EPS and Rockwool Sandwich Panel Line

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 set set

- Supply Capability:

- 100 set per month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

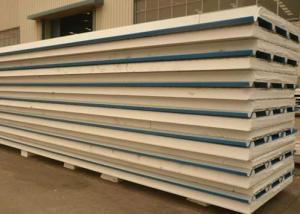

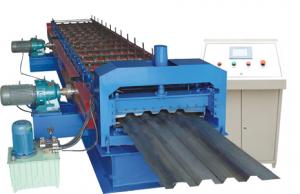

General Information of Sandwich composite panel line:

We can design the line to make different kinds of panel in appearance, for wall panels and roofing panels with various joint design. Sandwich panel, as a new building material show excellent performance on insulation. It is taking the place of brick to be a main material for building now.

Specifications of EPS and Rockwool Sandwich Panel Line

The whole line consists of uncoil device, forming system, cutting device, compounding system(beading, pasting, heating ,compounding, flanging, slotting, edging, pneumatic and auto-cutting).

Features of Sandwich composite panel line:

1. Adopting advanced technology, it combines air, electricity and machine system.

2. Adopting computer control stepless speed regulation, it is smooth in running and easy in operation.

3. According to customers' requirement, the length is controlled by the computer, with an accurate orientation.

4. Time is showed on the touch screen, counting and revising automatically.

5. The outline of the panel can be designed and revised on customers' requests.

Applications of Sandwich composite panel line:

This metal forming machine is indispensable equipment for producing the wall panel and roof panel for industrial workshops, warehouses etc.

Technical Data of Sandwich composite panel line:

1. The Manufacture Speed Of Sandwich Panel:0-4.05m/min

2. The Thickness Of Sandwich Panel:50-250mm

3. The Exterior Dimension Of The Product Line : length×width×height, 56000×4500×2800

4. The Total Capacity Of The Product Line : 50kw

5. The Output Of the Sandwich Panel:1500-2000m2/8 hours

Packaging & Delivery of Sandwich composite panel line:

1. Main machine is covered by plastic film.

2. PLC computer control box, spare parts and other small parts are packed by wooden carton box.

3. Delivery:80 days

- Q:What do you want to consider if you want to buy a sandwich panel production line?

- Now the mainstream is rock wool board, but now the profit is not high, other equipment is still in the monopoly of foreign countries, I don't know what kind of you produce, but I hope you can produce new varieties.

- Q:How is the sandwich plate synthesized?

- The finished products of the sandwich panel are easy to install, light and efficient. The filling system also uses the closed bubble molecule structure to prevent the condensation of water vapor.

- Q:Can the oil on the sandwich board be painted?

- When spraying, the thinner is easy to penetrate into the plate, the sandwich board is glued laminated board, it is easy to dissolve the glue, the separation of the layer.

- Q:Color tile and color steel sandwich plate what is the difference, the use of what is the difference?

- Color steel sandwich panel is a common product in building materials, not only good flame retardant, sound insulation, but also environmental protection and high efficiency. The color steel sandwich panel is composed of two layers: metal panel and middle layer macromolecule insulation core. The utility model has the advantages of simple installation, light quality, environmental protection and high efficiency. Moreover, the structure of the closed bubble used in the filling system can prevent the condensation of water vapor.

- Q:Rock wool, color steel sandwich plate production line where good?

- Company's R & D and production of rock wool polyurethane sandwich board equipment, rock wool, /EPS color steel sandwich board equipment, can produce all kinds of different types of fire insulation board.

- Q:How to thread the EPS (color steel) sandwich panel?

- It depends on understanding! It is always more difficult than the way!

- Q:Can the sandwich board adhere to the plaster line?

- First brush on white latex (polyvinyl acetate emulsion), and then self tapping nails will be fixed on the wood board gypsum board, silk nail head must be slightly concave into the gypsum board, so as not to destroy the plaster board surface of the layer of paper for the most appropriate

- Q:How can the wire laying in the foam sandwich panel workshop meet the fire protection requirements?

- The phone line is best separated from the signal power line and there will be interference. Fire broadcasting is usually 110V voltage, the need for separate piping. Can be divided into points as far as possible, to avoid future difficulties in troubleshooting.

- Q:What's the difference between a polyurethane sandwich panel and a foam sandwich panel?

- The common point is that the sandwich panels are all made of hard protective coatings, and the difference is that the materials in the center are different.

- Q:What are the causes of uneven surface of polyurethane sandwich panel produced by continuous production line?

- The upper and lower track plates of the fixed polyurethane plate are not smooth, mainly because of the processing problem, the chain drive polygon effect or the equipment level is not adjusted properly;

1. Manufacturer Overview |

|

|---|---|

| Location | Hebei, China |

| Year Established | 2007 |

| Annual Output Value | Below US$1 Million |

| Main Markets | 23.41% Eastern Europe 20.29% Southeast Asia 16.91% Mid East 11.68% Africa 11.00% South America 8.74% North America 4.30% Eastern Asia |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Xingang Port |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Low and/or Average |

Send your message to us

EPS and Rockwool Sandwich Panel Line

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 set set

- Supply Capability:

- 100 set per month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords