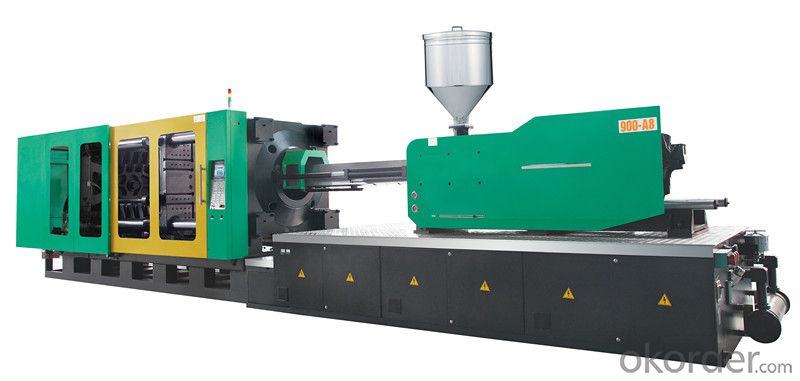

Injection Molding Machine LOG-900A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

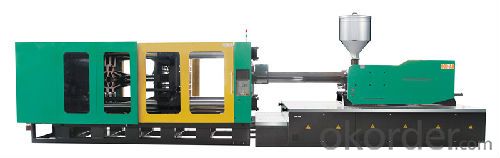

Type: Tube Head Injection

Style: Horizontal

Brand Name: LOG MACHINE

Model Number: LOG900-A8

Place of Origin: Zhejiang, China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 2893-5143g

Clamping Force: 9000kn

Opening Stroke: 1050 mm

Power(W): 37+37 kw

Certification: CE ISO9001

After-sales Service Provided: Engineers available to service machinery overseas

Voltage: 380V

Space between Tie Bar: 1080*1030

Platen size: 1530*1530

Heating power: 58.45 kw

Oil Tank Capacity: 1900 L

Machine weight: 48T

Screw Diameter: 90-100-110-120

Ejector stroke: 300 mm

Ejector force: 270 kn

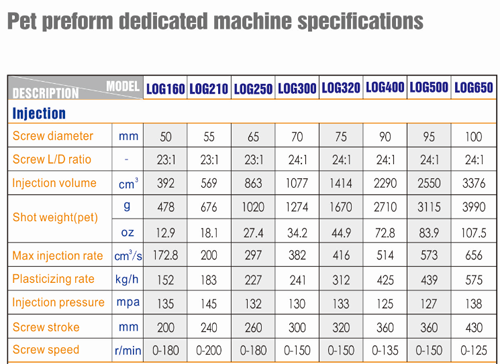

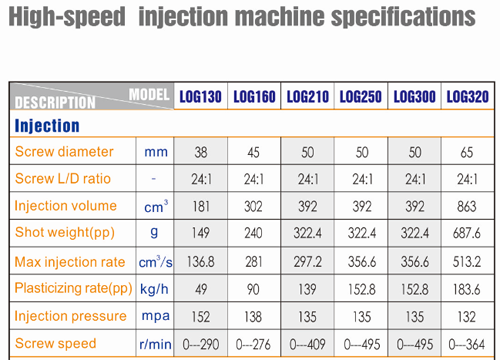

| INJECTION | LOG900 | ||||

| A | B | C | D | ||

| Shot volume | cm³ | 3179 | 3925 | 4750 | 5652 |

| Shot weight (ps) | G | 2893 | 3571 | 4321 | 5143 |

| oz | 103 | 127 | 153 | 182 | |

| Max injection rate | cm³/s | 540 | 666 | 806 | 960 |

| Screw diameter | Mm | 90 | 100 | 110 | 120 |

| Plasticizing rate | Kg/h | 291 | 378 | 503 | 600 |

| Injection pressure | Mpa | 227 | 184 | 152 | 128 |

| Screw L:D ratio | 22:01 | 22:01 | 20:01 | 18.3:1 | |

| screw speed | r/min | 0-120 | |||

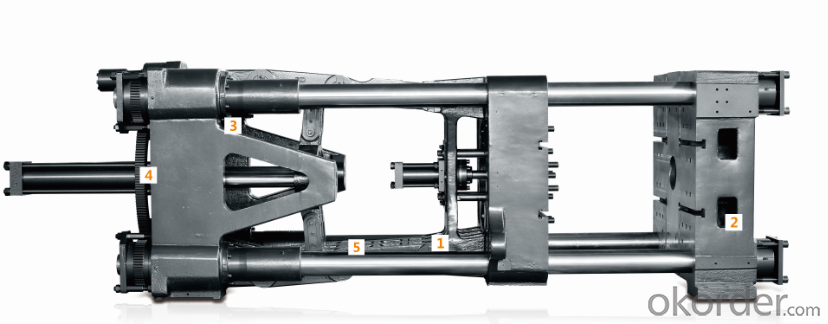

| CLAMPING | |||||

| Clamping force | Kn | 9000 | |||

| Opening stroke | Mm | 1050 | |||

| Platen size | MmXmm | 1530*1530 | |||

| Space between tie bars | MmXmm | 1080*1030 | |||

| Mold thickness (Min-Max) | Mm | 400-1100 | |||

| Hydraulic ejection stroke | Mm | 300 | |||

| Hydraulic ejection force | Kn | 270 | |||

| Power Unit | |||||

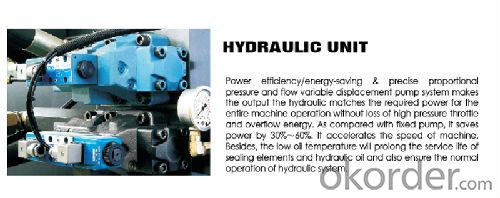

| Hydraulic system pressure | Mpa | 17.5 | |||

| Pump motor | Kw | 37+37 | |||

| Heating capacity | Kw | 58.45 | |||

| Number of temp control zones | 6+ (nozzle) | ||||

| GENERAL | |||||

| Dry-cycle time | sec | 8 | |||

| oil tank capacity | L | 1900 | |||

| Machine dimensions | Mxmxm | 11*2.4*3.5 | |||

| Machine weight | kg | 48000 | |||

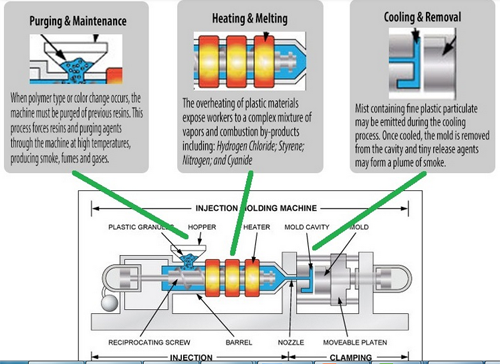

Common thermoplastic resins include:

Polyethylene PE

Polyvinyl Chloride PVC

Polypropylene PP

Polystyrene PS

Polyethlene Terephthalate PET

Acrylonitrile-butadiene-styrene ABS

Styrene-Acrylonitrile SA

Acrylic PMMA

Polyamide PA (Nylon)

Styrene-Acrylonitrile SAN

Polycarbonate PC

- Q:General injection molding machine agents need what conditions?

- DKM injection molding machine agent basic requirements: with injection molding machine sales experience, and has a certain after-sales maintenance capabilities

- Q:Debugging and debugging process of injection molding machine

- (2) products shrinkFault reason handling methodInsufficient mold penetrationThe amount of melt is not enough, plus the amount of melt adhesiveLow glue pressure, low pressureHigh back pressure back pressure is not enoughInjection time too short injection timeInjection speed is too slow or fastThe overflow is uneven and the overflow of the mold is too small or in placeThe nozzle hole is too thin, plastic in the sprue bushing in solidification, reduce the back pressure effect. Adjust the mold or replace the nozzleMaterial temperature is too high and material temperature is lowImproper temperature and proper temperatureThe cooling time is not enough to prolong the cooling timeWhen the pressure storage section is too large, the adhesive shall terminate at the front endThe product itself or its ribs and columns are too thick to review the finished product designExcessive injection of glue to replace the finer injection molding machineWear removal of apron and adhesive screwGate is too small, plastic solidification loss, back pressure action, increase gate size

- Q:What is the function of the temperature control box of the injection molding machine? Thank you

- Controlling the temperature of two heating tubes.Chasing the answerThe temperature is too high and too low, the thermostat plays the role of switch heating tube power supply.The heating tube is used to warm the mold

- Q:Plastic injection molding machine barrel diameter is how many centimeters or millimeters?

- 2 inch inch diameter is in inches (25.4 inches per inch), such as 3/16,5/8,1/4,1/2, and so on, so the use of metric calipers, external diameter readings, often with irregular decimals.

- Q:Advantages and disadvantages of horizontal injection molding machines and vertical injection molding machines?

- 1. horizontal machine has the advantages of high operation, convenience, high safety performance, large bearing size and so on. The disadvantage is that the floor space is large and the price is relatively high. Suitable for medium and large moulds.2. vertical machine has the advantages of small footprint, relatively low prices, shortcomings, such as high gravity, inconvenient to take parts, etc., suitable for small molds.

- Q:Production calculation... 60 / 60 seconds * / / 25 x 32 / sec / mold die =1 * 12 hours per hour yield = 12 small classInjection molding machine... Production calculation... 60 / 60 seconds * / / 25 / 32 / sec * die die =1 output * 12 hours = 12 hour shifts production 55075But I don't get enough output every day... Can only do 49501 pieces, ask 49501 pieces to take several hours to be able to do... How much extra time do I have to add to the production?... Urgent urgent... Can not take a day except what count how much time yield......

- 1. are you fully automated? If it's fully automated, then you'll be able to record each exception from minutes to minutes, so you know your abnormal hours. If it is semi-automatic production, it depends on the boot staff, the door is not stable, this can be seen inside the injection molding machine.

- Q:What is the fluctuation of the screw speed of injection molding machine?

- Screw speed adjustment of injection molding machineThe extruder screw speed and yield the direct proportion between tsuen. This shows that increasing the screw speed can greatly increase the extrusion yield, but from the angle of stable extrusion, it puts forward higher requirements for the control of screw speed fluctuation. The conventional single screw extruder mostly adopts the transmission mode of the ordinary V belt and gear change. Theoretical analysis shows that the elastic slip of the V belt occurs during the operation of l%-1.6% and causes the loss of rotation. Foreign high pin single screw extruder has adopted the direct connection of motor and reducer, and cancelled belt drive.Influence of type and control method of the motor on the extrusion process stability can not be ignored, at home and abroad in recent years extruder host using DC motor or motor, the motor electromagnetic speed compared with the previous working stability of these two kinds of machines has been greatly improved, the FV (vector volume) of AC variable frequency motor control represents the most the new transmission technology. Now, through the use of variable frequency speed regulation machine, with a special extruder for plastic extruder, the screw speed fluctuation can be controlled at about 0.01%.Dongguan Huahong Plastic Machinery Factory suggested that we should adopt it

- Q:Why should the central feed system be used in the injection molding workshop?

- First, the central feed system is automated, can save people, facilitate management, improve production, and now it is not easy for enterprises to recruit individuals, and each enterprise wants to find the best employees.Second the central feeding system has many advantages such as visual, raw materials, recycling materials in switching (material) by mixing, drying, color and so on.Third, the central feeding system integration, reduce workshop covers an area, can make workshop cleanliness and beauty enhancement, and promote enterprise image

- Q:What products can be produced by injection molding machine?

- Injection molding machine, also known as injection molding machine or injection machine. It is a thermoplastic or thermosetting plastic plastic molding mold made of plastic products of all shapes of the main molding equipment. It is divided into vertical, horizontal and all electric type. The injection molding machine heats the plastic, applying high pressure to the molten plastic to make it crack and fill the mold cavity.Different injection molding products require different molds. Because the shape of each injection product is different. So do not have the same mold.The injection molding machine is the same. Just like we make cookies, bear cookies use bear shaped molds, rabbits, rabbit shapes, and so on,But the oven is the same. You can use the same one!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Injection Molding Machine LOG-900A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords