Geogrid Uniaxial

Geogrid Uniaxial Related Searches

Led For Cannabis Growing Fiberglass Sheets For Roofing Geogrid For Road Construction Geogrid For Erosion Control Geogrid For Soil Stabilization Geogrid For Horse Paddocks Geogrid For Gravel Geogrid For Pavers Geogrid For Steep Slopes Geogrid For DrivewaysHot Searches

Geogrid China Geogrid Mesh Price Geogrid Fabric Price Geogrid Roll Price Geogrid Price List Tensar Triax 160 Geogrid Price Tensar Ss40 Geogrid Price Tensar Tx160 Geogrid Price Triax Geogrid Price Geogrid Price Tx160 Geogrid Price Geogrid Fabric Home Depot Plastic Flower Buckets Wholesale Wholesale Plastic Hanging Baskets Plastic Planter Liners Wholesale Tensar Type 2 Geogrid Type 2 Geogrid Home Depot Geogrid Fiberglass Scaffolding For Sale Fiberglass Panels For SaleGeogrid Uniaxial Supplier & Manufacturer from China

Okorder.com is a professional Geogrid Uniaxial supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Geogrid Uniaxial firm in China.Hot Products

FAQ

- Classification and application of polyethylene geogrid?

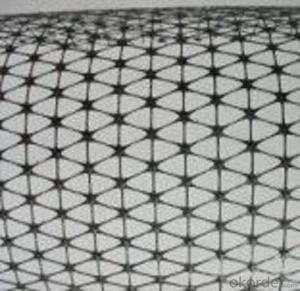

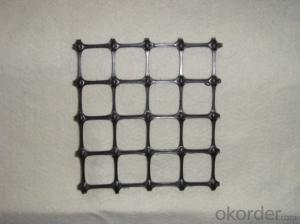

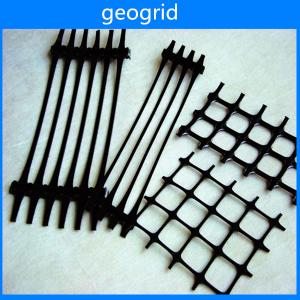

- Polyethylene geogrid is divided into four categories: plastic geogrid, steel plastic geogrid, fiberglass geogrid and polyester warp knitted polyester geogrid

- The lifespan of a geogrid can vary depending on factors such as the quality of the material, environmental conditions, and the level of stress it experiences. However, with proper installation and maintenance, geogrids can typically have a lifespan of 20 to 50 years.

- Yes, geogrids are suitable for use in saline environments. Geogrids are typically made of high-strength polymers that are resistant to corrosion and degradation caused by saline environments. Additionally, they have been extensively used in coastal and marine engineering projects where they are exposed to saltwater and have shown excellent performance and durability. Therefore, geogrids can be a reliable and effective solution for reinforcing soil structures in saline environments.

- What way to quickly cut the geogrid

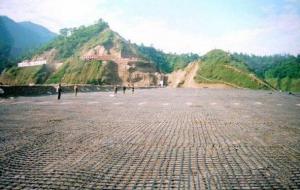

- 3, one-way geogrid for reinforcing the dam and road slope and retaining wall: the traditional embankment especially filling high embankment filling and often need to shoulder edge easy compaction, resulting in slope rainwater invasion, collapse phenomenon, at the same time with a gentle slope, covers an area of large, retaining wall have the same problem with Geogrid embankment slope or retaining wall reinforcement can be reduced by two points a area, prolong service life, reduce the cost of 20 - 50%.4, one-way geogrid to reinforce the River seawall: made of stone cage, with the grid and use, prevent the dam washed collapse, stone cage is permeable and can reduce the impact of the waves, prolong the life of the dam, save manpower, shorten the construction period.

- Yes, geogrids can be used in erosion control on slopes and hillsides. Geogrids are designed to reinforce and stabilize soil, preventing erosion and improving slope stability. They are commonly used in various erosion control applications, including on slopes and hillsides, to enhance the structural integrity of the soil and reduce the risk of erosion.

- Geogrids improve soil stability by providing reinforcement and confinement to the soil, helping to distribute and transfer loads more evenly. They interlock with the soil particles, increasing the shear strength and preventing soil movement and erosion. Additionally, geogrids can enhance the load-bearing capacity of the soil, allowing for more efficient construction and reducing the risk of slope failures or settlement.

- What are the types of geogrid, respectively, what role?

- Glass fiber geogrid is a kind of excellent geosynthetic material used for Pavement Strengthening, strengthening of old road, strengthening subgrade and soft soil foundation. It has become an irreplaceable material in the application of reflective cracking in asphalt pavement. The product is made of high strength alkali free glass fiber through international advanced warp knitting process made of mesh substrate, the surface coating processing made of semi-rigid products. With the warp and weft two-way high tensile strength and low elongation, and high temperature resistance, low temperature, aging resistance, corrosion resistance and other excellent properties, is widely used in the asphalt pavement, cement concrete pavement and subgrade reinforcement and railway roadbed, dam slope, airport runway, anti sand control project.

- Geogrids help in reducing the risk of pavement rutting by providing structural reinforcement to the pavement layers, improving their stability and preventing the formation of ruts. They distribute the load across a wider area, reducing the stress on the pavement surface and minimizing the deformation caused by heavy traffic or repeated loading. This helps to maintain the integrity of the pavement, increasing its lifespan and reducing the need for costly repairs or maintenance.