6061 Aluminum Thick Plate for mold production

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Structure of Aluminum Thick Plate for mold production

The alloy 6061 has very good welding characteristics and may be welded by all of the common welding techniques. Gas tungsten arc welding is generally used for thin sections and gas metal arc welding is used for heavier sections.Commonly used in the manufacture of heavy-duty structures requiring good corrosion resistance, truck and marine components, railroad cars, furniture, tank fittings, general structural and high pressure applications, wire products, and in pipelines.

2.Main Features of Aluminum Thick Plate for for Boat and Lighting:

Good mechanical properties.

Easy processing, wearability.

Corrosion resistance

Resistance to oxidation.

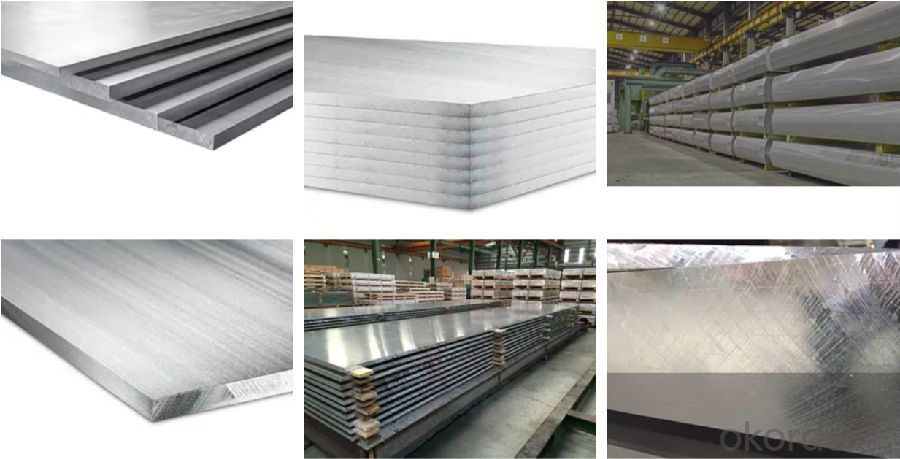

3. Aluminum Thick Plate Images:

4. Aluminum Thick Plate for for Boat and Lighting Specification:

Chemical Composition Limits for Aluminum Alloys

Composition in percent by weight according to The Aluminum Association. The values associates maximum limits unless shown as a range or a minumum.

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others Each | Others Total | Al. Min. |

| 6061 | 0.40- 0.8 | 0.7 | 0.15- 0.40 | 0.15 | 0.8- 1.2 | 0.04- 0.35 | 0.25 | 0.15 | 0.05 | 0.15 | Rem. |

| 7075 | 0.40 | 0.50 | 1.2-2.0 | 0.30 | 2.1- 2.9 | 0.18- 0.28 | 5.1- 6.1 | 0.20 | 0.05 | 0.15 | Rem. |

| 2024 | 0.50 | 0.50 | 3.8-4.9 | 0.30-0.9 | 1.2- 1.8 | 0.10 | 0.25 | 0.15 | 0.05 | 0.15 | Rem. |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchanging experience with several quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes and video,we will be responsible.

- Q:Can aluminum sheets be used for food processing conveyors?

- Yes, aluminum sheets can be used for food processing conveyors. Aluminum is a lightweight, durable, and corrosion-resistant material that is often preferred in the food industry due to its hygienic properties. It is commonly used for making conveyor belts and other equipment in food processing facilities.

- Q:Can 101 aluminum sheets be used in the production of musical instruments?

- Certainly, the utilization of 101 aluminum sheets is feasible in the manufacturing of musical instruments. Aluminum, being a lightweight and durable metal, finds wide application in the production of diverse musical instruments. Its resonating properties are commendable, ensuring the generation of a vibrant and distinct sound. Furthermore, the exceptional malleability of aluminum facilitates effortless shaping and molding into various musical instrument components like bodies, frames, or keys. Thus, the incorporation of 101 aluminum sheets unquestionably enhances the overall quality and performance of musical instruments.

- Q:Are aluminum sheets suitable for beverage cans?

- Yes, aluminum sheets are suitable for beverage cans. Aluminum is a widely used material in the beverage industry due to its unique properties. It is lightweight, corrosion-resistant, and provides an excellent barrier against light, oxygen, and moisture, which helps to preserve the quality and freshness of the beverage. Additionally, aluminum is easily formable, allowing for the production of various can shapes and sizes. It is also recyclable, making it an environmentally friendly choice. Overall, aluminum sheets are an ideal material for beverage cans, meeting both functional and sustainability requirements.

- Q:Can aluminum sheet be used for electrical wiring?

- No, aluminum sheet cannot be used for electrical wiring.

- Q:Are aluminum sheets suitable for use in cryogenic environments?

- Certainly, aluminum sheets prove to be a fitting choice for utilization in cryogenic surroundings. With its exceptional thermal conductivity and low density, aluminum emerges as an optimal substance for cryogenic purposes. It can endure exceedingly cold temperatures while maintaining its structural integrity and avoiding noticeable thermal expansion. Moreover, aluminum exhibits commendable resistance against corrosion and can be conveniently fashioned into diverse configurations and sizes. These attributes render aluminum sheets widely employed in cryogenic systems, including cryostats, superconducting magnets, and liquid nitrogen storage tanks.

- Q:What is the maximum temperature that the aluminum sheets can withstand?

- The maximum temperature that aluminum sheets can typically withstand is around 600 degrees Fahrenheit (315 degrees Celsius).

- Q:Can aluminum sheets be anodized in different finishes?

- Different finishes can be achieved when anodizing aluminum sheets. Anodizing, an electrochemical process, enhances the natural oxide layer on aluminum, increasing its thickness and durability. It is possible to customize this process to achieve clear, colored, or textured surfaces. The finish type relies on factors such as alloy composition, anodizing technique, and desired appearance. Due to their corrosion resistance, aesthetic appeal, and ability to maintain color over time, anodized aluminum sheets find extensive use in architecture, automotive, and electronics industries.

- Q:Are aluminum sheets suitable for pharmaceutical applications?

- Yes, aluminum sheets are suitable for pharmaceutical applications. They are commonly used for packaging pharmaceutical products due to their excellent barrier properties, lightweight nature, and resistance to corrosion. Aluminum sheets help to protect the contents from moisture, oxygen, and light, ensuring the stability and effectiveness of pharmaceutical drugs. Additionally, aluminum sheets can be easily formed into different shapes, making them ideal for creating blister packs, caps, and closures for pharmaceutical packaging.

- Q:Can the aluminum sheets be used for manufacturing furniture?

- Yes, aluminum sheets can certainly be used for manufacturing furniture. Aluminum is a lightweight and strong material, making it ideal for creating furniture that is both durable and easy to move around. Additionally, aluminum is resistant to corrosion, so it can withstand exposure to various environmental conditions. Moreover, aluminum sheets can be easily shaped and formed into different designs, allowing for versatility in furniture manufacturing. Overall, using aluminum sheets for furniture manufacturing can result in high-quality, stylish, and long-lasting pieces.

- Q:a 1 kg block of aluminum and a 1 kg block of lead are immersed in water, Both sink, but which experienced the greater buoyant force? Why?

- 1 kg of Aluminum will require more volume to occupy since it is lighter than lead. Lead has more density to Aluminum.So, when immersed in water Aluminum will displace more volume of water than lead. The buoyant force is equal to the Mass of water thus dispalced . Thus we can say Aluminum will experience more buoyant force.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

6061 Aluminum Thick Plate for mold production

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords