PP Biaxial Geogrid with High Tensile Strength Direct Factory

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 10000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

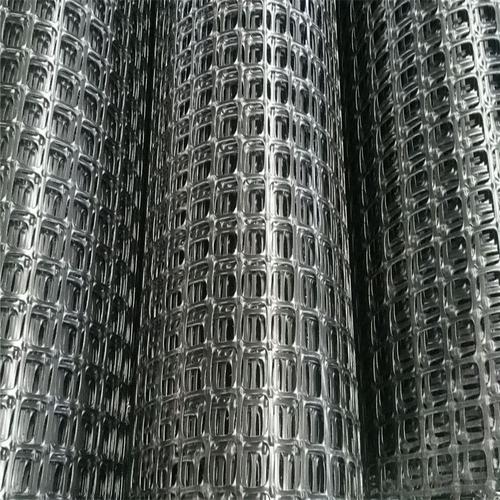

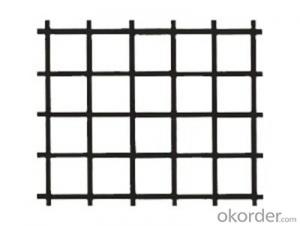

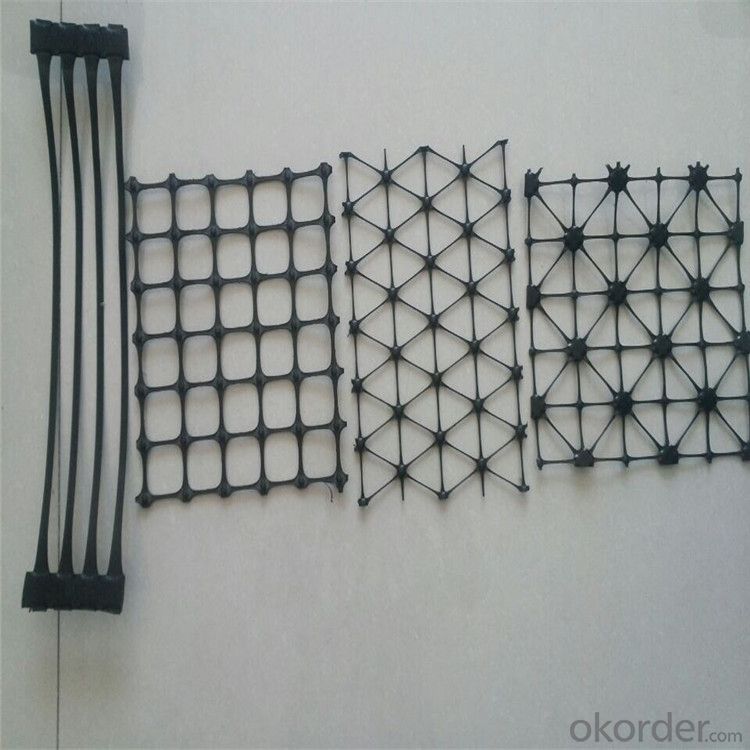

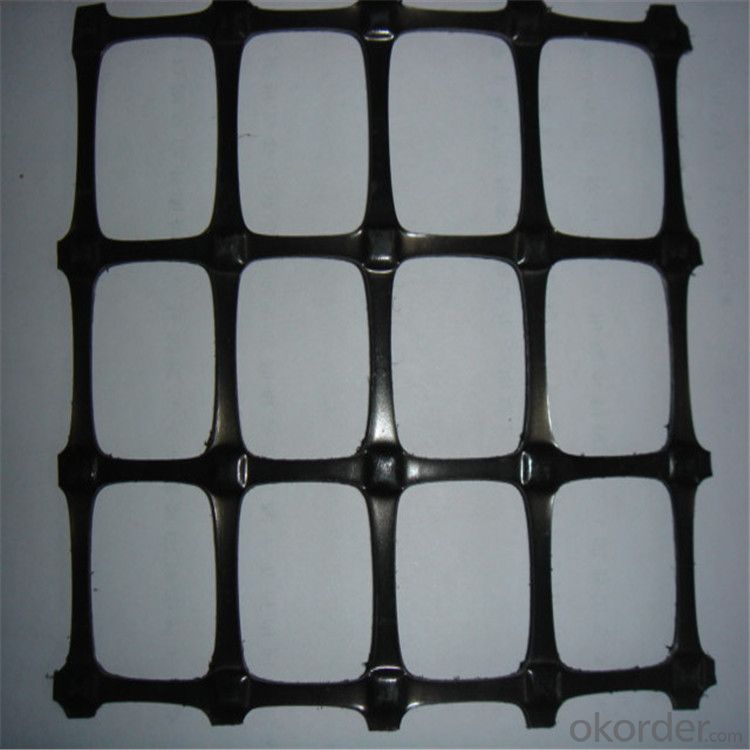

Biaxial geogrid, made of high molecular polymer, is extruded into sheet and then punched into regular mesh pattern, and finally stretched in longitudinal and transverse directions.

Properties of PP Biaxial Geogrid

Item Spec | TGSG 15-15 | TGSG 20-20 | TGSG 25-25 | TGSG 30-30 | TGSG 35-35 | TGSG 40-40 | TGSG 45-45 | TGSG 50-50 | ||

Tensile Strength ≧(Kn/m) | MD | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | |

TD | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | ||

Nominal Elongation ≦(%) | MD | 15 | ||||||||

TD | 13 | |||||||||

Tensile Strength at 2% Strain ≧(Kn/m) | MD | 5 | 7 | 9 | 10.5 | 12 | 14 | 16 | 17.5 | |

TD | 5 | 7 | 9 | 10.5 | 12 | 14 | 16 | 17.5 | ||

Tensile Strength at 5% Strain ≧(Kn/m) | MD | 7 | 14 | 17 | 21 | 24 | 28 | 32 | 35 | |

TD | 7 | 14 | 17 | 21 | 24 | 28 | 32 | 35 | ||

Junction Efficiency (%) | 93 | |||||||||

Width ≦(m) | 6 | |||||||||

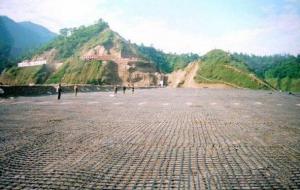

Images of PP Biaxial Geogrid

- Q:Are geogrids suitable for reinforcing railway subgrades?

- Yes, geogrids are suitable for reinforcing railway subgrades. Geogrids are specifically designed to improve the stability and strength of soil and can effectively distribute loads, reduce settlement, and prevent lateral movement. They are commonly used in railway construction and maintenance projects to enhance the performance of subgrades by providing additional support and increasing load-bearing capacity.

- Q:Are geogrids effective in preventing soil erosion on slopes without vegetation?

- Yes, geogrids are effective in preventing soil erosion on slopes without vegetation. Geogrids are synthetic materials that are designed to reinforce and stabilize soil, providing structural support to prevent erosion. They are commonly used in areas where vegetation is not present or cannot be established, such as construction sites or steep slopes. Geogrids improve soil stability, distribute load forces, and enhance water drainage, effectively reducing soil erosion.

- Q:Can geogrids be used in retaining wall reinforcement systems?

- Yes, geogrids can be used in retaining wall reinforcement systems. Geogrids are commonly used to enhance the stability and strength of retaining walls by improving soil retention and reducing lateral pressure. They provide additional support to the wall structure and prevent soil erosion, helping to increase the overall durability and longevity of the retaining wall.

- Q:What are the factors that affect the installation time of geogrids?

- There are several factors that can affect the installation time of geogrids. First and foremost, the size and complexity of the project play a significant role. Larger and more complex projects may require more time for planning, preparation, and execution. The type and condition of the soil also impact installation time. Soft or loose soils may require additional stabilization measures before the geogrids can be installed, which can extend the overall installation duration. Similarly, rocky or hard soils may require specialized equipment or techniques, which can also increase the installation time. The availability and accessibility of the site can also affect installation time. If the site is difficult to reach or has limited space for equipment and materials, it can slow down the installation process. Additionally, factors such as weather conditions, environmental restrictions, and safety considerations can further influence the installation time. Lastly, the experience and expertise of the installation team can greatly impact the efficiency and speed of the installation process. A skilled and experienced team can streamline the installation and overcome any challenges more effectively, reducing the overall installation time.

- Q:What are the advantages of using geogrids in ground improvement for seismic stability?

- Geogrids offer several advantages when used in ground improvement for seismic stability. Firstly, they provide increased strength and stability to the soil, enhancing its ability to withstand seismic forces. Geogrids can effectively distribute and dissipate the energy generated during an earthquake, reducing the risk of soil liquefaction and ground failures. Additionally, geogrids can improve the bearing capacity of the soil, allowing it to support heavier loads without experiencing settlement or failure. Furthermore, geogrids are easy to install and cost-effective compared to other ground improvement techniques, making them a viable solution for seismic stability in various construction projects.

- Q:How do geogrids improve the performance of geocomposite drains?

- Geogrids improve the performance of geocomposite drains by providing enhanced soil reinforcement and stabilization. They help to distribute the load from the surface and reduce stress on the geocomposite drain, preventing it from getting deformed or collapsing. Geogrids also increase the overall strength of the system, improving its longevity and efficiency in draining water or preventing soil erosion.

- Q:Are geogrids suitable for use in soil reinforcement for pipeline crossings?

- Yes, geogrids are suitable for use in soil reinforcement for pipeline crossings. Geogrids are commonly used in such applications due to their ability to effectively distribute loads, improve soil stability, and prevent soil erosion. They provide a cost-effective solution for enhancing the strength and durability of the soil, ensuring the safe and reliable installation of pipelines.

- Q:Can geogrids be used for slope stabilization?

- Yes, geogrids can be used for slope stabilization. Geogrids are commonly used in civil engineering to reinforce and stabilize slopes by providing tensile strength and improving the overall stability of the soil. They are effective in preventing soil erosion, reducing the risk of landslides, and ensuring the long-term stability of slopes.

- Q:What are the advantages of using geogrids in construction projects?

- Geogrids offer several advantages in construction projects. Firstly, they provide reinforcement to the soil, increasing its stability and load-bearing capacity. This helps to prevent soil erosion, slope failures, and settlement issues. Secondly, geogrids are cost-effective as they reduce the need for extensive excavation and the use of additional materials. They also facilitate faster construction time as they can be easily installed. Additionally, geogrids are durable and resistant to environmental degradation, ensuring long-term performance and reduced maintenance. Overall, the use of geogrids in construction projects leads to improved safety, enhanced structural integrity, and cost savings.

- Q:Can geogrids be used in landfill applications?

- Yes, geogrids can be used in landfill applications. Geogrids are commonly used in landfill construction to improve the stability and performance of the landfill liner system. They help in reducing the potential for soil erosion, enhancing the load-bearing capacity, and providing reinforcement to the liner system.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PP Biaxial Geogrid with High Tensile Strength Direct Factory

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 10000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords