PVC Coated Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

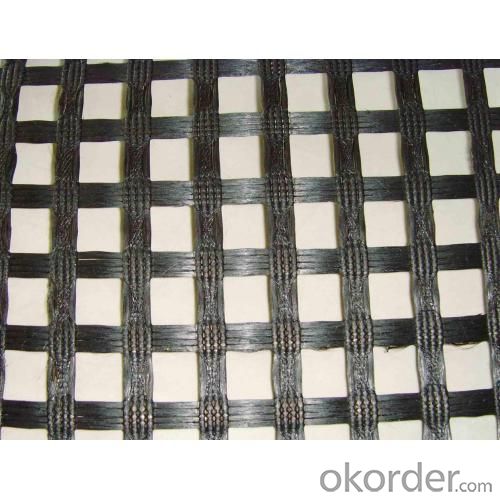

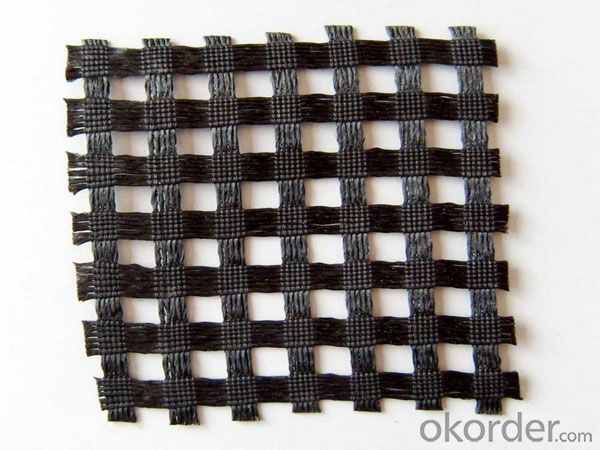

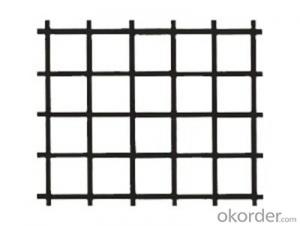

Structure of PVC Coated Geogrid Description:

PVC Coated Geogrid defined as a grid structure of polymeric material formed by weaving or knitting intersecting ribs with appropriate apertures (opening sizes) to allow interlocking with surrounding soil, rock, earth and other surrounding materials. There are two basic categories of geogrids. Uniaxial geogrids designed to endure stress in one direction. Their main strength is in the machine direction making these grids suitable for wall and slope applications.

Main Features of PVC Coated Geogrid

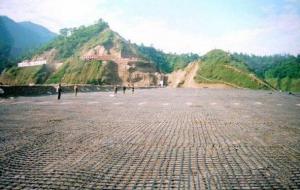

Improving bearing capacity of retaining wall or dam

Extending the project life

Reducing floor area

Shortening construction period, reducing cost and maintaining expense

PVC Coated Geogrid Images

PVC Coated Geogrid Specification:

Index Properties | Units | MD Values | XMD Values |

Aperture Dimensions | mm(in) | 25(1.0) | 33(1.3) |

Minimun Rib Thickness | mm(in) | 1.27(0.05) | 1.27(0.05) |

Tensile Strength @2% Strain | KN/m(lb/ft) | 6.0(410) | 9.0(620) |

Tensile Strength @5% Strain | KN/m(lb/ft) | 11.8(810) | 19.6(1,340) |

Ultimate Tensile Strength | KN/m(lb/ft) | 19.2(1,310) | 28.8(1,970) |

Junction Efficiency | % | 93 | |

Flexural Stiffness | Mg-cm | 750,000 | |

Aperture Stability | m-N/deg | 0.65 | |

Resistance to Installation Damage | %SC/%SW/%GP | 95/93/90 | |

Resistance to Long Term Degradation | % | 100 | |

Resistance to UV Degradation | % | 100 | |

Index Properties | Units | MD Values | XMD Values |

Aperture Dimensions | mm(in) | 25(1.0) | 33(1.3) |

Minimun Rib Thickness | mm(in) | 1.27(0.05) | 1.27(0.05) |

Tensile Strength @2% Strain | KN/m(lb/ft) | 6.0(410) | 9.0(620) |

Tensile Strength @5% Strain | KN/m(lb/ft) | 11.8(810) | 19.6(1,340) |

Ultimate Tensile Strength | KN/m(lb/ft) | 19.2(1,310) | 28.8(1,970) |

Junction Efficiency | % | 93 | |

Flexural Stiffness | Mg-cm | 750,000 | |

Aperture Stability | m-N/deg | 0.65 | |

Resistance to Installation Damage | %SC/%SW/%GP | 95/93/90 | |

Resistance to Long Term Degradation | % | 100 | |

Resistance to UV Degradation | % | 100 |

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2.Does your products have good qualitity?

A2:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q3:How long can we receive the products after purchase?

A3:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q:How do geogrids help in reducing construction costs?

- Geogrids help in reducing construction costs by providing reinforcement and stabilization to soil, allowing for the use of less expensive and lower quality materials. They also minimize the need for excavation, backfill, and compaction, resulting in reduced labor and equipment costs. Moreover, geogrids enhance the lifespan of structures by preventing soil erosion and settlement issues, reducing the need for costly repairs in the long run.

- Q:How do geogrids improve the stability of slopes?

- Geogrids improve the stability of slopes by providing reinforcement and preventing soil movement. They act as a barrier, distributing the forces exerted on the slope more evenly, reducing the risk of slope failure. Geogrids also increase the friction between soil layers, enhancing their shear strength and overall stability.

- Q:Why steel plastic geogrid in the test, will choose to peel out a single wire test? What are the causes and sources of this method

- Because the main force borne by the steel wire, if it is false, the consequences can be disastrous ah!

- Q:Geotextiles and geogrids to do the re inspection approach?

- If necessary, geotextile and geogrid materials are qualified. But it depends on the situation.

- Q:Can geogrids be used in railway construction?

- Yes, geogrids can be used in railway construction. Geogrids are commonly used to reinforce and stabilize the railway track substructure, providing improved load distribution and preventing soil movement. They help to increase the overall strength and stability of the track, making it more resistant to deformation and settlement. Additionally, geogrids can help reduce the maintenance needs of the railway infrastructure, making them a beneficial solution for railway construction projects.

- Q:How much is the tensile strength of Geogrid

- Warp knitting: 15KN--200KN, the highest foreign to 400KN.

- Q:Are geogrids resistant to microbial attack?

- Yes, geogrids are typically resistant to microbial attack.

- Q:What is the typical geogrid roll thickness for specific applications?

- The typical geogrid roll thickness for specific applications can vary depending on the specific project requirements and the type of geogrid being used. However, in general, geogrid roll thicknesses range from 0.5 mm to 3 mm.

- Q:Can geogrids be used in road widening projects?

- Yes, geogrids can be used in road widening projects. Geogrids are commonly used in road construction and rehabilitation projects as they provide a stable base, reduce soil movement, and improve the overall performance of the road. In road widening projects, geogrids can help reinforce the existing road structure, increase load-bearing capacity, and prevent the potential failure of the widened sections.

- Q:How much is the overlap length of Geogrid

- 10-15cm if the geogrid is a longitudinal lap not less than 20cm reference geogrid construction technology

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Coated Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords