depends on factors such as the desired shape, size, finish, and specific application requirements of the profile.

- Q:What's the difference between aluminum oxide and electrophoresis?

- Main features: 1 aluminum oxide) has strong abrasion resistance, weatherability and corrosion resistance. 2) can form a variety of colors on the surface of the substrate, the maximum for your requirements. 3) hardness, making it suitable for all kinds of buildings, industrial materials.Main features: 1 electrophoresis aluminum) has strong film hardness and strong impact resistance. 2) has very high adhesion of film, aging is not easy to fall off. 3) has better wear resistance, weather resistance and alkali resistance than aluminum oxide. 4) surface color is rich, beautiful, with a mirror like luster effect.Aluminum electrophoresis processing in oxidized aluminum on the basis of better quality than the oxidized aluminum chip. The price is a little better.

- Q:How do aluminum profiles perform in terms of creep resistance?

- Aluminum profiles generally exhibit good creep resistance. Creep is the tendency of a material to deform under constant load over time. Aluminum profiles tend to have a low creep rate compared to other materials, making them suitable for applications where long-term structural stability is required. The high strength-to-weight ratio of aluminum profiles also contributes to their creep resistance, as they can withstand heavy loads without significant deformation. However, it is important to note that the creep resistance of aluminum profiles can be influenced by various factors such as alloy composition, heat treatment, and operating conditions. Proper design and engineering considerations should be taken into account to ensure optimal creep performance in specific applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Alloy 6082 Aluminium Extrusion Profiles For Industrial Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords