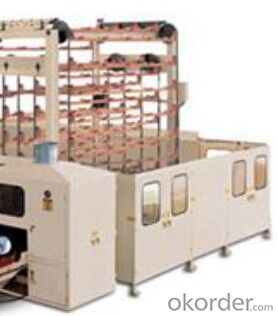

YD-PL350E Non-stop JRT/Industrial Roll Rewinding Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

This line is the newest model which is upgraded on base of our quondam automatic re-winder and foreign technology.

A lot of advanced control technology are used in this line,such as: Program Logic Control System;HMI,;one button Chinese-English switch;synchronous frequency conversion drive;integration of mechanics,electrics and photo.It is equipped with whole trouble information.It can detect and adjust every action of the rewinder automatically to keep the rewinder in optimal situation.For example:There is a web tension system in the line,It can control speed according to the tension of web so it can adapt different type of jumbo roll.So it is the best choice to produce JRT/Industrial roll for paper company. The characteristics of the rewinder are as follows:

1、Unwind is equipped with closed loop frequency conversion control system.

2、When the webs do not align,you can operate on the touch button screen to move the jumbo roll till webs align.

3、When the core unit can not detect core or core will use up, the machine will alarm to tell operator or workers to put some cores on the core bracket.

4、When the machine is running, web break off suddenly for reason of speed change sharply of problem from jumbo roll.

5、Degree of tightness can be adjusted while a log is rewinding.It can produce different degree of tightness in one log.

6、When a log is rewinding,the next core is ready.

7、For the reason of using advanced technology:Program Logic Control System; synch-ronous frequency conversion drive;integration of mechanics,electrics and photo.

8、When the finished log come to tail sealer, trimming, glue spraying and sealing can be finished at the same time.

9、embossing unit and glue applicator、edge embossing unit、printing system is order by customer.

ITEM | 2900 |

Jumbo roll width(mm) | 2850 |

Dimension | Depend on the model and configuration |

Weight | Depend on the model and configuration |

Jumbo roll diameter(mm) | ≤Φ2000(>Φ2000 to order) |

Jumbo roll core diameter | Φ76mm(other size to be specified) |

Finished product dimension | Φ150-280mm |

Finished roll core size(mm) | Φ76 |

Perforation pitch | 4blades:90~160mm(other size to be specified) 2blades:180~320mm(other size to be specified) |

Perforation | 2/4PCS sprial upper perforated |

Rewind | Non-stop |

Parameter setting | HMI |

Finished roll rewinding | Very convenient for with core and coreless interchange |

Control system | PLC,inverter,integration of mechanic,electrics and photo |

Web tension system | Encoder,PLC,inverter |

Transmission system | Gear,timing belt,flat belt |

Compressed air | 0.5~0.8MPa(customer provide) |

Machine speed | Design speed: 350m/min, Produce speed: 300m/min |

Unwind stand | 1-3ply(to be specified),independent drive |

option | |

Embossing unit | Steel to rubber embossing,point to point embosser with lamination,nested embosser with lamination,deco embosser with lamination |

Edge embossing | Steel to steel |

Printing unit | 1~2colors(customer provides pattern) |

Automatic seal unit | Automatic positive web-cut inside and automatic sealing outside machine |

- Q: The role of food packaging machinery

- 3) to achieve manual packaging can not achieve the operation, some packaging operations, such as vacuum packaging, inflatable packaging, body packing, isobaric filling, etc., are manual packaging can not be achieved, can only be achieved by mechanical packaging.(4) can reduce labor intensity, improve the working conditions of the labor intensity of manual packaging, such as volume, weight heavy manual packaging products, both the consumption of physical strength, and safety; and for small and light products, due to high frequency, easy to make the action monotonous, worker occupation disease. Carton folding machine(5) in favor of labor protection for some serious impact on health products, such as serious dust, toxic products, irritating, radioactive products, manual packaging is a health hazard, and packaging machinery can be avoided, and can effectively protect the environment from being polluted.(6) it can reduce the cost of packing and save the storage and transportation expenses. It can reduce the volume and reduce the packing cost by compressing and packing the loose products, such as cotton, tobacco leaf, silk and hemp. At the same time, due to the reduction of large volume, in order to save storage capacity, reduce storage costs, is conducive to the transport.(7) ensure product health of certain products, such as food and drug packaging, according to the health law is not allowed to use manual packaging, because it will pollute the products and packaging machinery to avoid direct contact with the staff of food and medicine, to ensure the quality of health.

- Q: What are the main functions of packaging machinery?

- Eight main functions of packaging machinery and equipmentPacking is a necessary condition for products to enter the circulation field

- Q: What are the main plastic forming processes?

- 5. low pressure molding. A touch or laminating method using a molding pressure equal to or less than 1.4 mpa.Low pressure molding is used to make reinforced plastic products. Reinforced materials such as glass fiber, textiles, asbestos, paper, carbon fibers, etc.. Most resins used are thermosetting, such as phenolic, epoxy, amino, unsaturated polyester, silicone and other resins.Low pressure molding includes bag pressing and spraying.(1) bag pressing forming. A method of forming a workpiece by applying fluid pressure to an elastomeric plastic between a rigid mold and an elastic bag by means of an elastic bag (or other flexible diaphragms). According to the different methods caused by fluid pressure, can generally be divided into pressure bag molding, vacuum bag molding and autoclave molding etc..(2) spray forming. When molding reinforced plastic products, a method of spraying a short cut of fibers and resins simultaneously onto a mold and solidifying them into an article by means of an airbrush is described.

- Q: What is the price of a small jujube packing machine?

- Small packaging machine is mainly divided into single grain and multi grain packaging, there are 3-6, there are about 200000. Mainly depends on the performance and use of the machine

- Q: What are the packing machines?

- They make packing equipment. There are many kinds of food packaging, sealing packaging, pillow type packaging machine. I hope I can help you.

- Q: Color code positioning of packaging machinery

- The use of the printed color packaging materials, photoelectric switch (available on the color electric eye tracking and positioning), through the control system to drive the stepper motor rotation and color according to the distance between the automatic stop, to complete and accurate packaging products logo.

- Q: Which friend is an expert in mechanical equipment or a better understanding of sealing machines? Tell me how to identify the equipment

- Take the food packaging machine for example, if only from the hardware, then you can ask when you buy the degree of automation, semi-automatic or fully automatic, the use of steel ah,

- Q: What is a packaging machine?

- Well, before and after the associated processes, such as cleaning, stacking and disassembly. In addition, the package also includes the measurement or in the processes of stamp packages. Mechanical packaging products can improve productivity, reduce labor intensity

- Q: Donkey hide gelatin cake made of sticky, forming very well, that is, vacuum packaging, after a little sticky in the vacuum bag, what's going on?

- For custom vacuum bags, I would recommend a manufacturer who has customized experience in vacuum bags because it reduces your time cost and offers a lot of advice on packaging design and customization.

- Q: Three dimensional packaging machine, transparent film packaging machine, transparent film three-dimensional packaging machine industry standards

- This standard specifies the terms and definitions, models, types and basic parameters, technical requirements, test methods, inspection rules and signs, packaging, transportation and storage requirements of the three-dimensional packaging machine for transparent film.

Send your message to us

YD-PL350E Non-stop JRT/Industrial Roll Rewinding Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords