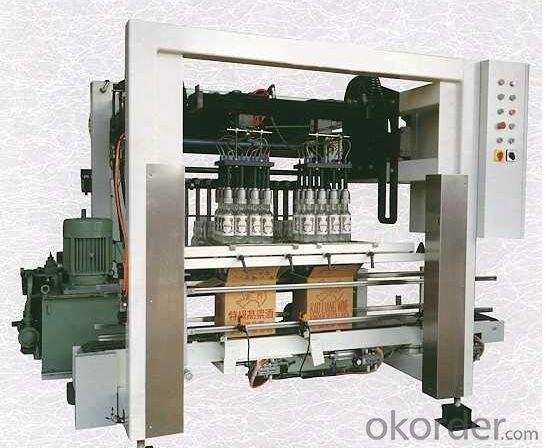

YZX Series Crate Packer/YCX Series Uncrater YZX4

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Descriptions

CMAX Packing is a professional company specializing in R & D, manufacturing, technical service and sales of beer and beverage packing machinery.

Among the products, RCGF series, CGF series, DCGF series bottle packing and QGF series barrel packing beverage production lines and QHS series beverage mixer are all designed and made on the base of importing the advanced technology from German, Italy and Japan and its technology keeps the same level as international.

Also the company provides technical consultation, factory planning, installing and adjusting technological train and other services.

YZX series crate packer/YCX series uncrater:

Usage:

The kind of machine is suitable for bottling beverage or beer production line of crate packing and uncrating working procrdure ,which cn fit for different bottles and crates through changing colllet module and bottle-rising&falling frame.

Crate packing is mainly made up of bottle-comveying,crate-conveying,bottle-arranging,bottle-gripping,double four linking pole,bedplate,pneumatic equipment,electric PLC control etc.

Uncrater is mainly made up of bottle-conveying,crate-conveying, crate conveying,bottle-hripping,double-four linking pile,bedplate,pneumatic equipment,clectric PLC control etc.Equitment,electeric PLCcontrol etc.

Specifications

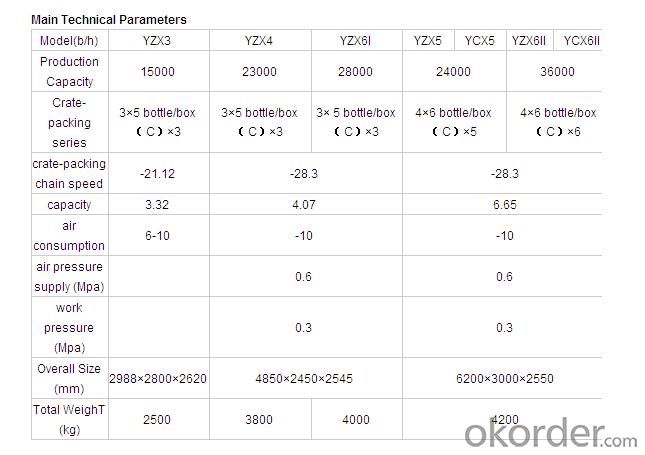

Model(b/h) | YZX3 | YZX4 | YZX6I | YZX5 | YCX5 | YZX6II | YCX6II |

Production Capacity | 15000 | 23000 | 28000 | 24000 | 36000 | ||

Crate-packing series | 3×5 bottle/box(C)×3 | 3×5 bottle/box(C)×3 | 3× 5 bottle/box(C)×3 | 4×6 bottle/box(C)×5 | 4×6 bottle/box(C)×6 | ||

crate-packing chain speed | -21.12 | -28.3 | -28.3 | ||||

capacity | 3.32 | 4.07 | 6.65 | ||||

air consumption | 6-10 | -10 | -10 | ||||

air pressure supply (Mpa) | 0.6 | 0.6 | |||||

work pressure (Mpa) | 0.3 | 0.3 | |||||

Overall Size (mm) | 2988×2800×2620 | 4850×2450×2545 | 6200×3000×2550 | ||||

Total WeighT (kg) | 2500 | 3800 | 4000 | 4200 | |||

FAQ:

1. why chose us?

China National Building Materials (Group) Corporation (CNBM), established in 1984,now is one of the largest state-owned group corporation in China, dealing with building materials & industrial equipment. Up to year 2010, CNBM Group's total asset is 20 billion USD and total staff is more than 100,000.CNBM International Corporation, specializes in designing & manufacturing of various

kinds of construction machinery, including tower crane, building hoist, etc. All the equipment produced by CNBM are compliant with the National level quality standard, and wins great reputation for their endurable performance in worldwide markets.

2.How about the shipment?

The delivery time is 20 days.

3. What about your service?

We have our factory, we can meet customers needs as soon as possible.

We have first rate professional technology and provide good after-sales service.

4.After Sales Service

We offer the Preventative Maintenance and After Sales Service. For we strongly feels about the importance of supporting our customers and the product solutions we provide. Consequently we offer comprehensive maintenance options to prevent equipment issues before they become problems. Also we offer one year guarantee period.

- Q: What is the design basis of automated packaging?! Just for today!

- Increase productivity and reduce process costGerman packaging machinery, especially beverages, beer filling machinery and food packaging machinery, with high speed, complete sets, high degree of automation and good reliability and so on. Beverage filling speed up to 1200 bottles / D, when the cigarette packaging 12000 / min.. Increasing the speed of the machine is a complex problem. The faster the piece production cost is, the higher the use area of the workshop is. In addition, the speed of the motor is limited, so do not think how fast, how fast. In general, the speed increase by 15%, 20%, will lead to a series of complex problems. In addition to increasing the speed, the productivity can be solved from other channels:1. continuous or long work. Packaging machinery works a batch type and continuous type, design, design should strive for continuous work, also can improve the productivity; one device may also have multiple production lines, the production of the same product or several different products, but must improve the reliability.2. reduce scrap rate and provide fault analysis system. The loss of waste to production is enormous, not only product loss, but also material loss. So try to force to reduce the rejection rate; packaging machinery sale should also provide maintenance services for the fault analysis system, the modal analysis is carried out to find fault, or through the Inter network for remote diagnosis, the maximum to meet customer needs. In the future, the packaging machinery will be further intelligent, that is, the equipment itself to find fault, to solve their own failure, to reduce waste rate and failure rate, so that the normal productivity can be improved.

- Q: The difference between wrapping and bagging is explained from the packaging method, and the difference of the working principle of the packaging machine is analyzed

- Wrapping of objects of different shapes according to their appearance.

- Q: What is the price of a small jujube packing machine?

- What is the price of a small jujube packing machine?

- Q: Color code positioning of packaging machinery

- The use of the printed color packaging materials, photoelectric switch (available on the color electric eye tracking and positioning), through the control system to drive the stepper motor rotation and color according to the distance between the automatic stop, to complete and accurate packaging products logo.

- Q: Food packaging process is not standardized, there is no responsibility?! For example, after the production of candy, because there is no corresponding packaging equipment, the need for artificial packaging

- Yes, automatic packing machine. I'm an employee of the automatic packaging machinery company.

- Q: How is the production and characteristics of ceramic wall tiles different from the size and performance of molding?

- What is the size of the parison forming pressure and the performance of the ceramic wall and floor tile products?Ceramic wall and floor tiles are usually formed by pressing. Domestic made for 30 tons, imported equipment has tons of suppression, 200 tons and 500 tons. In order to smooth accurate size, excellent products, must pay attention to the effect of powder properties and compression of products. That is to say, the quality of the floor tiles, billets, methods of preparation, and the quality of products and production scale and way of pressing machinery. As for pressing pressure, as the molding pressure decreases, the sintering shrinkage becomes smaller and the water absorption rate becomes smaller, the durability of the product should be improved. It should be noted that the pressure should not be too high. Excessive pressure, stress, and density increase will cause unnecessary energy consumption, and cause compressed air to expand after pressure is canceled and cause excessive spalling.

- Q: What is the delay time of the packer's cross sealing?

- There is also a delay in the end of the last movement of the machine to the beginning of the sealing action.

- Q: Whether you can press paper plastic molding after PET

- Sure;Note cards must be coated with plastic oil;Can use blister sealing machine or high frequency plastic welding machine hot pressing;

- Q: What are the packaging machines that use temperature control watches?

- Such as shrink machine, vertical packaging machine, pillow type packaging machine, continuous sealing machine,

- Q: Three dimensional packaging machine, transparent film packaging machine, transparent film three-dimensional packaging machine industry standards

- This standard specifies the terms and definitions, models, types and basic parameters, technical requirements, test methods, inspection rules and signs, packaging, transportation and storage requirements of the three-dimensional packaging machine for transparent film.

Send your message to us

YZX Series Crate Packer/YCX Series Uncrater YZX4

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords