Plastic Uniaxial Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

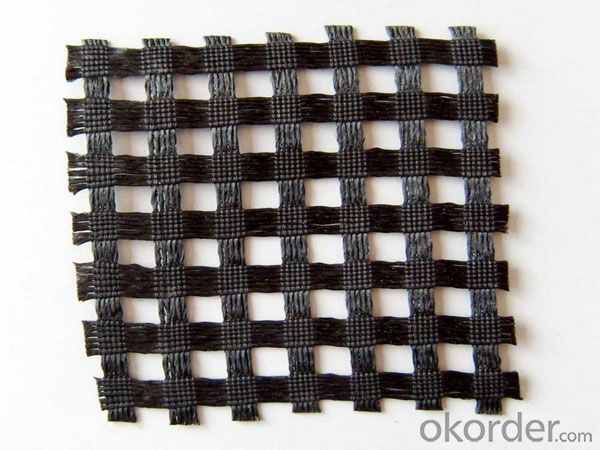

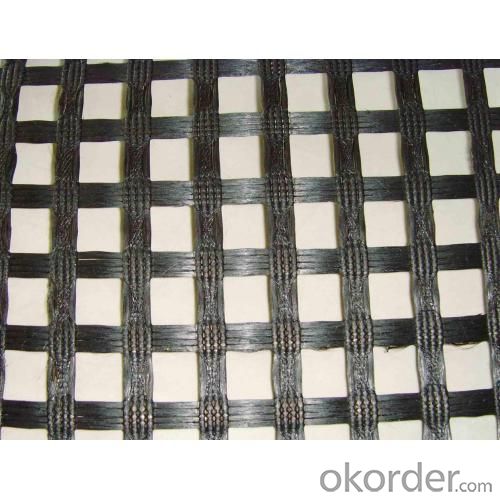

Structure of Plastic Uniaxial Geogrid Description:

Plastic Uniaxial Geogrid provide equal strengths in both machine and cross directions making them suitable for bases or foundation application where stresses can occur in any direction. Depending upon manufacturing techniques and materials, geogrids can be designed to resist creep when subjected to high loads for long periods of time or resist high, short-term dynamic loads or moderate loads over longer periods of time。

Main Features of Plastic Uniaxial Geogrid :

High tensile strength at low elongation

Optimized grid structure

Excellent pull-out and interface friction behavior

Superior connection capacity with modular blocks

Long durable years

High corrosion resistance

High flame retardancy,Fire prevention

High static conductive property

Easy in transport and installation..

Plastic Uniaxial Geogrid Images

Plastic Uniaxial Geogrid Specification:

1.Plastic Uniaxial Geogrid for Reinforced soil engineering(reinforced soil retaining wall, steep slope and the reinforcement and consolidation of the soft ground);

2.Road construction(ground treatment, reinforcement of the bridge abutment, reinforcement of the enbankment, reinforcement of the pile-net roadbed)

3. Geogrids for Irrigation projects(protection of port, approach lane, seabeach, channel, river channel, dam and other irrigation projects.)

4. Enviromental projects(land reclamation, prevention and controlling of the desertification,and the composite protective structure in the landfill sites of urban garbage and waste)

5. Mine engineering grid for long-wall recovery system(coal mines, side slope protection of opencast mines, slope protection for the dumping site of the opencast mines,reinforcement to counter dam in the large tailing ponds of the metallurgical mines)

6. Construction of stuffing and package system of heavy soil engineering

7. slope protection in the area affected by earthquake

8. Ground consolidation of large dump leaching sites and slag site

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2.Does your products have good qualitity?

A2:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q3:How long can we receive the products after purchase?

A3:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q:How do geogrids improve the stability of slopes?

- Geogrids improve the stability of slopes by providing reinforcement and enhancing the overall strength of the soil. They are typically installed within the slope to distribute stress and prevent soil movement, effectively reducing the risk of slope failure. Additionally, geogrids increase the bearing capacity of the soil, allowing for better load distribution and improved stability of the slope.

- Q:How do geogrids help in reducing the risk of soil erosion?

- Geogrids help in reducing the risk of soil erosion by providing reinforcement and stabilization to the soil. They are typically made of high-strength materials like polyester or polypropylene, which are resistant to degradation and can withstand heavy loads. When placed in soil, geogrids create a network of interconnected cells that increase the soil's resistance to erosion caused by water flow or wind. This reinforcement prevents the soil particles from being displaced, maintaining the integrity of the slope or embankment. Geogrids also improve soil drainage, allowing excess water to pass through and reducing the likelihood of erosion. Overall, geogrids act as a physical barrier against erosion forces, enhancing the stability and longevity of soil structures.

- Q:What are the procedures for using two-way geogrid

- 8 bidirectional geogrid construction methods: subgrade excavation, setting sand cushion (height of not more than 10cm), rolled into a platform, laying grille, longitudinal and main stress direction, the longitudinal joints 15-20cm, lateral 10cm, lashing plastic belt joint, and in the laying of the grille, every 1.5-2m with U the nail is fixed on the ground, laying geogrid should be timely backfill material, laying geogrid layers as technical requirements.

- Q:How are geogrids installed in construction projects?

- Geogrids are typically installed in construction projects by first preparing the ground surface and ensuring it is compacted and leveled. The geogrid is then laid out on the prepared surface and secured in place using stakes or anchor systems. It is important to ensure that the geogrid is properly tensioned and aligned to provide maximum stability and reinforcement. Finally, the geogrid is covered with additional layers of soil or other construction materials to complete the installation.

- Q:Are geogrids effective in preventing soil erosion on coastal cliffs?

- Yes, geogrids are effective in preventing soil erosion on coastal cliffs.

- Q:What is the significance of each index

- The slope on shop, should maintain a certain degree of tightness.Two)Geosynthetics shall be placed on each side of the embankment for a certain length, and shall be folded and wrapped in compacted fillOn the plane, the exposed part of the earth is covered by the soil.Three)When the joint of geosynthetics is used, the lap length should beThree hundred

- Q:What is the tensile strength of a geogrid?

- The tensile strength of a geogrid refers to its ability to withstand pulling forces without breaking or deforming. It is typically measured in units of force per unit width, such as kilonewtons per meter (kN/m). The actual tensile strength of a geogrid can vary depending on its design, materials used, and manufacturing process.

- Q:What are the design considerations for geogrid installation?

- Some key design considerations for geogrid installation include selecting the appropriate geogrid material and type based on the specific project requirements, considering the soil and subgrade conditions to ensure proper installation and performance, determining the appropriate geogrid placement and orientation to maximize stability and load distribution, and ensuring proper connection and anchoring of the geogrid to adjacent structures or soil to prevent movement. Additionally, factors such as site preparation, construction techniques, and long-term maintenance should also be taken into account during the design process.

- Q:What kind of projects are used to detect the geogrid

- Geogrid conventional testing includes

- Q:Technical specifications of glass fiber grating

- Temperature (c) -100~280 -100~280 -100~280 -100~280 -100~280 -100~280 -100~280 (m) 1.5~4.0 1.5~4.0 1.5~4.0 width 1.5~4.0 1.5~4.0 1.5~4.0 surface treatment of 1.5~4.0 modified asphalt modified asphalt modified asphalt modified asphalt modified asphalt modified asphalt modified asphalt with excellent corrosion resistance excellent excellent excellent excellent excellent excellent

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Plastic Uniaxial Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords