User-Friendly PPR Plastic Underground Water Pipe Fittings Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

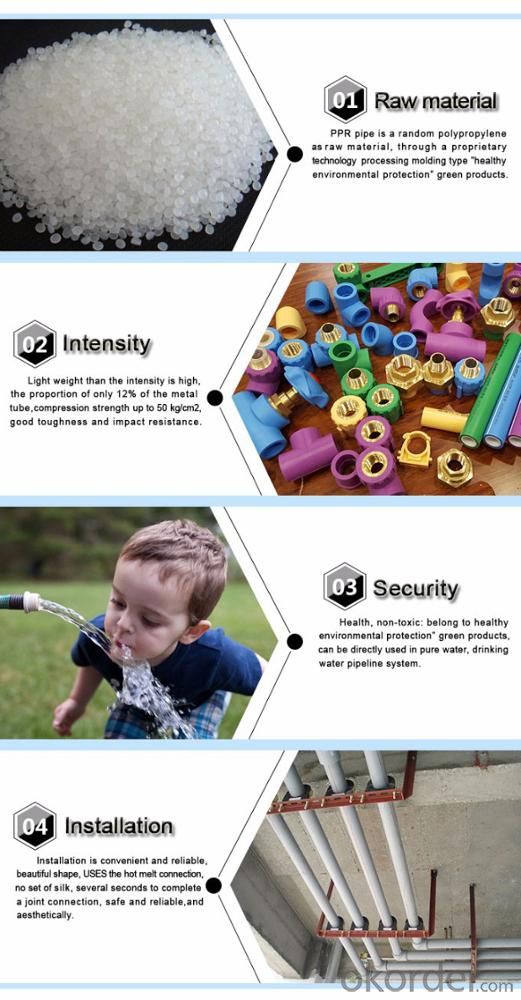

Product Overview

1) Cold / hot water supply facilities for public buildings

2) Food, chemical, electronic industry pipeline networks; Such as Pipeline networks for transporting all kinds of corrosive liquids

3) Drinking water production system pipeline networks; Such as Pure water and mineral water

4) Air conditioning facility pipelines

5) Compressed gas pipeline networks for industry

6) Pipeline networks for swimming pools

7) Pipeline networks for solar energy facilities

8) Agriculture and garden production transporting systems

Application

Distribution for cool and hot water;

Duct for drinkable water system;

Pipes for kinds of high-temperature and low-temperature heating system;

Pipes for heating and cooling settings in solar energy system;

Connecting pipe for air conditioners

Product Description

Pressure | Size(mm) | Pressure | Size(mm) |

PN1.25MPA | 20*2.0 |

PN1.6MPA | 20*2.3 |

32*2.9 | 32*3.6 | ||

40*3.7 | 40*4.5 | ||

50*4.6 | 50*5.6 | ||

90*8.2 | 90*10.1 | ||

110*10.0 | 110*12.3 |

Shipment/Payment

Packing: 5.8m/11.8m each piece. 50m/100m/150m/200m for small sizes pipes.

Loading port: China port(Chongqing port, Shanghai port, Tianjin port)

Price term we offer: FOB,CIF,CFR

Payment: L/C and T/T

Product Show

Our Services

Pre-Sales Service

1. Inquiry and consulting support.

2. Sample testing support.

After-Sales Service

1. Training how to instal the machine, training how to use the machine.

2. Engineers available to service machinery overseas.

FAQ

Q1.Where is your company, factory or trader?

A1.We are Integration of industry and trade which is located in Liaoning Province. China.

Q2.How long is your delivery time ?

A2.Generally it is 5-10 days if the goods are in stock. or it is 20-30 days if the goods are not in stock, it is according to quantity.

Q3. Can I get free samples?

A3: Yes, we can provide you the free samples, but you need to bear their own delivery costs.

Q4. Can I request to change the form of packaging and transportation?

A4: Yes, We can change the form of the packaging and transportation according to your request, but you have to bear their own costs incurred during this period and the spreads.

Q5. How long is your warranty?

A5: Our Warranty is 12 month.

- Q: Are plastic pipe fittings resistant to ozone?

- Yes, plastic pipe fittings are generally resistant to ozone.

- Q: Are plastic pipe fittings resistant to high-temperature fluids?

- No, plastic pipe fittings are generally not resistant to high-temperature fluids as they have lower temperature limits compared to materials like metal or other high-temperature resistant polymers.

- Q: Can plastic pipe fittings be used for fuel transfer systems?

- No, plastic pipe fittings are generally not recommended for use in fuel transfer systems due to their potential to degrade or become brittle when exposed to certain fuels, leading to leaks or failures. It is advisable to use fittings specifically designed and approved for fuel transfer applications, such as those made from materials like brass or steel.

- Q: Do plastic pipe fittings require any special protection against UV exposure?

- Yes, plastic pipe fittings often require special protection against UV exposure. UV rays from the sun can cause degradation and fading of plastic materials over time. To prevent this, UV stabilizers or additives are commonly used in the manufacturing process of plastic pipe fittings. Additionally, protective coatings or coverings can be applied to further shield the fittings from direct sunlight, extending their lifespan and maintaining their performance.

- Q: Are plastic pipe fittings resistant to sewer gas?

- Yes, plastic pipe fittings are generally resistant to sewer gas. They are commonly used in plumbing systems to prevent the escape of sewer gas, ensuring airtight connections and minimizing the risk of leaks.

- Q: Do plastic pipe fittings require any special reinforcement or clamping?

- Yes, plastic pipe fittings typically require special reinforcement or clamping to ensure a secure and leak-free connection. This is necessary to prevent any potential leaks or failures in the system.

- Q: Are plastic pipe fittings suitable for hot water systems?

- Yes, plastic pipe fittings are suitable for hot water systems. They are commonly used in residential and commercial applications due to their durability, corrosion resistance, and ease of installation. However, it is important to use fittings specifically designed for hot water systems and ensure they are installed correctly to prevent any potential issues.

- Q: Are plastic pipe fittings suitable for high-pressure applications?

- No, plastic pipe fittings are not suitable for high-pressure applications.

- Q: What is the maximum pressure rating for plastic pipe fittings?

- The maximum pressure rating for plastic pipe fittings can vary depending on the type and size of the fitting, as well as the material it is made of. However, commonly used plastic pipe fittings often have a maximum pressure rating of around 150-200 psi. It is important to consult the manufacturer's specifications or industry standards to determine the specific maximum pressure rating for a particular plastic pipe fitting.

- Q: How do you prevent leaks in plastic pipe fittings?

- One way to prevent leaks in plastic pipe fittings is to ensure a proper and secure connection. This can be achieved by using the correct size and type of fittings for the specific application, and following the manufacturer's instructions for installation. Additionally, it is important to use appropriate tools and techniques to tighten the fittings adequately without over-tightening, as excessive force can cause damage and lead to leaks. Regular inspections and maintenance, such as checking for signs of wear or damage, can also help identify potential leaks and prevent them from occurring.

Send your message to us

User-Friendly PPR Plastic Underground Water Pipe Fittings Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords