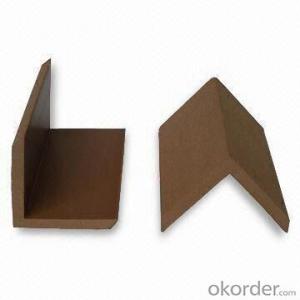

Wood Plastic Composite Accessories clips

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 PCS

- Supply Capability:

- 2000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

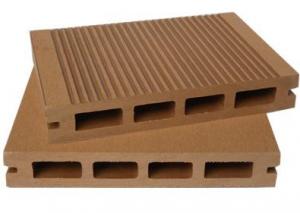

Forestar WPC offers WPC decking with outstanding quality, best service and competitive price.

FORESTAR WPC ACCESSORIES

FEATURES AND ADVANTAGES:

Outstanding Characters

• Dimension stability

It will not be out of shape after a long testing of 10 years and there is no crack under the test temperature between -40°c to 60°c

• Material Safety

Low flame spread / High slip resistance / No sting of wood / Contains no toxic chemicals or preservatives / Environmental friendly / Can be recycled with 100%

• High Strength

Outstanding screw and nail retention / High impact resistance / Great Compressive-tensile-shear strength / Modulus of elasticity: 20% greater than PVC

• Good appearance & nice touch

Natural feel & wood touch / Broad range of finishes and appearance, Multicolor, and needn't to painting

• Longevity

Its lifespan at least 10-15 years in the outdoor weather condition

• Install & Maintain easily

Easy to produce and easily fabricate / Easy to cut, fix and glue; Easy to tenon, drill and nail / Require less routine maintenance / No need staining & water Sealant

Competitive Price

• Using most advanced machinery to increase the output and reduce the costs.

Strong technical support from famous institute of high polymer to guarantee the best quality as well as cost saving.

• Neighboring one of the biggest wood/ bamboo processing industry region and having a special purchase channel of the raw materials (Plastic and wood/bamboo fiber)

• As a high technology and environmental-friendly enterprise, supports form the government such as reduction and exemption of tax rate are available.

INGREDIENT Forestar WPC products are made of:

• 60% Bamboo/wood powder

• 28% Recycled HDPE/PP/PE/PVC powder

• 12% Chemical additives such as colorants, coupling agentsstabilizers, sreinforcing agents, foaming agents, lubricants, anti-UV agent, Anti-oxidation agent and anti fungus agent.

component of chemical additives may alter a little from different products adapting to different physical/ chemical demands.

FORESTAR'S BELIEF

In manufacturing products made entirely from waste plastics and waste wood, we have demonstrated our commitment to a number of crucial objectives.

• To ensure our products always exceed expectations of the purposes for which they are intended. To create products that are much more endurable than those made from conventional material.

• To constantly improve our technology to ensure the maximum amount of waste can be recycled.

• To minimize wastage in our manufacturing processes.

• To conserve precious natural resources.

• To provide customers the option of a new and update products, rather than something our previous customers asked for.

- Q: Can the bathroom PVC plastic floor?

- The bathroom (bathroom) is not only a toilet, but the toilet, toilet, bath collectively. According to the layout of the bathroom can be divided into independent, dual and eclectic type three.

- Q: PVC plastic floor construction costs a square meter

- 10-35 yuan with the tape [interface agent to glue the self leveling,] the specific price to see the construction site set

- Q: The new rent a house, rough housing, house, do not want to decoration, but the cement really ugly, but the old feeling clean and fresh, a plastic carpet, feel the taste, said that before reading not made of plastic cloth, do not know whether to shop on the ground is also very harmful to me? Want to know now: plastic carpet and cement that is more harmful to human body?

- (4) heavy household level or general professional grade: for severe wear at home;(5) severe professional use level: the family generally do not use;(6) luxury: the quality of the carpet is good, the fiber is long, so luxurious style.

- Q: The home is all ceramic tile or plastic floor

- Unwanted。 In winter, you can carpet in the bedroom. I hope my answer can help you

- Q: What is the difference between plastic floor and floor leather? What is the wear resistance of plastic floor? How to distinguish the quality of plastic flooring?

- Floor leather lifeIn fact, it is necessary to maintain the long-term beauty of the floor leather, routine maintenance and maintenance is also very important. First of all to keep the floor clean, no sand, dust, dirt on the floor surface friction; timely addition to the net, don't use acetone, cyclohexanone, concentrated salt water and other organic solvents scrub, to prevent surface color fade, degumming, cracking or warping, available detergent or detergent to clean. Weekdays with semi dry mop to clean up, to prevent water from seeping through the seam, bond failure. In this way, the floor leather is very durable

- Q: What is the role of the floor mat plastic sheeting

- Mainly moisture-proof insulation, to protect the wooden floor

- Q: Domestic anti - slip plastic floor leather with moisture-proof effect

- 1, commercial floor material PVC (real name: PVC floor)2, commercial floor PVC wood material3, commercial floor uses: kindergarten, office, stairs, family, factories, schools, hotels, hotels, KTV, bars, massage parlors, beauty salons (shops), clothing stores

- Q: What is the plastic floor, what is the plastic floor

- Plastic floor according to its material can be divided into hard, semi hard and soft (elastic) three. The floor is soft roll, hard floor for bulk. In twentieth Century, China mainly produces semi hard flooring, foreign production of elastic floor.

- Q: Household PVC anti-static plastic floor

- PVC particle interface between the formation of conductive electrostatic network, with permanent anti-static function.

- Q: Our hostel is covered with plastic foam, so it's hot now

- Foam pad a quilt on a mat mat effect is very good

Send your message to us

Wood Plastic Composite Accessories clips

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 PCS

- Supply Capability:

- 2000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords