5083 Aluminium Alloy Plate for Marine/Aluminium Cast Plates 5083 5052

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

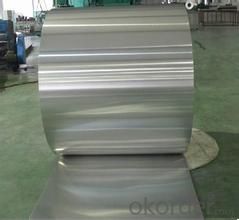

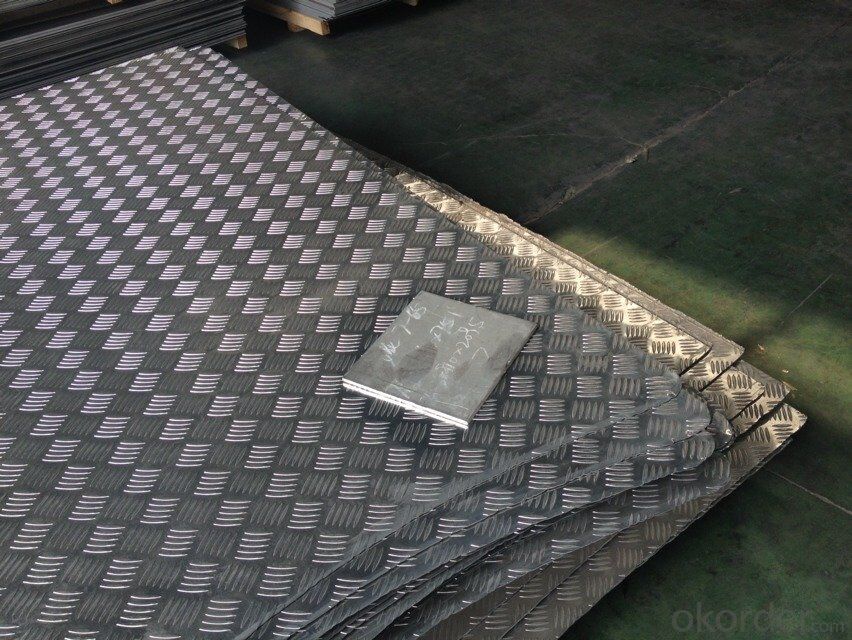

Aluminum Sheet for Making Aluminum Composite Panel

Aluminum sheet specifications:

1) Alloy : 1050 1060 1070 1100 2024 3003 3004 3105 3A21 5005 5052 5083 5754 5182 5454 5456 6061 6063 7075 8011 etc

2) Temper: O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc

3) Thickness: 0.1mm to 300mm

4) Width:20mm to 3300mm

5)Length: ≤ 12000mm

6) Protective film can be added

7) Production Line: DC and CC production line

Discription:

Width: 50-800mm

Thickness: 8-25mic

Length: 3-300m

Character:

High-temperature sterilization

Made of advanced food grade alu material,no pollution

Eco-friendly, recoverable and recyclable

Application:

widely used for food cooking, freezing wrapping, storing etc, the main application are for household and catering, which are targeting for retail market and food service market, such as hypermarket, chain store and hotel, restaurant etc.

Packing:

One roll in an individual box or printed PP bag

Certain quantities in a standard carton

Depends on customer’s request

Service

1. We have the good and professional team, have a good after-sales service.

2. Accept any drawings or your samples to develop new product.

3. Offer relateive technical support,quick response,all your inquire will replied within 24 hours.

4. OEM, buyer design, buyer label services provided.

5. Have the certification of ISO 9001, SGS.

6. Special discount and protection of sales area provided to our distributor.

FAQ

Q1:Do you provide sample? How many days will samples be finished?

Free samples will be provided if needed, but customers should undertake shipping cost or freight charges, samples will be finished in 5-7days

Q2: Can we visit your factory?

Welcome to our factory at any time.

Q3: Complaint solving process

Finding your salesman—Salesman provide you the solution (If it’s our responsibility, we will resend substitutes or return money or provide discount for your next order, etc.; If it’s shipping company’s responsibility, we will also help you until the problem is resolved.) —If salesman can’t solve your problem, please call our manager .

Q4: Delivery time

3~30working days after confirming the payment. If the order is urgent, we will push our workers to finish in advance.

Q5: What's your MOQ?

Normally 8MT are requested as the minium order quantity ,we shall give

additional instructions in special circumstances.

Q6: What are the terms of payment and currencies do you accept?

T/T or L/C is accepted, currently we appreciated your payment through

USD,EUR, RMB

Q7: Do you accept customized orders?

Yes, we do. Your customized orders are always welcomed. Please kindly offer us your samples or drawings, so that we can customize the products according to your preferences. About any further detail, please feel free to contact us.

Q8: What information should I let you know if I want to get a quotation?

Your detailed requirements regarding the products's dimensions, including shape, thickness, top out (length*width*height), and your order quantity are highly appreciated if you want further information about our quotation

Q9: How about the mass production?

The lead time of mass production depend on quantity, usually 25-30days (20FT) .

- Q:Can aluminum sheets be used for decorative or architectural purposes?

- Aluminum sheets have multiple uses in decoration and architecture. This versatile material can be easily shaped and molded into various forms, making it perfect for a wide range of architectural projects. It is commonly utilized in exterior cladding, roofing, window frames, and facades, lending a sleek and contemporary appearance to buildings. Moreover, aluminum sheets are also employed for decorative purposes like wall panels, art installations, signage, and furniture. Architects and designers often choose aluminum due to its lightweight and durable properties, enabling them to create visually appealing and functional structures. Additionally, aluminum's resistance to corrosion makes it suitable for both indoor and outdoor applications.

- Q:Remember the notorious Chevy Vega of the 1970's? As I recall,one the big problems with that car was that it was equipped with an aluminum block engine. The new Ford Mustangs arealso equipped with aluminum engines to reduce curb weightand improve fuel efficiency. Will they be prone to the sameproblems that the Vega had down the road? Are there othermanufacturers that have used aluminum engines with successrecently?

- Aluminum is a WEAK metal....it is SOFT compared to iron or CGI. It sucks in engines.

- Q:How much should I be charged to have aluminum siding installed? I have a two floor single family home which is detached. I also would want new gutters installed and soffets (i think that is what they are called). One company estimated 12k and another said 10K. This would entail just putting the siding over the original siding. Any answers are appreciated.

- They don't make aluminum siding anymore, thank god, they only make vinyl siding. It really depends on the brand you buy and the company that installs it. I used to be a tin man before becoming a professor and I can tell you that you should do a little research first. You want stuff that will hold up in wind, is easy to clean, has a nice look and colors won't fade. You want to be sure it is made of virgin vinyl, sounds weird but trust me, if it isn't it'll fade in a few years and look like crap. The company needs to know what they are doing too or the seams and lines will be terrible, so make sure your company is really in the siding business and not just some jack-leg contractor that says I can do it. You will end up with a crap job. Now I can't remember for certain and it has been a number of years, but 10 to 12 sounds good. I hope they are going to remove the old stuff, check your wood underneath and possibly put on a moisture barrier. I would ask what they plan on doing in detail. Good luck.

- Q:Can the aluminum sheets be used for manufacturing automotive wheels?

- Yes, aluminum sheets can be used for manufacturing automotive wheels. Aluminum is a lightweight and durable material that is commonly used in the automotive industry due to its high strength-to-weight ratio. Aluminum sheets can be formed and machined into the desired shape and specifications required for automotive wheels. Additionally, aluminum has excellent corrosion resistance properties, which is beneficial for automotive wheels that are exposed to various weather conditions and road debris. Overall, aluminum sheets are a suitable material for manufacturing automotive wheels, providing a balance of strength, weight, and corrosion resistance.

- Q:Are aluminum sheets suitable for electrical applications?

- Aluminum sheets are appropriate for electrical applications, as they possess numerous advantages. Primarily, aluminum is a highly conductive metal, which has led to its increasing popularity in electrical applications. Furthermore, its lightweight nature and exceptional heat dissipation properties make it an optimal choice for applications that necessitate efficient thermal management. This is particularly critical in electrical systems where heat generation occurs, including power transmission lines, electrical panels, and heat sinks. Moreover, aluminum sheets exhibit high resistance to corrosion. Unlike certain other metals, aluminum forms a protective oxide layer on its surface, preventing further oxidation and corrosion. This makes it a reliable option for electrical applications that are exposed to harsh environments or moisture. Additionally, aluminum is a cost-effective alternative compared to other metals frequently used in electrical applications, such as copper. It is easily obtainable and has a lower price point, making it appealing to both manufacturers and consumers. However, it is important to acknowledge that aluminum has lower electrical conductivity than copper. Consequently, for certain applications where high conductivity is essential, such as power transmission lines, copper may still be preferred. Nonetheless, advancements in technology and design have enabled aluminum to be effectively utilized in a wide range of electrical applications, encompassing wiring, connectors, bus bars, and transformers. In summary, aluminum sheets are indeed suitable for electrical applications, offering advantages like lightweight construction, exceptional thermal management, corrosion resistance, and cost-effectiveness. The ultimate determination of whether to employ aluminum or another material hinges on the specific requirements and limitations of the electrical application in question.

- Q:How to mix solid aluminium sheet with solid copper sheet (using heat?) to make a compound.

- I'm not sure if I correctly understand your question - that is, whether you're asking how to physically fasten copper and aluminum pieces together, or of you're asking how to make intermetallic compounds of copper and aluminum. Since you did mention a compound, though, I'm guessing the latter. Copper and aluminum do react to form a number of intermetallic compounds. Among these are Al4Cu9, AlCu, and Al2Cu (see first reference below). These are referred to as aluminides of copper, and may be prepared by melting the two metals together in the proper ratio by weight and cooling slowly. For example, Al2Cu (also called CuAl2) may be prepared by melting a mixture containing 96% aluminum and 4% copper (see second reference below). Note that a protective inert atmosphere is desirable for any work of this sort to prevent oxidation. CORRECTION: The compound CuAl2 contains about 54% copper and 46% aluminum (NOT as above). It's the 2000 series aluminum alloys which contain around 4% copper, and it is the precipitation of CuAl2 during heat treatment which makes them hardenable. The final sentence in the second paragraph above should read: For example, Al2Cu (also called CuAl2) may be prepared by melting a mixture containing 46% aluminum and 54% copper (see second reference below).

- Q:Can aluminum sheets be powder coated?

- Yes, aluminum sheets can be powder coated. Powder coating is a popular finishing process that involves applying a dry powder to a surface, such as aluminum, and then curing it through heat to create a durable and attractive finish. Aluminum is commonly powder coated due to its lightweight, corrosion-resistant, and versatile nature. The powder coating process provides excellent adhesion to aluminum sheets, resulting in a smooth, even, and long-lasting finish. It also offers a wide range of color options and can be used for various applications, including architectural, automotive, and industrial uses.

- Q:How much is a square inch of a millimeter aluminum plate?

- The weight of 2.73 kg / square meter5 Series refers to magnesium as the main alloy element, that is, aluminum magnesium alloy.

- Q:Are aluminum sheets suitable for food-grade applications?

- Indeed, food-grade applications can utilize aluminum sheets. Due to its exceptional attributes, aluminum is extensively employed in the food industry. It is known for being non-toxic, resistant to corrosion, and possessing a high level of thermal conductivity. Consequently, it proves to be a fitting option for both food processing and packaging. Not only can aluminum sheets be utilized in the creation of food-grade containers, trays, and packaging materials, but they are also commonly employed in cooking utensils. For instance, baking sheets and foil made from aluminum are safe to use when in direct contact with food. Moreover, aluminum sheets are easily cleaned and sanitized, thereby making them a hygienic choice for food-grade applications.

- Q:Can the aluminum sheets be used for manufacturing heat sinks?

- Aluminum sheets are capable of being utilized in the production of heat sinks. Owing to its exceptional thermal conductivity features, aluminum is a favored option for heat sinks. It possesses lightweight properties, exhibits high electrical conductivity, and can be easily machined, rendering it an ideal substance for dissipating heat from electronic components. The malleability of aluminum sheets permits them to be effortlessly shaped, cut, and molded into the desired heat sink design, facilitating effective heat transfer and dissipation. Furthermore, aluminum is resistant to corrosion, which guarantees the enduring and dependable performance of the heat sink. In summary, aluminum sheets are widely employed in the manufacturing of heat sinks for a variety of applications across industries such as electronics, automotive, and aerospace.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

5083 Aluminium Alloy Plate for Marine/Aluminium Cast Plates 5083 5052

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords