2014 NEWES HEFEI SUDA newest engraving machine on promotion

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Condition: | New | CNC or Not: | CNC | Place of Origin: | Guangdong China (Mainland) |

| Brand Name: | LuckBerry | Model Number: | R-1618*6 | Voltage: | AC380V/50Hz |

| Power(W): | 1.5kw/2.2kw | Dimension(L*W*H): | 1500*1300*180mm | Weight: | 1500kg |

| Certification: | CE/ISO | Warranty: | 12months | After-sales Service Provided: | Engineers available to service machinery overseas |

| Net weight: | 1000kg | Spindle power: | 1.5KW | Spindle speed: | 6000-24000rpm/min |

| Working area: | 1600*1800*180mm | Diameter of cutter: | 3.175-16mm | Overall size: | 1600*1800*1500mm |

| Spindle quantity: | 6pcs | Spindle mode: | Water-cooling spindle | Max working speed: | 8m/min |

Packaging & Delivery

| Packaging Detail: | Standard Package: Thickness PE Foam inside ,poly film outside, wooden pallet is optional. |

| Delivery Detail: | 30 days after receiving down payment |

Specifications

R-1618*6 CNC Engraving Machine

1.Max working speed:8m/min

2.Spindle power:1.5KW water-cooling

3.Spindle speed:6000-24000rpm

R-1618*6-SG CNC Engraving Machine

Product Description

♦ Reference Picture of R-1618*6 CNC Engraving Machine :

♦ Specification of R-1618*6 CNC Engraving Machine :

Configuration of R-1618*6 CNC Engraving Machine:

| NO. | Detail Pictures | Items | Brand |

| 1 |  | Machine Structure | Cast steel body with aging & tempering treatment, solid and durable |

| 2 |

| T-Slot Worktable | T-Slot worktable clamp the workpiece directly, suit for small piece, cutting and hollow out processing. |

| 3 |

| Water-cooling Spindle | 6pcs * 1.5kw Hanqi Water-cooling Spindle

Strong Carving power, high precision, longer service life; Adopt grinding technology, can improve the motor concentricity, prolong service life.

|

| 4 |

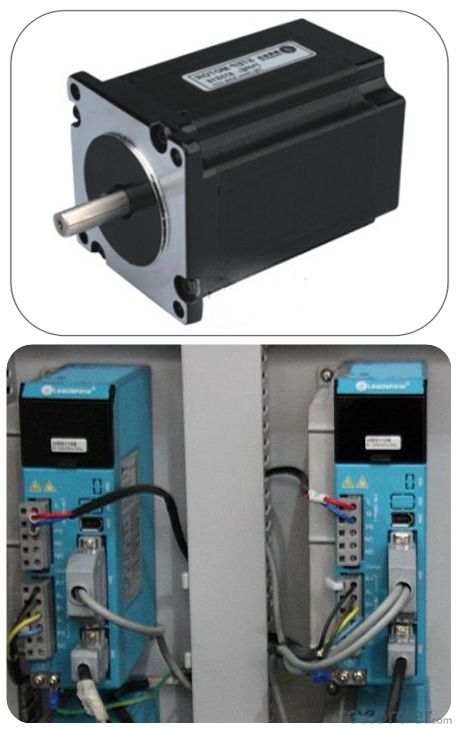

| Driving System | Leadshine Motor set with imported precision bearing, large torque, long working hours.

X,Y,Z axis drived by Leadshine driver, high resolution and positioning accuracy. |

| 5 |

| Transimission |

X,Y,Z axis adopt Taiwan AHK high precision preload anti-backlash ball screw, screw nut with tracking airtight dust removal device, guarantee the machine precision and service life.

|

| 6 |  | Guide Rail | Y axis adopt Taiwan Hiwin 20mm guide rail; X axis and Z axis adopts Taiwan Hiwin 20mm guide rail, adding scraping devices external and dust proof protection, extending the service life of the guide rail effectively. |

| 7 |

|

Electrical Component Breaker

|

Germany Schneider

|

| 8 | Frequency Inverter |

Sunfar Frequency Inverter

| |

| 9 | Electrical Compnent Cable | Special shielded cable drag chain special high flexible, can bend millions of times, drag chain support 150 degrees bend, effectively protect the cable. | |

| 11 | Approaching Sensor Switch | Dust proof, waterproof & antiseptic (3 pcs for X,Y and Z axis) | |

| 13 | Control System | Weihong System, visualization operation, real- time simulation, pretreatment ability | |

| 14 | Software Available | Artcam, Alphacam, Type 3, etc. CAD/CAM software compatible, identify G code, *.NC. | |

| 15 | Collect | 6 peice |

Workshop:

- Q:Woodworking engraving machine cutting panels, how seamless stitching?

- First, add 2 nodes at the file Y axis 1600, align, and then define the starting point at the new node, make a three-dimensional cutting path, observe the path, the machine starts processing;

- Q:The cupboard door engraving machine price how much money

- Hello, many kinds of engraving machine can do cabinet door, the most suitable is 1325 model three procedures woodworking engraving machine, ordinary 40 thousand or so

- Q:Which engraving machine is better in Northeast China? We feel how quanta force woodworking engraving machine?

- Engraving machine manufacturers now Trinidad and Tobago, the key lies in the quality of service and equipment, promised more, it was just clouds

- Q:How to properly maintain woodworking engraving machine?

- OilOiling plays an important role in the maintenance of woodworking engraving machines. The guide and lead screw after cleaning in oil; gas cycle is generally two weeks at a time; and after the oil will remember the slow walking back and forth, to ensure the lubrication of woodworking engraving machine; even though not long, but also regularly filling empty walk.

- Q:325 woodworking engraving machine, engraving 50mm thick MDF, need how much of the spindle, the Z axis travel what are the requirements? What knife do you need?

- Double edge straight groove knife, without slicing, ordinary density board single line cutting, then a knife can go down, I have not seen 50 mm, it is necessary to layered.

- Q:Large automatic CNC woodworking engraving machine, the general configuration of the current how much money?

- The size of machine tools, such as: 60901325, etc., the larger the machine tool, the more expensive the general price. You can also customize the type of machine according to your needs.

- Q:How to use the woodworking engraving machine carved false JD carved window, set the knife road how to get, and do not understand the arc inclined lane.

- You have to draw a 5MM high arc 2D line in the 2D line to the root surface section line generating surface generated so highly as you draw 2D line height is the same, if you don't understand what I'm saying is proposed to give up because things is not a short duration of time relief drawing

- Q:What kinds of engraving machines are there?

- According to the processing object and use different and can be divided into wood engraving machine, stone engraving machine, engraving machine, metal engraving machine, mold engraving machine engraving machine. On this basis, derived from a single head, a long, long branch independent engraving machine.Woodworking engraving machine engraving machine: the most species, according to the function can be divided into a wood processing center automatic tool change function and process of engraving machine, engraving machine with four axis stereo stereo engraving, woodworking engraving machine and ordinary derivative of the first single, independent, multi head carving. Machine generally adopts XY axis adopts rack drive, Z axis adopts screw drive, a woodworking engraving machine adopts screw drive, the main processing objects of the class name is wood engraving machine, mainly for: plate cutting, hollow, walking lace, relief engraving processing etc..

- Q:Woodworking engraving machine control system appears processing program error (third lines): the lack of parameters

- The post process file is not available

- Q:When did the woodworking engraving machine start?

- CNC woodworking engraving machine, is probably the last century the beginning of 60s, the beginning of Longmen CNC milling machine, at the beginning of 80s, Italy and Germany do batch used in this and later, Japan, followed by Taiwan Province, in fact, many of those called domestic woodworking engraving machine is advertising engraving machine PRO version.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

2014 NEWES HEFEI SUDA newest engraving machine on promotion

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords