Automatic Auger Filling Machine for powder and granular

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of the Automatic Auger Filling Machine

This Machine is a complete, economical solution to your filling production line requirements.can measuring and filling powder and granular. It consists of the Filling Head, an independent motorized chain conveyor mounted on a sturdy, stable frame base, and all necessary accessories to reliably move and position containers for filling, dispense the required amount of product, then quickly move the filled containers away to other equipment in your line (e.g., cappers, labelers, etc.).it fits more to the fluidic or low-fluidity materials, like milk powder, albumen powder, pharmaceuticals, condiment, solid drink, white sugar, dextrose, coffee, agriculture pesticide, granular additive, and so on.

2. Features

- Lathing auger screw to guarantee the precise filling accuracy

- PLC control and touch screen display

- Servo motor drives screw to guarantee stable performance

- Quick disconnecting hopper could be washed easily without tools

- Can be setting to semi-auto filling by pedal switch or auto filling

- Full stainless steel 304 material

- weight feedback and proportion track to materials, which overcomes difficulties of filling weight changes due to materials’ density change.

- Save 20 sets of formula inside the machine for later use

- Replacing the auger parts, different products ranging from fine powder to granule and different weight can be packed

- Multi language interface

3. Technical parameters

First type-Liner type

| Model | TP-PF-A21 | TP-PF-A22 |

| Control system | PLC & Touch Screen | PLC & Touch Screen |

| Hopper | Quick disconnecting hopper 25L | Quick disconnecting hopper 50L |

| Packing Weight | 10 - 5000g | 10 - 5000g |

| Dosing mode | Directly dosing by auger | Directly dosing by auger |

| Paching accuracy | ≤500g, ≤±1%; >500g,≤±0.5% | ≤500g, ≤±1%; >500g,≤±0.5% |

| Filling speed | 15 - 40 times per minute | 15 - 50 times per minute |

| Air supply | 6 kg/cm² 0.05m³/minute | 6 kg/cm² 0.05m³/minute |

| Power supply | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz |

| Total power | 1.6 KW | 1.6 KW |

| Total weight | 300 kg | 300kg |

| Overall Dimensions | 2000*970*2030mm | 2000*970*2300mm |

Second type- Rotary type

| Model | TP-PF-A301 | TP-PF-A302 |

| Hopper volume | 25L | 50L |

| Container size | φ20-100mm; H15-150mm | φ30-160mm; H50-260mm |

| Control system | PLC & Touch screen | PLC & Touch screen |

| Packing weight | 1 - 500g | 10 - 5000g |

| Packing accuracy | ≤100g, ≤±2%; 100-500g,≤±1% | ≤500g, ≤±1%; >500g,≤±0.5% |

| Filling speed | 20-50 bottles per minute | 20-40 bottles per minute |

| Power supply | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz |

| Total power | 1.2 KW | 2.3KW |

| Air supply | 6kg/cm² 0.05m³/minute | 6kg/cm² 0.05m³/minute |

| Total weight | 160kg | 260kg |

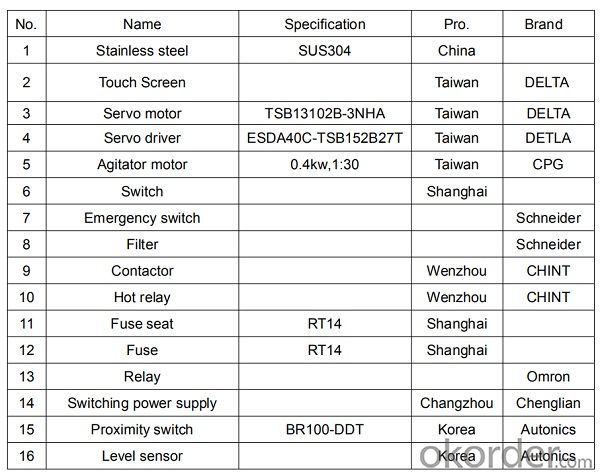

4. Configuration list

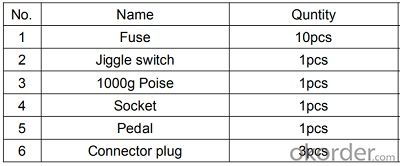

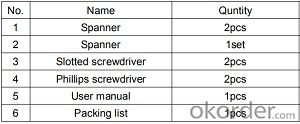

Accessories

Accessories tools

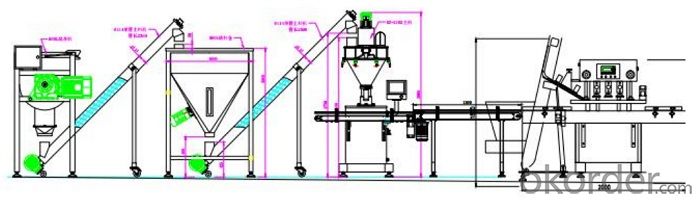

5. Image of fonction

6. Remark

- Delivery Period: 25 days after receipt of down payment

- Payment Terms: 30%T/T as deposit + 70%T/T balance payment before delivery.

- Guarantee Period: 12 months

- Package: seaworthy plywood carton

- Q:What is the transport theory in logistics management?

- It is. The moving activity index is used to represent the active parameters of items in various states. Handling process step, should be designed to make the activity of the materials or goods index gradually increase (or at least reduce), which is called the activation step by step. Use active exponent to handling the activity of high and low, handling of active index of high handling method is a better way

- Q:Why is the material advanced air cold and water cooling in the design of the device

- So, water cooling can be cooled to a lower temperature (and air-cooled ratio), so it will be used in the back. The return water temperature of circulating water should not be too high, otherwise it will scale. If it can achieve cooling, it is preferable to save money and save money

- Q:How is the information flow of the material handling system implemented?

- A set of material storage and transportation system that can carry the workpiece and the tool between the workstations of the machine. FMS is a programmable manufacturing system that contains automatic material delivery equipment that enables information integration and logistics with the support of computers...

- Q:Ask for material handling robot design report

- Now to * * * * provided free of charge is the prototype of the robot from the plane, surface, on the steps, or wheels powered by power with the feet, you don't have to like Honda robot behind bear power battery; Of tsinghua university, Dr Robot professional to work in Beijing jiaotong university after manufacture and displayed on the (shenzhen robot also towing power supply cable, and environmental protection, and innovation, also put forward the new method of raider buggies competition; * * * is a display of patriotism, defense, military and science popularization of education. As to surpass foreign flight simulator XunLianCang, can produce a controllable * * * equipment foundation information, has been notified to the * * * *, can be produced in the nearby enterprises, with himself informed, have not seen the similar device. You can also instruct the student to write the invention patent application document (the university intellectual property course and the patent attorney don't teach you!) All this is the hard way to raise ticket prices.

- Q:The parameters of the powder materials transport vehicle

- Tanks using automatic longitudinal welding process, weld formation, tanks use straight-through type or Y type fluidized bed to optimize the external and internal structure of tank, low center of gravity, large volume and other characteristics; The design scientific layout is reasonable, the unloading time is short, the remaining grey rate is low. It is suitable for the transportation and unloading of powder coal ash, cement, lime powder, mineral powder, etc. It is used in double cone, double cone, double pipe inlet and double barrel feed. The material and metal accessories are treated with shotblast, with strong adhesion, good corrosion resistance and uniform paint film, which can withstand all kinds of bad environment. The capacity of the tank is 25 to 40 cubic meters.

- Q:There is no quarterly material transfer label. How do you analyze it in 5

- Plan the flow of information along with the flow of physical flow. Schedule the production and send the processing/outsourcing parts to the follow-up workshop and the post-process, and feedback the actual performance to the planning department. This is a predominantly planning "pusher" logistics management mode, but because of various kinds of interference factors, external demand fluctuations, often running inside often also have exception occurs, all kinds of lead time forecast is not accurate, "plan change lag", leading to each workshop, process between the material quantity and variety in cohesion, the delivery date is hard to meet deadlines. In order to resolve these contradictions, such measures as rapid adjustment plan, safety inventory and emergency feeding are usually adopted. In fact, in production logistics, the enterprise must choose the appropriate management style with the characteristics of its products and production. Other companies often combine the strengths and weaknesses of the above, adopting hybrid strategies such as ERP and JIT management.

- Q:The horizontal distance from the outside edge of the elevator platform and the unloading platform should not be greater than that

- Material hoist hanging scaffold platform (also called construction lifter lifting cage) and unloading platform construction scaffolding each floor of the mouth or platform, in order to ensure safety construction, two platform where the horizontal spacing should be not greater than 50 mm.

- Q:What are the components of an automated three-dimensional warehouse?

- Integrated warehouse technology is regarded as the center of material storage in the Integrated Manufacturing System (cims-computer Integrated Manufacturing System). Although the system has been observed in the 1980s, there are not many integrated storage systems in our country. The three phases are the basis for the integration of people, equipment and control systems. In the early 1970s, our country began to study the stereoscopic warehouse of the roadway stacker. In 1980, the first automatic three-dimensional warehouse, which was developed by the Beijing institute of mechanical industry automation, was put into operation in Beijing automobile manufacturing plant. Since then, the warehouse has developed rapidly in our country. According to the incomplete statistics, our country has built a three-dimensional warehouse nearly three hundred, of which there are more than 30 fully automatic three-dimensional warehouses. Our country's automatic warehouse technology has realized the integration of other information decision-making system, and is doing the research work of intelligent control and fuzzy control

- Q:The stability of material lift machine mainly depends on which parts of the material hoist

- The cable line should be set when there is no condition to set up the attached wall. Wire rope must be used. (4) anchor force of the anchor, the location of the buried directly influences the effect of cable wind rope, when choosing cable wind rope anchor point, depending on its soil conditions, decided to form and practice of anchor.

- Q:What kind of equipment is the material handling equipment

- Locate the handling equipment. The equipment is used to process materials in a single position so that they can be processed, processed, transported and stored in the right place. Transport equipment and location devices are typically used for processing in a single workplace. The material can also be used manually with no equipment positioning. The unit load forms the handling equipment. The equipment is used to limit the material so that they maintain their integrity when processing a load on transport and storage. If the material is self-constraining (for example, a single or interlocking portion), then they can form a unit load without the device.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Automatic Auger Filling Machine for powder and granular

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches