Injection Molding Machine LOG-160A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

A8 CONFIGURATIONS

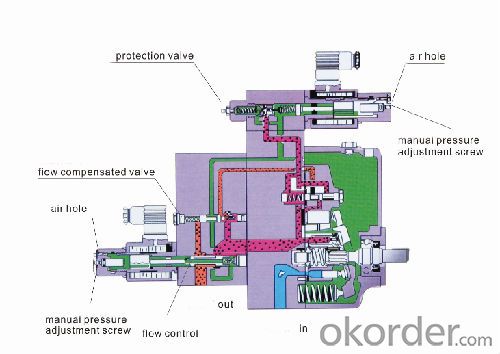

PROPORTIONAL VARIABLE PUMP YUKEN

OIL MOTOR INTERMOT

DIRECTION VALVE VICKERS

COMPUTER MIRLE 9118

AC CONTACTOR SCHNEIDER

ELECTRONIC RULER NOVO

LUBICATION PUMP HERG

Quick Details

Condition: New

Type: Other

Style: Horizontal

Brand Name: LOG

Model Number: LOG-160A8

Place of Origin: China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 260---368G

Clamping Force: 1600KN

Opening Stroke: 430MM

Power(W): 15kw

Certification: CE

After-sales Service Provided: Engineers available to service machinery overseas

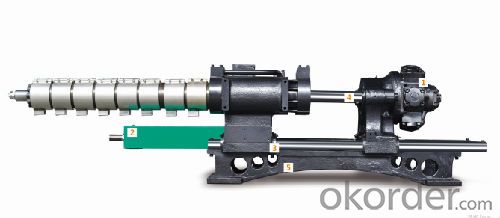

LOG160-A8 energy-saving plastic injection moulding machine

| Description | Unit | LOG-160A8 | ||

| international recognized models | 525/160 | |||

| injection | A | B | C | |

| Tjeoretical injection volume | cm³ | 277 | 318 | 392 |

| Shot volume | g | 260 | 298 | 368 |

| Oz | 9.1 | 10.5 | 12.9 | |

| Screw diameter | mm | 42 | 45 | 50 |

| Injection diameter | mpa | 190 | 166 | 135 |

| Screw L:D ratio | 21.4:1 | 20:01 | 18:01 | |

| Scerw steoke | mm | 200 | ||

| Screw rotate speed | r/min | 0-200 | ||

| CLAMPING UNIT | ||||

| Clamping force | kN | 1600 | ||

| Opening stroke | mm | 430 | ||

| Platen size | mm*mm | 680*680 | ||

| Space between tie bars | mm*mm | 460*460 | ||

| Maldthickness | mm | 180-500 | ||

| Platen Mix stroke | mm | 930 | ||

| Ejection stroke | mm | 140 | ||

| Ejcetion force | kN | 50 | ||

| Power/Elcetric Heating | ||||

| Hydralic system pressure | Mpa | 17.5 | ||

| Pump motor | kw | 18.7 | ||

| Heating power | kw | 12.6 | ||

| Number of temp.conteol | 4+nozzle | |||

| Other | ||||

| Cycle time | sec | 2 | ||

| Tank volume | L | 210 | ||

| Machine dimesions | m*m*m | 4.95*1.25*2.0 | ||

| Weight of machine | kg | 5100 | ||

- Q:Can polyurethane (PU) material be molded by injection molding machine?

- Polyurethane is divided into three categories, 1, thermosetting casting (CPU); 2, thermoplastic extrusion (TPU); 3, MPU (mixed type).TPU can be injected with an injection molding machine. CPU and MPU can't be injection molded.

- Q:Injection molding machine pressure, speed, back pressure unit is what and their relations with other international units

- Pressure injection molding machine, we often talk about the pressure, strictly speaking, the pressure is equivalent to the middle school, which bear the force per unit area, the international regulations, under 1N in the area of 1 square meters (Newton) on the pressure of 1Pa (Pascal), as long as know the multiple relation, it is easy to obtain the pressure (strong the conversion unit):1m=100cm=1000mm1kg = 10N1M (megabit, million) Pa=1MPa=1000k (1000) Pa=1000000PaSo 1MPa=10kg/cm^2=1N/mm^2We often use international non legal units of measurement: 1bar=10^5Pa=1kg/cm^2=0.1MPa (bar) and 1Torr=133Pa (Torr)The pressure gauge of the injection molding machine, the most used is MPa, bar, kgf/cm^2 unit, need to be reminded that, behind the two units is not our statutory units of measurement, but the world especially Europe and the United States is often used, because many components of the injection molding machine for imported components, including the pressure gauge, so we will often see illegal dial pressure gauge measurement units.In the injection molding machine, the injection molding machine pressure and back pressure unit is MPa, speed (actually refers to injection rate), the unit is g/s, or cm^3/s

- Q:What kind of metal material is the nozzle head of injection molding machine?

- The injection head of the injection machine is the material of No. 45 steelNozzle specifications must be confirmed: total length, diameter of tooth, distance between teeth.All kinds of nozzles, spring nozzles and split nozzles for injection molding machinesThe thread has M18*2.5,M22*2,M24*2, M24*2 lengthenedM30*2, M30*2 lengthenedM30*3, M30*3 lengthenedM36*2, M36*2 lengthened,M36*3, M36*3 lengthenedM39*2, M39*2 extended specialtyM39*3, M39*3 lengthened special skillsM42*3, lengthenM45*2And so on all kinds of specifications, various length sizes. Special specifications must be ordered ~ systemThe difference between a split nozzle and a spring nozzle

- Q:What do you mean by the "starting position and time" of the injection molding machine?.

- When injection is converted to holding pressure, it is determined by time or position. If the location, the general set pressure holding position is about 5% of the storage position.

- Q:How is the screw speed of injection molding machine adjusted? Who knows very well?.

- Injection molding machine screw speed, first, adjust the injection molding machine pre molding pressure and flow, and then adjust the back pressure

- Q:How much is a new injection molding machine, mainly mobile phone shell?

- Look at the brand, 100T models, domestic cheap, prices do not know

- Q:What do you mean by the number of beers produced by an injection molding machine?

- Hello landlord!In this case, "beer" refers to the products (including nozzles and products) that are taken out after the molding machine has been formed at once. This is usually a 1*1 hole number, a beer products =1 products; if it is 1*2 hole number, then a beer =2 products, and so on, and so on.And if it is two-color machine, then the molding is two times after a beer, the other is the same

- Q:What kind of after-sales service, which friends know to introduce?

- I knowChasing the answerThe best thing is the company's low pressure injection molding machine, and many famous brands are looking for them to process low voltage injection molding machines, such as apple, Microsoft, and the United states.

- Q:How to reset the EM-120 origin of the injection machine?

- 6, locking machine to machine hinge straight;7, repeat third steps;8, enter 1 at the default mode 1; move the cursor back to preset 1; appear as input Press confirm again;9, enter 2000 at the preset mode 2;10, repeat the lock die 3 to 4 times to the machine hinge straight, see the actual value of the lock more than how many; 2000 minus the remaining numberValue; enter preset 2;11, reset the high pressure die termination position and adjust the clamping force to the die.

- Q:What does injection pressure mean?

- Five, the adjustment of back pressureThe adjustment of the injection back pressure shall be determined according to the raw material performance, drying conditions, product structure and quality, and the back pressure should be adjusted at 3-15kg/cm 3. When the surface of the product has little Qihua, mixed color, shrink and product size and weight changes, may be appropriate to increase the back pressure. When the nozzle leakage glue, salivation, Melt Overheating product decomposition, discoloration and feeding back too slow may be considered appropriate to reduce the back pressure.Back pressure is one of the important parameters to control melt quality and product quality in injection molding process. Proper back pressure plays an important role in improving product quality, and can not be ignored!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Injection Molding Machine LOG-160A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords