YFD Series Turned-up Bottle Sterilizer YFD15

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Chenyu Packing is a professional company specializing in R & D, manufacturing, technical service and sales of beer and beverage packing machinery.

Among the products, RCGF series, CGF series, DCGF series bottle packing and QGF series barrel packing beverage production lines and QHS series beverage mixer are all designed and made on the base of importing the advanced technology from German, Italy and Japan and its technology keeps the same level as international.

Also the company provides technical consultation, factory planning, installing and adjusting technological train and other services.

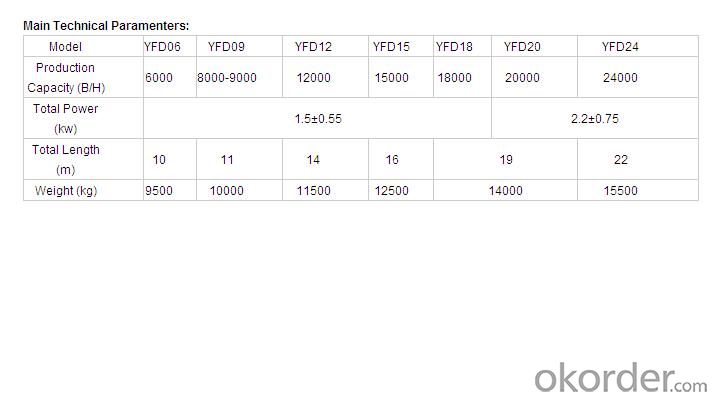

YFD Series Turned-up Bottle Sterilizer:

Usage: This kind of sterilizer is that the angle of bottle overturns to 96°or 110°in the process of transporting bottle ,and then the beverage uses its high temerature(higher than 80°)after filling to give the caps the final sterilization, the sterilizing time can be adjusted in the scope of 30-40sec.as the requirement.Adopting imported stainless steel chain and enduering high temperature plastic chain board.With the excellent features of compacted structure,convenient operation,and saving energy,this kind of machine is the best choice for tea,fruit juice hot filling cap-sterilizing product line.

- Q: The role of food packaging machinery

- 3) to achieve manual packaging can not achieve the operation, some packaging operations, such as vacuum packaging, inflatable packaging, body packing, isobaric filling, etc., are manual packaging can not be achieved, can only be achieved by mechanical packaging.(4) can reduce labor intensity, improve the working conditions of the labor intensity of manual packaging, such as volume, weight heavy manual packaging products, both the consumption of physical strength, and safety; and for small and light products, due to high frequency, easy to make the action monotonous, worker occupation disease. Carton folding machine(5) in favor of labor protection for some serious impact on health products, such as serious dust, toxic products, irritating, radioactive products, manual packaging is a health hazard, and packaging machinery can be avoided, and can effectively protect the environment from being polluted.(6) it can reduce the cost of packing and save the storage and transportation expenses. It can reduce the volume and reduce the packing cost by compressing and packing the loose products, such as cotton, tobacco leaf, silk and hemp. At the same time, due to the reduction of large volume, in order to save storage capacity, reduce storage costs, is conducive to the transport.(7) ensure product health of certain products, such as food and drug packaging, according to the health law is not allowed to use manual packaging, because it will pollute the products and packaging machinery to avoid direct contact with the staff of food and medicine, to ensure the quality of health.

- Q: What is the general packing cost of beer beverage packaging?

- In addition, according to the product's own conditions to set, the packaging machine prices are generally in the range of 3-5 yuan

- Q: Predecessors please point out: what is the future of packaging machinery industry?

- Hello, in recent years, Chinese packaging industry, although the annual growth rate ranked in the traditional industry for the first time, but in line with the international market, to accelerate the development of packaging technology, make its development to the economic, efficient, multi-functional direction. According to the development plan of Chinese national economy and to realize well-off life level, this year a few years for the packaging industry, the food industry to provide equipment for 100 billion yuan to 200 billion yuan, 80 billion yuan to 100 billion yuan to provide equipment for the "vegetable basket", this is a good opportunity for development of enterprises. At the same time, I learned from the relevant ministries, "95" period, will invest 10 billion yuan in the packaging industry to support and transform large and medium-sized packaging enterprises.

- Q: What are the main plastic forming processes?

- Plastic processing is a complex process, generally divided into the following processing methods:In order to improve the quality of the product and improve the molding efficiency, the pre pressing is used to press the powder or fibrous molding material into a certain shape in advance.Preheating, in order to improve the processing performance and shorten the molding cycle of molding plastics, the molding plastics are heated prior to molding.Molding in the mold to add the required amount of plastic, closed mold and exhaust, at the mold temperature and pressure to maintain a period of time, and then release mold cleaning operations

- Q: Packaging machine knife cut out of the mouth is uneven, always inclined, so adjust, now tune not come back, or is unable to cut off, or die!

- . This is the importance of after-sales service. Qingdao Xun packaging machine models, can meet the needs of all levels.

- Q: What's the best place to use the pillow type packing machine?

- Suggest that manufacturers can find communication, there is no technical strength,

- Q: Food packaging process is not standardized, there is no responsibility?! For example, after the production of candy, because there is no corresponding packaging equipment, the need for artificial packaging

- Yes, automatic packing machine. I'm an employee of the automatic packaging machinery company.

- Q: Which friend is an expert in mechanical equipment or a better understanding of sealing machines? Tell me how to identify the equipment

- Take the food packaging machine for example, if only from the hardware, then you can ask when you buy the degree of automation, semi-automatic or fully automatic, the use of steel ah,

- Q: Food, equipment, tools, containers, packaging materials, etc. shall comply with food safety standards or requirements

- Graphic symbols for packaging and storageGB/T 5009.60. Analytical method for hygienic standard of polyethylene, polystyrene and polypropylene moldings for food packaging

- Q: Calendering, extrusion, blow molding, pressing, plastic (vacuum forming) and what is the rotational molding

- Plastic forming and processing methodPlastic molding is an engineering technology, involves the plastic into all kinds of plastic products in the process. The transformation process tends to happen in one or more of the following conditions, such as polymer rheology and physical and chemical properties of the change.

Send your message to us

YFD Series Turned-up Bottle Sterilizer YFD15

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords