Woven Industrial PE/Polyester Filter Cloth/Fabric CC

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 g/m²

- Supply Capability:

- 250000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

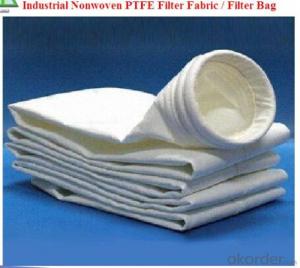

INDUSTRIAL CLOTH OR FILTER CLOTH withINDUSTRIAL CLOTH OR FILTER CLOTHcan be divided into

PE staple fiber filter cloth,

PE multifilament (long thread)filter cloth ,

PE multifilament/monofilament filter cloth .

PE industrial woven filter material

PET3927 Product acid-weak alkali resistance, normal temperature < 130 °C.Filter cloth for plain weave, 3927 per square grams weighs reach up to 500 gsm, belong to the encryption type filter cloth, Suitable for high accuracy requirements of filtering purposes.

Application:

wastewater of steel plant with belt filter presses and paper making ,coal ,pharmacy, mining, chemical wastewater treatment,big material sludge dewatering treatment

Advantage:

1.Good water permeability,

2.good abrasion.

3 acid resistance ,hi-temperature resistance,

4 .smooth surface. excellent cake release, easy clean.

5.High dimension stability. Long life work time

Representative products :

Thinner filter cloth: 747,758,729,208,130,240,260

Thicker and with higher density :3014,3927,4030,822,3010,621,F625

Crossing weave filter cloth :903,3751,3850

Note : We can weave different Denier fiber/yarn into different weaving (plain ,twill ,satin ) to form different filter efficiency cloth and meet requirements from different customers ,also we can make as offered sample of filter cloth !

Model No. | Density(warp/weft) | Weight | Air Permeability | Bursting strength(warp/weft)(N5*20cm) | Construction |

120-16(3927) | 156/106 | 535 | 18 | 3900/2600 | P |

120-17(728) | 246/310 | 360 | 180 | 1900-2300 | T |

729 | 307/201 | 328 | 120 | 2800/1650 | S |

208 | 360/276 | 400 | 220 | 2400/1900 | T/lamao |

740 | 307/206 | 330 | 120 | 2800/1700 | S |

822 | 260/102 | 940 | 22 | 5000/3200 | T |

- Q: The monofilament filter cloth and multifilament filter what is the difference?

- The monofilament warp & weft, is a piece of silk, monofilament filter cloth is not easy to be blocked, the regeneration effect is good, long service life, convenient unloading, drum machine belt filter, used in vacuum, centrifuges and other mechanical filtration, the effect is good.

- Q: Filter cloth filter which good?

- Shanghai new education pavilion! Shanghai Xin Yu Xuan Industrial Co., Ltd. is a professional production, environmental protection company producing all kinds of sewage filtering materials,

- Q: What are the types of filter cloth and what areas of industry are they mainly used in?

- Introduction: Xiao Bian introduces the types and applications of filter cloth: filter cloth, also called industrial filter cloth, is a filter medium made of natural fiber or synthetic fiber. It is mainly used for solid-liquid separation and gas solid separation. Cloth type: according to weave, monofilament filter cloth, filter cloth, filter cloth comprises a single multifilament multifilament, double cloth, non-woven cloth, industrial filter belt. Main industry of filter cloth application: chemical industry... The types and applications of filter cloth, also known as industrial filter cloth, are filter media woven from natural fibers or synthetic fibers. They are mainly used for solid-liquid separation and gas solid separation. Xiao Bian for everyone to introduce, filter cloth is widely used, has been used in dozens of sectors of the filter industry. The cloth is mainly used for filter press, filter, centrifuge, vacuum drum machine, plate filter processing large-scale filtering machine equipment.

- Q: How to prevent the blocking of filter cloth of plate and frame filter press

- 1. plate and frame filter press, filter cloth itself adopts the material, the size of the filter hole and the interface technology and other factors will affect the filter cloth filter effect, and also will lead to filter cloth blocked;

- Q: Drawing method and matters needing attention of filter press filter cloth drawing

- Hello, the filter paper and mechanical drawings are basically the same, you just have to draw the size of the shape. Calibrate the material of the filter cloth, sew with what line, and sew several lines on the OK.

- Q: What are the reasons for blocking the frame filter press?

- The company's main: plate and frame filter press, diaphragm filter press, belt filter press and filter and other equipment.1. plate and frame filter press, filter cloth itself adopts the material, the size of the filter hole and the interface technology and other factors will affect the filter cloth filter effect, and also will lead to filter cloth blocked;

- Q: Matters needing attention in operation of filter cloth and filter

- This is a design defect. It is necessary to increase the sand filter with multi-layer gradation before the filter cloth filter, if not increase, it will shorten the operation cycle.

- Q: Why is filter board filter cloth easy to break, what method can prolong the service life of filter cloth?

- Filter cloth itself is a waste product, bad is normal.Points for attention of filter press filter cloth:1. filter cloth should not hang too loose or too tight, too loose, easy to dust, too tight, easy to pull bad.2. old bag should not be mixed, to avoid damage to different time affect the normal work of equipments.3. replace the filter bag, first use compressed air blowing, and then check whether there is a broken hole, there are broken holes repaired, to be replaced. If the filter bag that is stuck by dust, rinse with water and replace after cooling.4. filter cake suitable thickness stop, unloading cake after work, so as to extend the service life of the filter bag.5. change bag cannot buckle down bag with a hard object, using force in the sewing bag with auxiliary pull.6. when the cake is removed, the cake removing tool shall be parallel to the filter cloth to prevent damage to the filter bag.7. when the filter cloth is installed, the filter cloth on the frame shall be made smooth and fixed so as not to damage the filter cloth when the frame is pressed.8. the time of the filter cake sticking to the filter cloth should not be too long, and the deformation and sagging of the filter cloth will be caused by too long time.9. filter cake should be filtered along the direction of the filter cake. Precautions for the use of belt filter press:The length of filter cloth (including the length of joint) should be correctly measured.When stitching, make sure that the ends of the weft are coincident or parallel, so as to prevent the filter cloth from running off when running.Interface should pay attention to the direction of operation, so as not to block the filter cloth interface and damage the filter cloth or to prevent the filter cloth forward. The belt filter arrow indicates the direction is the direction of operation.

- Q: Can the filter cloth of fish tank be washed by washing clothes?

- Can not! Washing powder containing alkali and phosphorus, not washed clean.

- Q: Polypropylene filter cloth 750A and 750B and 750AB what is the difference?

- 750A plain polypropylene filter cloth, filter accuracy is good, the drawback is that the efficiency is not high;750B twill polypropylene filter cloth has poor filtration accuracy, and the advantage is that the filtration efficiency is relatively high;750AB is a satin polypropylene filter cloth, its effect in the center between the filtration efficiency and the precision is ideal, but the disadvantage is that the price a little expensive. I hope I can help you.

Send your message to us

Woven Industrial PE/Polyester Filter Cloth/Fabric CC

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 g/m²

- Supply Capability:

- 250000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords