All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

Explain the properties and advantages of phosphate-bonded alumina in refractories.

Phosphate-bonded alumina is a type of refractory material that offers several properties and advantages. Firstly, it has excellent thermal shock resistance, meaning it can withstand rapid changes in temperature without cracking or breaking. This property makes it highly suitable for use in high-temperature applications such as kilns and furnaces.

Additionally, phosphate-bonded alumina has high chemical stability, allowing it to withstand corrosive environments and chemical reactions. It also exhibits good mechanical strength, ensuring its durability and longevity in industrial settings.

One of the main advantages of phosphate-bonded alumina is its easy installation process. It can be formed into various shapes and sizes, making it adaptable to different applications and requirements. Moreover, it has a quick and simple curing process, enabling faster production and reduced downtime.

Another benefit of phosphate-bonded alumina is its cost-effectiveness. It is a relatively inexpensive refractory material compared to other alternatives, making it an attractive choice for industries looking for efficient and budget-friendly solutions.

Overall, the properties and advantages of phosphate-bonded alumina in refractories make it a reliable and versatile material for high-temperature applications, offering thermal shock resistance, chemical stability, easy installation, and cost-effectiveness.

What are the advantages of using yttrium oxide as a raw material in refractory production?

One of the main advantages of using yttrium oxide as a raw material in refractory production is its high melting point, which allows refractory materials made from it to withstand extremely high temperatures without deforming or melting. Additionally, yttrium oxide has excellent thermal stability and chemical resistance, making it ideal for applications in industries such as metallurgy, ceramics, and glass manufacturing. Furthermore, yttrium oxide can enhance the mechanical strength and abrasion resistance of refractory materials, contributing to their overall durability and longevity.

What are the raw materials used in the production of unshaped refractories?

The raw materials used in the production of unshaped refractories include aggregates such as alumina, magnesia, silica, and clay, as well as binders like cement, lime, and sodium silicate. Other additives such as plasticizers, deflocculants, and stabilizers may also be used to enhance the properties of the refractory material.

How does the addition of bentonite affect the workability of refractories?

The addition of bentonite generally improves the workability of refractories. Bentonite is a clay mineral that acts as a binder and helps to enhance the plasticity and cohesiveness of refractory materials. It increases the water retention capacity, which aids in better mixing and compaction of the refractories during the manufacturing process. This improved workability allows for easier shaping and molding of the refractory materials, resulting in better quality and more precise final products.

Wholesale Raw Materials For Refractory from supplier in Zimbabwe

Our team of experts is well-versed in the unique requirements of the refractory industry in Zimbabwe. We understand the importance of high-quality raw materials for the production of refractory products, and we strive to provide you with the best options available in the market.

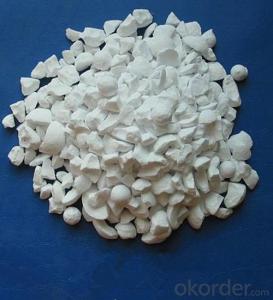

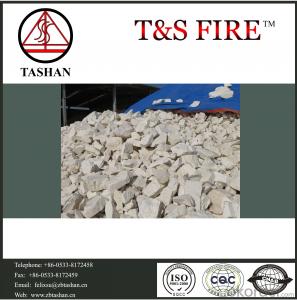

Whether you need materials for the manufacturing of bricks, castables, or other refractory products, we have got you covered. Our product range includes various types of refractory raw materials such as alumina, magnesia, silica, graphite, and more.

When you choose to work with us, you can expect efficient and reliable services. We offer sales assistance, providing you with competitive prices and ensuring prompt delivery of your orders. Our team is also available to provide you with quotations tailored to your specific needs, helping you to make informed decisions.

Furthermore, we understand that technical support is crucial in the refractory industry. Our team of experts is ready to assist you with any technical queries you may have, offering guidance and advice to help you achieve optimal results in your projects.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources, ensuring that you receive top-notch products and services. We are committed to your success and are dedicated to supporting your projects in Zimbabwe.

Contact us today to learn more about how we can assist you with your raw material needs for refractory products in Zimbabwe.

Whether you need materials for the manufacturing of bricks, castables, or other refractory products, we have got you covered. Our product range includes various types of refractory raw materials such as alumina, magnesia, silica, graphite, and more.

When you choose to work with us, you can expect efficient and reliable services. We offer sales assistance, providing you with competitive prices and ensuring prompt delivery of your orders. Our team is also available to provide you with quotations tailored to your specific needs, helping you to make informed decisions.

Furthermore, we understand that technical support is crucial in the refractory industry. Our team of experts is ready to assist you with any technical queries you may have, offering guidance and advice to help you achieve optimal results in your projects.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources, ensuring that you receive top-notch products and services. We are committed to your success and are dedicated to supporting your projects in Zimbabwe.

Contact us today to learn more about how we can assist you with your raw material needs for refractory products in Zimbabwe.

Hot Search

- Monolithic Refractories in Portugal

- Ceramic Fiber Products in Dominica

- Refractory Bricks in Niger

- Raw Materials For Refractory in Kuwait

- Ceramic Fiber Products in Bhutan

- Monolithic Refractories in Australia

- Ceramic Fiber Products in Vanuatu

- Raw Materials For Refractory in Belize

- Refractory Bricks in Belarus

- Ceramic Fiber Products in Iraq