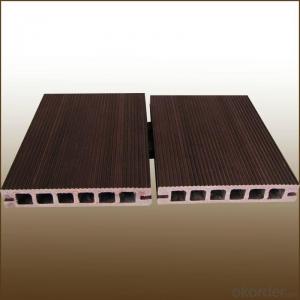

WOOD PLASTIC COMPOSITE, high quality rosewood co extruded wpc decking

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Main Features of the WPC Decking:

1. Recyclable, Eco-friendly, saving forest resources

2. With the look of the natural wood, but less timber problems

3. Moisture/water resistant, less rotten, proven under salt water condition

4. Barefoot friendly, anti-slip, less cracking, less warping

5. Requires no painting, no glue, low maintenance effort

6. Weather resistant, suitable from minus - 40 to 60 centigrade degree

7. Termites and insects resistant, and moldy-proof

8. Easy to install and clean

Specification of the WPC Decking:

component | 30%HDPE(Grade A Recycled HDPE) 60%bamboo/wood fiber component 10%chemical additives New material capped outside |

Size | 140X20mm |

Design | Solid decking |

Length | 2.9m/pc standard length, also from your required |

Surface treament | original, sanded, brushed |

Color available | 5 regular colors for choice ( IPE,Walnut,graystone,Cedar,Rosewood) and we can adjust the new color according to the order requirement |

Cerfiticate | ISO9001, ISO14001, CE, FSC Certificate,"REACH"Test Reports by SGS; Intertek Test Report by ASTM standard..etc. |

Images of Co-extrusion WPC Decking:

FAQ of Co-extrusion WPC Decking :

1. Available Colours?

5 regular colors to choose ( IPE,Walnut,graystone,Cedar,Rosewood )

2. How to Install?

3.Treatment for Option

- Q: Benefits and effects of composite flooring? Do you buy more people?

- Not easy to deformation, inexpensive, beautiful.

- Q: Composite floor water from the package how to deal with

- First of all, the first time of course, to the water on the floor quickly dry, to prevent the spread of water. Can also take the water in the water floor of the splash gap in the water sucked away the water vapor, or take the dryer with cold air dry. Second, if the water after the floor so that a small area of ??the seams from the Alice, you can use heavy pressure to pressure in the above, after a period of time after the wooden floor will return to normal. If after a period of time, the seam was drums down, but with the floor before the difference is too far, you can try to wax the floor, waxing after the bubble floor will be almost the same as the original. If the wax after the color of the floor, the shape and the original or a great difference, it is only partial replacement of the floor. Again, if there is a large area of ??the phenomenon of soaking water, should be promptly to inform the floor after-sales service. If it is solid wood flooring, as far as possible to keep the floor is not deformed in the case of the floor carefully pry up, according to the well-type superposition placed in the ventilation at the dry, with its weight produced by the deformation to prevent the occurrence of deformation, under normal circumstances for the quality Good solid wood flooring can be used again. If it is to strengthen the wood floor, quickly remove the floor of the baseboard, exposing the expansion joints, by the expansion of the water vapor will be distributed, according to the size of different seepage, dry up usually takes about three to ten days, generally strengthen the large area of ??wood flooring bubble The water is likely to be used again.

- Q: How is the elephant parquet?

- The elephant solid wood flooring is very good ah, in the solid wood flooring industry, the image of the brand is still very advantageous, but the price of fines and reincarnation of the old group is more expensive, buy or according to individual economic conditions The If you need cost-effective, then you can consider the next Linchang floor, Kenya Asia, peace of mind, Chunzhou Oude, Hao Ge these are also quite good, you can go to contrast. China's top ten brands to buy the top of the top ten solid wood flooring brand list, there is time to go there to see the query Oh

- Q: Is the composite floor fading away?

- Just do not fade away, but it will fade for a long time. Strengthen the composite floor is in the wood after crushing, adding preservatives, additives, hot press after high temperature and high pressure suppression treatment, so it broke the physical structure of the logs, to overcome the poor stability of the logs. Composite floor of the high strength, uniform specifications, high wear resistance, corrosion, moth. Strengthen the floor also need to maintain, but relatively speaking, is still relatively easy, usually with no dripping mop to drag it. The composite flooring is fitted with a lock, which is easy to install or remove. If you want to use the floor again when you move, you can easily remove it. Solid wood flooring surface is made of natural wood, no deformation, no cracking, pavement simple, surface wear resistance and anti-slip flame retardant performance. Theoretical Description: Solid wood flooring is divided into three layers of solid wood flooring, multi-layer parquet, the new solid wood flooring three, because it is made of different types of plate staggered laminated, thus overcoming the solid wood floor unidirectional Shortcomings, dry shrinkage expansion rate is small, with good dimensional stability, and retain the solid wood flooring natural wood and comfortable foot feeling.

- Q: To buy a composite wood flooring, selected a Ruijia light, came back to listen to friends that light is not good, easy to scratches and fade; others say that the light is not the piano light, there will be no fade and wear Open swine swallowed the state of sand and pepper. I can not get it anyway. Please understand the advice of friends, thank you! More

- A variety of colors of paint or paint are matt and light of the points, matte surface a little hairy, like the surface of the same glass. Reflected light is "diffuse reflection", no glare, not assassination eye, giving a sense of steady and elegant. Bright light is the surface smooth, reflective light mirror reflection, glare. Giving a bright and gorgeous feeling. It is only through the matte and light to distinguish, but personal preferences, as well as matte floor and bright floor use of different lighting room, the choice of different floors, in principle, the use of different parts of the floor, Is a good use of matte floor lighting, and vice versa use light, of course, is not absolute.

- Q: What you mean by Engineered flooring? What is the benificts of Engineered flooring?

- Engineered wood is an all wood product made of several plys of wood criss crossed for strength just as ply wood is. Its usually made of three plys but I ve seen cheaper stuff with as many as 5 plys. Its a thinner wood ( 3/8ths inch thick on average but you can get thinner and thicker) It s made for places where thickness is an issue and you can t use the standard 3/4 solid wood. Its more versatile in installation . than standard wood. Its made to be glued, nailed ( stapled actually) and made to float in special applications. In certain applications it can be used below grade ( certain applications mind you) . The wood is made to strict milling so it goes together easy and is very DIY er friendly. Any questions you can e mail me through my avatar. GL

- Q: Thank you for helping me? There is the price

- Solid wood flooring is made of wood, and composite flooring is generally done with the MDF, the two are fundamentally different, mainly to see its side, a look to know

- Q: What is the difference between he and solid wood flooring?

- Composite flooring is one of the flooring. But the composite floor was artificially changed the natural structure of the floor material, to achieve a physical performance in line with the requirements of the floor. Composite flooring in the market often refers to strengthen the composite wood flooring, solid wood flooring. However, the term composite flooring does not exist in terms of technical terms and national industry standards. Floor, ie the surface of the building floor or floor. Made of wood or other material. Composite flooring is one of the flooring. But the composite floor was artificially changed the natural structure of the floor material, to achieve a physical performance in line with the requirements of the floor. The general classification of the floor is: According to the structure classification: natural landscape feng shui floor, solid wood flooring, laminate flooring, solid wood flooring, bamboo flooring, cork flooring, etc .; according to the use of classification: home floor, Anti-static floor, outdoor flooring, stage dance dedicated floor, sports hall dedicated floor, track and field dedicated floor; according to environmental protection classification: E1 grade floor, E0 floor, JAS star environmental standards F4 star floor and so on.

- Q: Composite flooring installation requires tools,

- Wooden floor installation requires the following tools: Power tools: hammer, pistol drill, marble sawing machine, curve saws, steam pump, steam gun, electric planer, mill, belt sander. Hand tools: hand saws, knife saws, fountains, steel tape, angle ruler, pencil, pull rope, hammer, ax, rubber hammer, punch, scraper, screwdriver, pliers, flat chisel, planing, Special tools: move the hook, tighten the hook. Wood flooring installation process should pay attention to: 1, wood flooring can not buy that shop, should be opened in the new home after a period of time and then shop, so that the wooden floor to adapt to the new environment. 2, do not think that the wood floor can not contain water, in fact, left the water, the wood floor becomes very hard, at the foot of the feeling is not the same, so to keep the wood floor water content of about 14%, of course, this is a professional tool inspection of. 3, wood grille and the ground between the grass-roots should retain a certain gap (primary school textbooks to teach us, to know how to stay a seam), to ensure that the entire ground dragon air patency, do not use cement mortar plug to fix the wood grid In order to use the mattress method, the wooden grille shall be firmly fixed to the ground with nails. 4, shop wood flooring should be cleaned before the wooden grille, sprinkle with moisture-proof powder and pest control powder. This is to prevent insects from eroding the wood flooring material and destroying the structure of the wood floor. 5, nail wood floor nails must use twist nails, first in the mouth of the mouth oblique drilling (holes should be perpendicular to the length of the floor), and then into the wooden grille, or the use of the process is likely to cause loose wood flooring. 6, after the laying of wood flooring to use cardboard, old sheets or old mats and other cover protection. The purpose of this is to protect the original installation of the wood floor structure, firm its structure.

- Q: Has anyone worked with Bostik EFA for installing an engineered floor? Is EFA better than Bostik Best?

- Bostik Best is the premium adhesive in the wood flooring industry, also the most expensive. You should look at Mapei 980, or Taylor MS Plus adhesives for a lower cost option.

Send your message to us

WOOD PLASTIC COMPOSITE, high quality rosewood co extruded wpc decking

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords