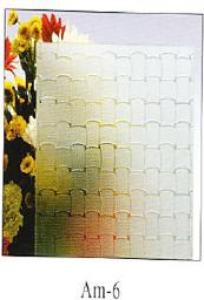

Acid Etching Glass-4

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Acid Etching Glass, which is fingerprint-proof, can be etched either a single side or both sides.

Features:

A wide range of colors and patterns:

Specifications:

Thickness: 2-12mm

Size:

3300*2440mm

300*300mm

customized size

Applications:

Acid Etching Glass is mainly used for indoor decorations like doors, windows, screens, partitions, furniture, handrails, enclosures, fences, etc.

- Q:Is it a vacuum cup with fluorine coating that affects the health?

- Fluorine is a nonmetallic chemical element, chemical symbol F, atomic number 9. Fluorine is the halogen elements of a periodic system of A VII family, located in the second period in the periodic table of elements.

- Q:Is glass a recyclable resource?

- Glass ceramic material: glass ceramics, hard texture, high mechanical strength, chemical stability and good thermal stability. But at present, the cost of traditional materials used in glass ceramics is higher. Glass ceramics made from float process and fly ash from power plants have been used to replace glass ceramics to produce glass ceramics successfully.

- Q:Medium temperature glass flake clay products

- Due to the relative stretching coefficient of the steel, cement and other material and substrate, so in the case of heat shock resin layer easily cracking and shedding, and glass flake can provide a heat stable layer, which can prevent the substrate cleavage and shedding.

- Q:Tempered and reinforced glass

- National construction technical specification for application of glass JGJ113-2003 provisions of the landing door glass must use safe glass, is from the protection of person to consider.

- Q:What's the raw material for organic glass fiber reinforced plastic? Thank you.

- Unsaturated resin, curing agent, catalyst, surface felt. There are alkali fiberglass cloth, mesh cloth, talcum powder or quartz sand. Colorant added according to product requirements. Bonus points!

- Q:Why is the process of glass toughened always broken?

- It blew the concept of rate, the national standard of our country only glass project on the wall, I do not know whether the other foreign industry to use the toughened glass also has detailed provisions.

- Q:What is the raw material for making glass?

- The 60% component of the crystal is "two oxide" (SiO2). The color of the crystal is due to the addition of two silicon oxide, which also contains a variety of trace metals. In the natural environment, and most of crystal mineral calcite, pyrite, iron ore, Hui various colors of mica, Biqian, granite, Jin Hongshi and other "symbiosis", and formed some suspected imaginary scene, the so-called "different" like crystal, crystal increased collection of fun and value.

- Q:A fireproof material is? Except glass wool, rock wool? Please tell me what is the raw material of these materials is?

- The performance of phenolic insulation board: 1, excellent fireproof performance: polyurethane and polystyrene and other organic materials, after combustion, will produce smoke and poisonous, easy to cause the deaths, but also increase the difficulty of fire suppression. The phenolic insulation board fire burning, combustion performance up to grade A, the high temperature of 180 DEG C (instantaneous 250 C), 100 mm thick phenolic foam flame resistant capacity of up to 1 hours without penetration. With carbon, no dripping, no curling, no melting phenomenon in the direct effect of flame, the flame surface to form a layer of graphite foam layer, the foam structure effective protection layer in 2, the excellent; insulation properties: low thermal conductivity (

- Q:Ceramic pots are sprayed glaze, or the whole porcelain crystallization good?

- Generally finished products are not harmful, and there is contamination in the making process. 2. glaze mainly by quartz, feldspar, kaolin and other chemical raw materials.

- Q:What is the raw material of glass made of?

- Our daily contact with most of the "flat glass is" thick to thin for doors and windows, clocks and the use of medical tests, the manufacturing method is that the furnace in the glass slurry level or traction method (also called float) and vertical traction method. After the dissolution of soluble traction after furnace also has the cooling system, cooling after the completion into a "flat glass, flat glass thickness mainly depends on the speed of traction, traction faster, can be manufactured and thinner. Although the ordinary flat glass from the front appears bright transparent, but from the side near the edge is slightly blue, because the amount of glass color depends on the main raw material in the manufacture of glass - quartz sand and iron content of purity. Generally, the thin glass used in the watch industry is superior in quality but expensive in value. The main difference is that the raw material used in the quartz sand is superior and the iron content is very low (usually under 3/10000)

We are a scientific enterprise engaged in the design, research, manufacturing, development and sale of art glass (decorative glass).

Our main products are acid etched glass, frosted glass, no fingerprint glass, deep acid etched glass, acid etched color mirror, silk screening glass, paint coated glass, color mirror etc.

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong, China |

| Year Established | 2008 |

| Annual Output Value | Above US$ 100 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Northern Europe; Southern Europe |

| Company Certifications | ISO 9001:2000;ISO 9001:2008;QS-9000;ISO 14001:2004 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Qingdao, Dalian |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | 30,000-50,000 square meters |

| No. of Production Lines | 9 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Acid Etching Glass-4

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords