2015 Hot Sale popular Silicon Carbide Recycle Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

2015 Hot sale popular silicon carbide recycle refractory

Our silicon carbide is processed

based on FEPA standard

or customers' requirement

Consistent quality is our advantage

Silicon carbide

Silicon Carbide

Silicon carbide powder

Brand name JIAXING

Based on FEPA JIS standard from F24 to F1200 or JIS 60# to 4000#

for abrasive wire saw etc..

processed based on FEPA standard or customers' requirement

Consistent quality is our advantage

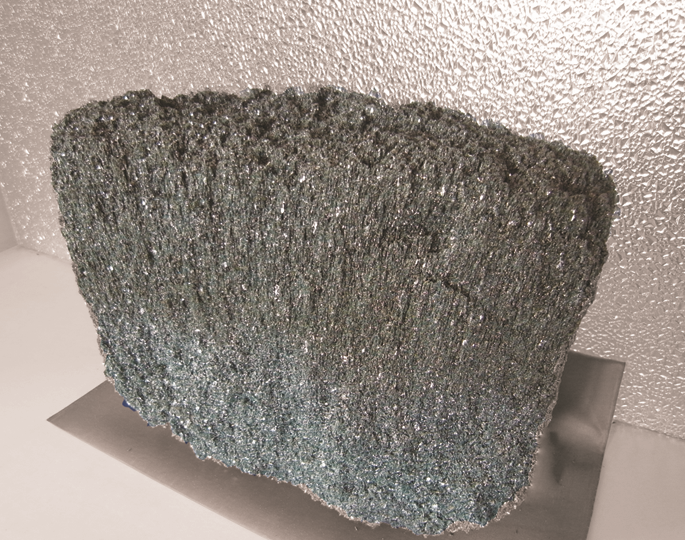

characterized by its high wear resistance and good mechanical properties Its typical characteristics are as following

Low density and high strength

Good resistance to high temperature

Good wear resistance and anti-friction properties

Excellent resistance to sudden changes in temperature

Good chemical resistance and oxidation resistance

Low thermal expansion and high thermal conductivity (superior to steel)

Good electrical conductivity

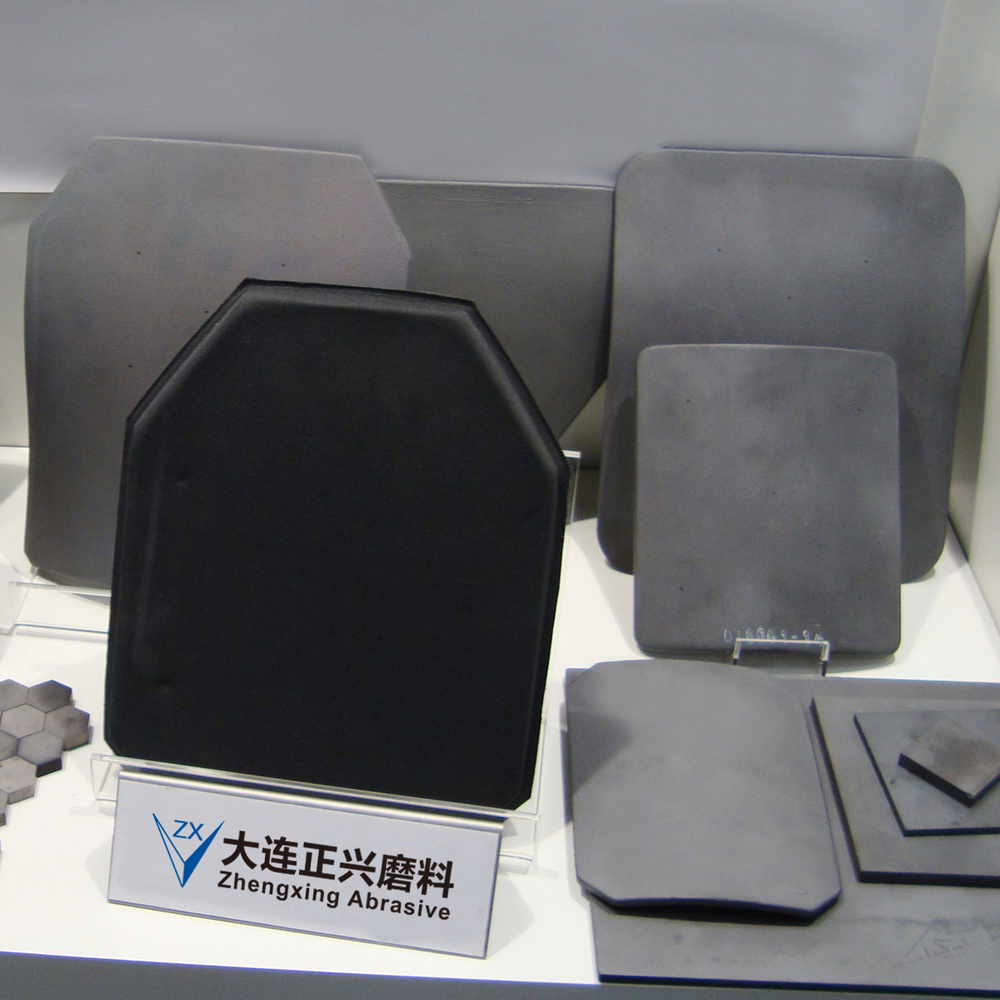

Typical Application

Fixed and moving turbine component

Seals, bearings, pump vanes, ball valve parts

To be used in refractory industry and metallurgical industry e.g. kiln furniture etc

Heat exchanger e.g. electric heat elements etc

Semiconductor water processing equipment e.g. wire saw polishing plates for semiconductor wafer

Due to its high hardness and brittle granular it is used as abrasive agent grinding wheel sandpaper etc in abrasive field and as sharpening abrasive on wood and metal

Other using lightening arresters wear components for paper-making machines special seals for chemical processing industry etc

- Q:what is steel fire door made of ?

- 1. fire resistance steel door has steel made door frames, door leaf framework and door panels. if the door leaf is filled with nontoxic fire insulation material, added with fireproof hardware accessories, which consists of a door that is fire resistance. This is a steel door.

- Q:Can anyone tell me what material the first rate fire resistant door is?

- Material of Class A fire doors can be divided into steel and wood, so fire doors can be divided into fireproof steel door and fireproof wooden door. In fact, fire doors of all classes are divided into steel, wood, steel and wood, and other materials (see GB ). Mainly depending on what kind of material the customers want. The fire door is called class A fire door not because of the material but because of the fire-resistant time. The fire resistant time of class A fire door is not less than 1.2 hours and fire doors as long as meeting this condition can be called class A fire doors . The filling material in class A fire doors is generally perlite, whose difference is in thickness. A few of them will use fireproofing materials like foam core board, vermiculite fireproof board, MC composite material and so on. The thickness of class A fire door is usually 50mm. I hope my answer can help you.

- Q:What material is refractory material?

- alumina refractory concrete, silica brick clay brick, metal ceramic, high temperature machine coating fiber reinforced ceramics, diatomite product, asbestos products, insulation board refractory. The definition of refractory can be searched in the website.

- Q:In entering fire door, which material does well?

- Now generally do stainless steel.

- Q:What are the standards of refractory concrete ?

- General requirements (1) All the materials for compounding refractory concrete must meet the design requirements and they should be checked according to the relevant standard. (2) The compounding of refractory concrete should be done strictly in accordance with the compounding proportion (usually weight), and the using of various binders, aggregates, coagulant, and water should be accurately measured. Tolerance of difference of cement, powder and water should be not more than 1 %; weight of aggregates does not exceed 3%. (3) The mix of different varieties of concrete must be prevented. (4) A variety of raw materials should be piled separately according to different species, mark numbers, dates of manufacture. Do not mix with limestone, silica, railroad ballast, dirt and other harmful debris.

- Q:What are the models of refractory cables?

- There are bout four types. 1.NA-YJV / NB-YJV Crosslinked polyethylene insulated PVC sheath A (B) class fire-resistant power cable 2.NA-YJV22 / NB-YJV22 Crosslinked polyethylene insulated steel belt braiding PVC sheath A (B) class fire-resistant power cable 3.WDNA-YJY / WDNB-YJY Crosslinked polyethylene insulated polyolefin sheath A (B) class low smoke no halogen fire retardant power cable 4.WDNA-YJY23 / WDNB-YJY23 Crosslinked polyethylene insulated steel belt braiding polyolefin sheath A (B) class low smoke no halogen fire retardant power cable

- Q:What are the new types of refractories? What are the characteristics? Their applications and developments?

- A new type of refractory materials are: A12O3-TiO2-SiO2 refractories, MgO-A12O3-TiO2 refractories, MgO-CaO-TiO2 refractories, MgO-SiC-C refractories, nanotechnology MgO-C brick, MgO-AL2O3-AIN refractories, MgO-La2O3 refractories etc..

- Q:It the Special Fire-Proof Material belonged to ceramics? Is there a national standard of the Special Fire-Proof Material?

- The fiber and reinforcing material of the metal ceramic is also belonged to the Special Fire-Proof Material. ~~~~GB is too much trouble, GB online should ~~~ Lei Bao Refractories for you. The high temperature inorganic coating. 5. The refractory compound. 3. The high melting point oxide. You can search it on the internet according to the classification~~~~ The special refractories can be divided into five categories: 1. metal ceramic

- Q:what's the classification of fireproof and thermal inuslation matertial?

- 1. thermal insulation material with A class combustion performance. Rock wool, glass wool, foam glass, foamed ceramics, foam cement, hole-closed perlite (2) thermal insulation material with B class combustion performance: extruded polystyrene board after special processing (XPS)/ polyurethane after special processing (PU) , phenolic aldehyde, gelatine powder polyphenyl granule. 3,thermal insulation material with B2 class combustion performance: molding polystyrene board(EPS), extruded polystyrene board(XPS), polyurethane (PU), polyethylene (PE),etc. sea capacity module and vitrified micro bead(cooperate with the innovator of vitrified micro bead, Liu Weihua) fireproofing issues have been completely solved.

- Q:What is the difference between the fire?rating and the fire resistant level of the fire-fighting equipment?

- Fire rating and fire-fighting rating are the misnomer to the building fire resistant level. The building fire risk is measured by fire resistant level. The article 3.2.1 and 5.1.7 of "Architectural design code for fire protection" have made provision respectively on the fire resistant level of plant (the storeroom) and civil construction. Article 3.0.2 of "Code for fire protection design of tall buildings" has made provisions on the fire resistant level of tall buildings. As for the warehouse building "category malonate", it refers to one of the fire risk of goods storage, which is divided into A, B, C, D, E, and each category is refined depending on the nature of different substances. "Malonate class" specified in article 3.1.3 of "building design for fire protection" refers to the flammable solid.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

2015 Hot Sale popular Silicon Carbide Recycle Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords