WDS Low Conductivity Microporous Insulation Board Temperature Reduction from 950 to 240℃

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4480 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Microporous Insulation Board:

CMDS Microporous Insulation Board is specially designed for steel industry & metallurgy with very good thermal and mechanical properties. The formulation is an opacified blend of filament reinforced pyrogenic silica. The coverings is water repellent to assure the stability of the microporous board when moisture may occur due to castables, mortar etc.

2.Main features of Microporous Insulation Board:

◆ Extremely low thermal conductivity ◆High compressive strength

◆ High thermal stability ◆Environment protection

◆ Easy to handle ◆No harmful inhalable fibers

◆ Resist most chemical attacks ◆Free of organic binders

◆ Non combustible

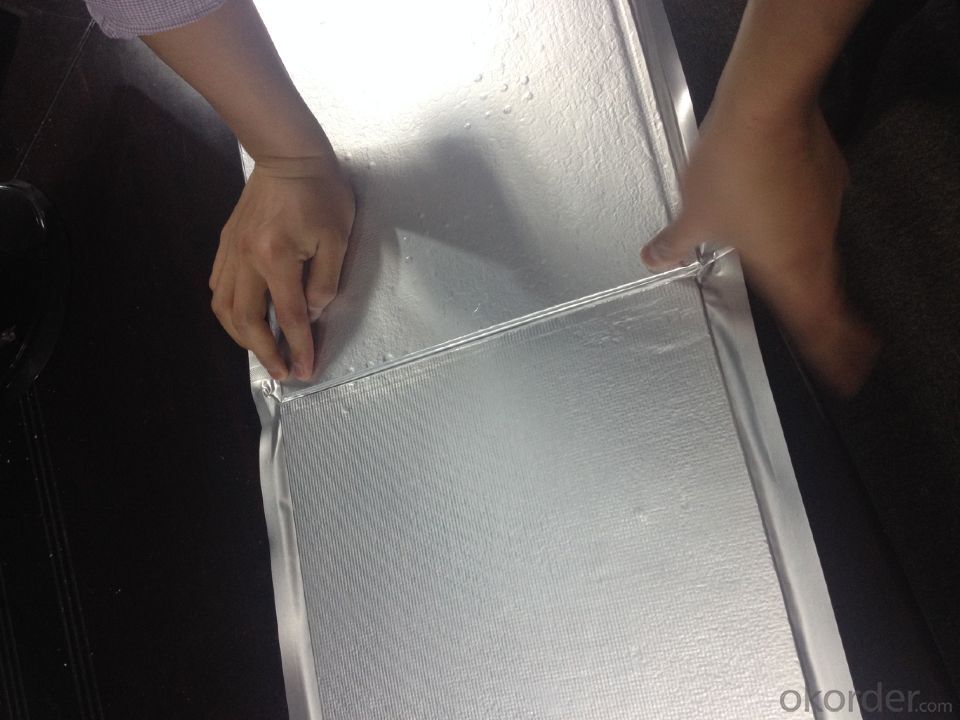

3. Microporous Insulation Board Images:

4. Microporous Insulation Board Technical Parameters

CMDS Microporous Insulation Board can be shaped easily with a simple cutter and taped off with aluminum tape. The board can be fixed in place with the same adhensives that are used for refractory lining.

Application: Ladle, Torpedo Ladle, EAF, Degassers, Cement Rotary Kiln, Ceramic Firing Klin, Aluminum Melting and Holding Furnace and so on. If you need other application picture, please contact with us

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about our board?

A world class manufacturer & supplier of Microporous Insulation Board is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Can acrylic materials be perforated? How to do waterproof after punching?

- Or in the back with glass adhesive paste anti-corrosion nine PCT board (if the hole is flat, Anti-corrosion nine PCT is to remove the other side of the paste surface with asphalt anti-corrosion paint brush)

- Q: Find the construction steps for waterproof coatings

- 1, base surface treatment (1) roof structure After the completion of concrete pouring, should be repeated water compaction, so that the surface of the grass-roots level, the flatness with 2m to check the ruler, ruler and grass-roots gap of not more than 5 mm, and only allow gentle changes. (2) the base surface of the pores, rugged, honeycomb, gap, sand, etc., should be promptly treated, the base surface must be clean, no floating slurry, no water beads, no water; when the base surface appears more than 0.3 mm cracks , Should rush each 10 cm brushing 1 mm thick polyurethane coating waterproof layer, and then set the polyurethane cloth reinforcement layer, and finally brushing waterproof layer. (3) all the corners are used 5 × 5㎝ 1: 2.5 cement mortar for chamfering, the angle made R = 10 mm rounded corners.

- Q: What material is used for waterproofing of tarpaulin

- Regardless of the construction or finished products are toxic, due to organic materials, it will form a separation layer, partition structure of poor wear resistance, must be a protective layer of solid, not hollowing, but requires the base surface moisture content of less than 8% overlap requirements No interface to form a seamless body thickness control easy to control the local thickness difficult to control

- Q: Cabinet is to buy finished products, or directly to the decoration company to do?

- My home decoration cabinets are Haotian decorative package to do, although expensive, but still very worthwhile, all of their wood will be waterproof and moisture, in contact with the wall will do the underground waterproof and moisture, and are on-site cash Now do, timber materials can be seen directly, the amount of glue is not much, less formaldehyde, the latter part of the living is also more comfortable!

- Q: Roof membrane waterproof construction process, what should be noted that?

- Four do not: 1 surface can not afford sand 2 surface can not afford skin 3 surface is not crisp 4 does not crack

- Q: Can Henkel have water against him?

- In order to ensure the quality of the proposed do not add water, the general finished materials are proportional, emulsion and powder, in strict proportion.

- Q: FRP finished brush on what can be waterproof do not fade

- FRP appearance is the use of gel coat, we do the appearance of glass steel yacht are gel coat, also known as plastic shell, resin gel coat, etc., the color can be customized in the factory, Nanjing DSM company there.

- Q: I would like to ask how to do in the warm water above,

- Do nothing to use, because the biggest leak to the hidden danger is to warm the water, but your waterproof design does not include the warm water, you say your waterproof layer construction, in the end how much significance. It is recommended to make the waterproof floor to warm the following, as to what kind of good is not good to say that good things, that kind of good is good.

- Q: Developers have done waterproof, decoration house also have to do it

- Secondly, before the waterproof layer may be done in the house decoration, paving tiles or other equipment when the installation was destroyed, so that the waterproof layer is no longer a whole,

- Q: What is the difference between finished mortar and cement mortar?

- Finished mortar white lime compounds, and cement mortar dark gray black.

Send your message to us

WDS Low Conductivity Microporous Insulation Board Temperature Reduction from 950 to 240℃

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4480 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords