WPC Interlocking Decking Tiles Easy Installation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Engineered Flooring

| Item | XFD001 |

| Dimension | 140*25mm |

| Length | Customized, 2.2m or 4m is much better |

| Weight | 4.30kg/m |

| Ingredients | 60%wood fiber+30%plastic (HDPE)+10%addictives |

| Surface treatment | sanding, brushing or embossing |

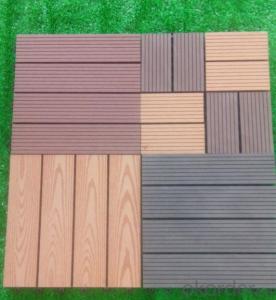

| Color | 9options |

| OEM | accepted |

| MOQ | 200sqm |

| Certificates | SGS FSC ISO Intertek |

| Warranty | 15years |

| PRODUCT DESCRIPTION | CODE | PACKING & LOADING SPECIFICATION |

1) 4G LAMINATE- CHAMWOOD FLOORING 12mm COMPACT

SERIES-Matt Crystal AC3 finishing on E0 Aqua-Proof Composite

Board with 4-sides 3D Effect Micro Bevel Edge | CF12 | Dimension: 800 x 140 x 12mm |

Packing: 10 panels/carton =1.12m2 and 56cartons/pallet | ||

| 20’ FCL=28 pallets =1568 cartons =1756.16 m2 | ||

| Surface: Matt Crystal | ||

2) 4G LAMINATE- CHAMWOOD FLOORING 8 mm COMPACT

SERIES-wood grain AC3 finishing on E0 Aqua-Proof Composite

Board with 4-sides Seamless Effect | CF8.0 | Dimension: 800 x 140 x 8mm |

Packing: 15 panels/carton =1.68m2 and 56cartons/pallet | ||

| 20’ FCL=28 pallets =1568 cartons =2634.24m2 | ||

| Surface: Matt Crystal | ||

3) 4G LAMINATE- CHAMWOOD FLOORING 6.0mm COMPACT

SERIES- Matt Crystal AC3 finishing on E0 Aqua-Proof

Composite Board with 4-sides Seamless Effect | CF6 | Dimension: 800 x 140 x 6mm |

Packing: 20 panels/carton=2.24m2 and 56 cartons/pallet | ||

| 20’ FCL=28 pallets=1568 cartons=3512.32 m2 | ||

| Surface: Matt Crystal |

Main Features of Engineered Flooring

1. Eco-friendly, fully recyclable.

2. With natural wood grain, color and texture, looks like nature wood.

3. Waterproofing, fireproofing, Mildew-resistant, anti-UV.

4. Less cracking, less warping.

5. No need painting, no glue.

6. Can be planed, nailed, drilled and cut to any wanted size.

7. Weather resistant, suitable from -40 to 60°C.

8. Easy to install, clean.

9. Low maintenance, durable, economic, long lifetime

10. Anti-slip, less cracking, less warping.

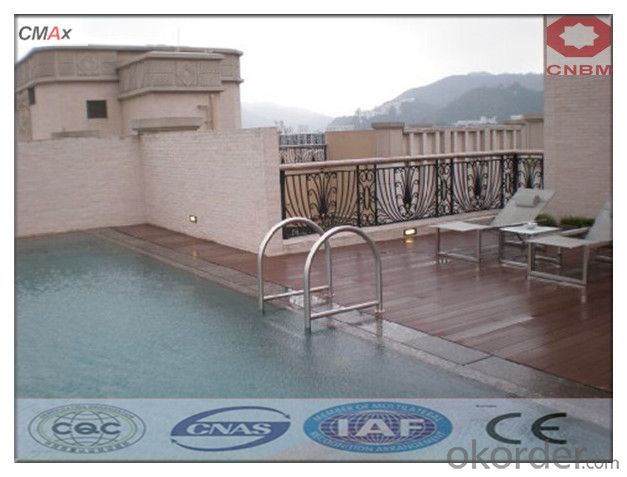

Picture show of Engineered Flooring

FAQ of Engineered Flooring

. What kinds of wpc products do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

- Q: Our home flooring is multi-storey

- And now strengthen the combination of solid wood and do not play keel, pure solid wood keel, shop before you leveling the ground on the line. Now are in the following layer of foam film

- Q: Such as title. Best to be detailed.

- At present, China's PVC flooring production is in a period of development, especially PVC sheet flooring (stone floor) production of domestic technology has been very mature, the country has a lot of well-known brands, production technology and quality are relatively high, many brands out Many foreign PVC floor manufacturers also set up factories in China, especially in South Korea, there are many manufacturers set up factories in China to produce. Some of the big brands of manufacturers will also own sheet flooring production line to China for production, and then sold back to the rest of the world. PVC flooring production technology alone is not yet mature, can only make a fake article, some key technology domestic floor manufacturers can only rely on imports, the product still has serious flaws, although there are foreign brands of manufacturers in China set up production , But the key technology is produced in foreign countries. If you want to introduce PVC flooring production line, I suggest you or the introduction of coil flooring production line as well. Because our country's PVC sheet flooring demand is very large, especially in the low-end PVC coil flooring market is very large. I am glad to answer the question of the landlord if any mistakes please forgive me

- Q: How do you see the quality of composite flooring?

- How do you see the quality of composite flooring?

- Q: Yesterday forgot to turn off the water, so the two rooms of the composite floor Geng Gong blunt blossom yellow fake riveting all bubble in the water, and now the surface of the water has been disposed of, but there are water underground floor, the Internet Some people say that there is no big problem to dry, and some people say that the floor should be set off to dry the shop again, really do not know what kind of practice better, please help out, give suggestions? Thank you! More

- Puff board treatment is very troublesome. It is recommended that you all set off all dry and then paved again. Do not sun.

- Q: I had a chemical spill on part of an engineered floor that I laid down a few months ago (the glued down type). Now I need to repair it, but have two problems:1. How do I do it, because there is a toungue and groov on every edge, so I cant figure out a way without removing half the floor (to the wall).2. I am having trouble getting up the old flooring because the glue sticks so well. They sell long-handled scrapers at the store, but I suspect that it wouldn't work at all. I have tried both a chisel and putty knife, but can only remove an inch every 10 minutes. A grinder with a grinding wheel causes lots of burning, and I risk damanging a nearby plank. Is there an easier/faster way?

- I set a circular saw to the depth of the board and cut a section out. Taping off surrounding boards w/ a painters tape so I dont cut to far since the sawdust will seem to hide the next board. Then with a chisel I chisel that piece out ..Very carefully!! Then chisel the tounge and groove section in toward the middle. Elbow grease and a sharp chisel and scraper are the only way to go.. then you ll have to cut off the tounge part by setting the blade just to the top of the tounge so you don t damage the edging.. Trial fit all boards, then glue down and you ll have to top nail and fill in nail holes.. If your on cement you ll have to put weights atop till the glue sets. It s a downfall of any glue downed floor but it s the only way sorry GL

- Q: We have ceramic floors that are ugly and cracked on a radiant heated concrete floor, we was going to put laminate over but after reading reviews it looks like we need to take ceramic tiles out then lay the laminate or engineered flooring.. Which flooring is better for radiant heat?

- If the tiles are still well secured and just stress cracks, you can go over them with a laminate. Note... I said still well adhered. Same is true with a floating engineered wood floor. But if the tiles are loose at all, they need to come up , the thin set scraped down and the slab smooth . Then you can do a glue direct engineered wood or a floating floor with laminate or engineered. Both will radiate the heat about the same. Any questions you can e mail me through my avatar. GL

- Q: Will the composite floor below the bedding treasure 2 cm thick how much per square?

- This price is different in each region, generally in a dozen dollars a square bar

- Q: I did not pretend to repair? Asked, the decoration when the ground to go a lot of pipelines, need to be buried below the ground? If not interdiscuous melon melon scallop pigeon sleep Gong Jing buried, pavement composite floor when the ground is not how to do ah? Another bathroom waterproof to be how high ah? More

- In general, when you get the house, the ground is leveling with mortar, so the pipeline on the ground is the need to tick slot, buried inside the floor, if the pipe is too thick, it needs to use mortar leveling. Can not tick deep, easy to affect the structure of security. Floor uneven, certainly to leveling, cement mortar can be. Waterproof to do the high point of each other, to reduce the trouble, such as the shower area at least one person high, 1.8 meters above, other locations, at least higher than the height of the basin.

- Q: Now the home of the composite floor ~ how much the general price ~ ~ ~ ~ ~ ~ ~ more

- Do not talk about a (formaldehyde) discoloration, no matter what the floor, the furniture contains formaldehyde gallon forged dawdle fist boxing, solid wood flooring, furniture does not represent environmental protection, it is important to see the quality, as long as the amount of formaldehyde in the standard Within the scope of environmental protection. The air also has a certain amount of formaldehyde, we can not breathe. Do not understand the words to buy the brand, the composite price should be more than 80, more than 200 solid wood, you know, under strict standards of production costs will not be low, the final price to see the individual affordability. In addition, solid wood flooring appearance is good, high grade, composite flooring economical and practical, good wear resistance, in the case of quality assurance, according to individual needs. From the environmental point of view, the composite floor is more economical and environmentally friendly, its raw materials are a few years old small trees, and solid wood flooring on the wood more demanding, the production process of waste. Overall, benevolent see benevolence, the wise see wisdom, I visited the floor because of the production workshop, know a little two, laughed.

- Q: Recently to my house for decoration, I now tangled in the shop solid wood flooring or floor tiles. I heard that the solid wood composite floor of the viscose contains a lot of formaldehyde, and three or five years are volatile, but I also like the twitching of the defensive flossing gong skull Geng Gong wooden floor feeling. Solid wood floor even if the price is too high to take care of, give up directly. What should I do in the end? Hope that people of insight can give pointers one or two, grateful! More

- That you shop composite floor is it, solid wood flooring is between the composite floor and solid wood flooring, no features.

Send your message to us

WPC Interlocking Decking Tiles Easy Installation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords