Needle Felt with Good Price with Industrial Cloth or Filter Cloth

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 g/m²

- Supply Capability:

- 250000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Liquid Filter Bags/Vision Filter Cloth/Needle Felt

INDUSTRIAL CLOTH OR FILTER CLOTH withINDUSTRIAL CLOTH OR FILTER CLOTH

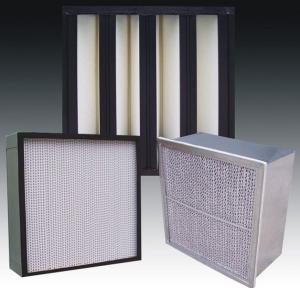

These bags are widely used in such industries as food and beverag,bioengineering and pharmaceutical,automobile manufacturing,petroleum and natural gas,electronics and galvanization,coat,paint and ink,nuclear/thermal power plant and waste liquid filtration,fluid filtration in photographic film production process,fluid and gas purification in daily chemicals industry,filtration of various fluids in textile,printing & dyeing and paper making industries.

Materials used for liquid filter bag collars:stainless steel collars.galvanized steel collars and Ppplastic collars.

Precision:1、5、10、15、25、50、75、100、150、200

Sizes: | IN | CM |

Size1 | 7×16 | 17.8×40.65 |

Size2 | 7×32 | 17.8×81.3 |

Size3 | 4×8.25 | 10.2×20.9 |

Size4 | 4×14 | 10.2×35.5 |

vision Filter cloth is mainly used in liquid/solid separation and dust collection.

It’s commonly used in smelling works, chemical plants, sugar refining, dyestuff industry, pharmacy, food industry etc.

Not only the abrasion, but the erosion from filtrate will affect the service life of filter cloth. The following specialties are requested for the industrial filter fabric.

A. Great solid particles arresting efficiency and long service lift.

B. Higher and more stable filtration velocity, less clopping up possibility than conventional.

C. Filter cake can be easily released. The fabric is with great dimension stability and non-flexibl

- Q: The monofilament filter cloth and multifilament filter what is the difference?

- The better discharge). But in many chemical industry, for the material to filter the small particles, monofilament filter cloth can not meet, so the cloth or multifilament widely used. Currently imported cloth in the filtration accuracy, service life, regeneration, discharge Shape, resistance, acid and alkali are better than homemade cloth. The above is for reference only. Welcome to exchange

- Q: What are the types of filter cloth and what areas of industry are they mainly used in?

- Introduction: Xiao Bian introduces the types and applications of filter cloth: filter cloth, also called industrial filter cloth, is a filter medium made of natural fiber or synthetic fiber. It is mainly used for solid-liquid separation and gas solid separation. Cloth type: according to weave, monofilament filter cloth, filter cloth, filter cloth comprises a single multifilament multifilament, double cloth, non-woven cloth, industrial filter belt. Main industry of filter cloth application: chemical industry... The types and applications of filter cloth, also known as industrial filter cloth, are filter media woven from natural fibers or synthetic fibers. They are mainly used for solid-liquid separation and gas solid separation. Xiao Bian for everyone to introduce, filter cloth is widely used, has been used in dozens of sectors of the filter industry. The cloth is mainly used for filter press, filter, centrifuge, vacuum drum machine, plate filter processing large-scale filtering machine equipment.

- Q: Why do cleaning filter cloth with caustic soda

- What detergent to use for cleaning filter cloth depends on the kind of filter medium. But it is not commonly used in caustic soda.When the filter cloth is used for a long time, water permeability will decrease. Effect of permeability, the water is often encounter. Generally after rough washing, and then placed in dilute acid immersion, and finally rinse with water.

- Q: How to prevent the blocking of filter cloth of plate and frame filter press

- 2. polyester materials, this material is generally applicable to acidic filtration, but also high temperature resistance, tensile resistance, vertical and horizontal stability, wear resistance second only to nylonThis is the most widely used filter cloth on the market at present;

- Q: Power plant desulfurization vacuum belt filter cloth filter cloth interface total open what is good

- The gypsum slurry cyclone to hit through the pump, the centrifugal force was graded in the cyclone underflow, containing larger particles, high concentration of underflow by height difference in the cloth fell on the vacuum belt machine.

- Q: How does the thickness of filter cloth affect the dust removal process?

- ncy decreased more rapidly, but the cloth is too thin to low mechanical strength, short service life, the dust removal efficiency is not high.

- Q: What's the difference between filter cloth and filter screen and filter cotton?

- The filtration degree is different, the filter screen, filter cloth and filter cotton are gradually precise

- Q: How are the types of filter cloth distinguished? Filter cloth and dust cloth is not a kind of ah, thank you

- According to the filter cloth in the use of filter to distinguish: belt filter cloth, plate and frame filter cloth, centrifuge filter bag and so onAccording to the material to distinguish: filament filter cloth, monofilament filter cloth, tear film, filter cloth and so onSatisfaction, please adopt.

- Q: How to deal with the filter cloth for a long time?

- 5 cleaning process of filter cloth:A, two step cleaning procedures: hot water cleaning (80, 10 minutes), clean water.B, the three step cleaning procedure: rinse (5 minutes), 2 + 0.3% liquid immersion (75 + 5 C, 1 hours), Shimizu Shirai (pH water washing to neutral, pH test paper).C, the five step cleaning procedure: Shimizu Shirai (5 minutes), 1.5 + 0.3% hydrochloric acid (65 + 5 C, 1 hours), wash (5 minutes), 2 + 0.3% liquid immersion (75 + 5 C, 1 hours), clean water (water washing to neutral pH, pH test paper).6, filter cloth cleaning frequency: continuous production of each batch of two step cleaning cloth; the continuous use of one month and two months for cleaning cloth three steps; three months, four months and five months of continuous use of five steps of cleaning cloth.7, filter cleaning, the last wash must be washed to the water, pH near neutral.

- Q: What filter cloth does the filter press use for coating waste?

- At present, the common filter cloth is made of polymer polypropylene filter cloth, also known as PP filter cloth.Of course, it can also be made of nylon or other polymer materials.

Send your message to us

Needle Felt with Good Price with Industrial Cloth or Filter Cloth

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 g/m²

- Supply Capability:

- 250000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches