Plastic Elbow PPR Copper Pipe Fittings Plastic Material Female Coupling

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

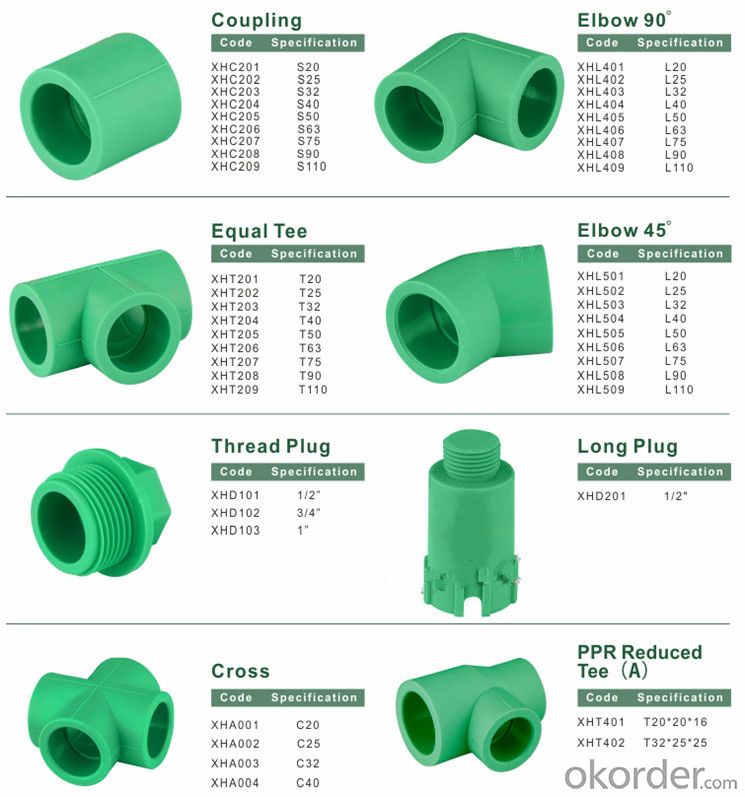

Specifications of PPR fittings pipe plastic material

1. size: 40-110mm

2. universal or OEM ODM

3.No heavy metal additives

China polypropylene fittings pipe plastic material of PPR fittings pipe plastic material

Recycled and Environmental friendly.

Applications of PPR fittings pipe plastic material:

1) Water supply systems: civil and industrial constructions, in residential buildings, hospitals,hotels,

school and office buildings, ship, building

2) Drinking water systems & food industry pipe works

3) Central air conditioning system

4) Irrigating system for gardens and green houses

5) Public and sport facilities: swimming pools & stadiums

6) Rainwater utilization systems

Features & Advantages of PPR fittings pipe plastic material:

1.Sanitization & Non-poison: It is green building material without heavy metal additives,able to be used for pure clean drinking water pipe system.

2.High Temperature Resistance: the maximum sustained working temperature is up to 70 Degrees Celsius, the maximum transient temperature is up to 95 Degrees Celsius.

3.Corrosion-proof & Non-fouling: Resist chemical matters & electron chemical corrosion, avoiding fouling,blocking, blemish, rust on basin and bath.

4.Beautiful Appearance & Higher Flow Capacity: Smooth inner and outer surfaces, les flowing resistance,

soft color and beautiful figure.

5.Easy and Reliable Installation: Using heat melting joint without sleeve wire, and taking few seconds for connecting and adopting good quality copper inserts to connect the metal pipe and basin.

6.Long Using Life: able to be used for over 50 years under normal condition.

Sizes of PPR fittings pipe plastic material:

Pictures of PPR pipes and fittings

Packing of PPR pipes and fittings:

FAQ:

1. why choose our factory ?

we are the professional ppr maufacuter the products series is very completely .

we have the professnial exported team more exprience ,reasonable price and best sales service . we have office

all overthe world .the customer is spread over the world .the exported market is the southeast ,asica,the

north and south america ,the european and middle east place so on !

2.How to order?

do not hesitate to contact by online or Email as soon as possible once you are interested in our products. The specific quotation will be offered basing the request dimension and quantity.x

3. Can you offer sample pipes and visit my factory?

Yes, we can. But as usual, the buyer have to pay the shipment fee for the sample.

4. What about the quality?

all products according to ISO and National highest standard, also we can offer CE, ASTM certificate if necessary. The guarantee and insurance is 50 years upon rational usage.

5. What payment is available?

Most payment method is available such as L/C, T/T and so on. At usual, 30% t/t deposited before producing and 70% C/L upon B/L for huge purchase.

6.the advantage for us ?

You may be looking for good plastic supplier hard, and you may waste of much time to find similar products at simiar price, and maybe some trading company is wasting your time to chose by higher price .P send your purchase list and you will see how professional we are.

7.Guaranteed:

If products’ quality don’t accord to discription as we give or the promise before you place order,

we promise 100% refund.Our service formula: best quality+best price+best service=customer’s trust

- Q: Are plastic pipe fittings resistant to sewer gases?

- Yes, plastic pipe fittings are generally resistant to sewer gases.

- Q: How do you connect plastic pipe fittings to PEX pipes?

- To connect plastic pipe fittings to PEX pipes, you can use compression fittings specifically designed for PEX plumbing systems. These fittings feature a compression nut and a sleeve that secure the PEX pipe onto the fitting. Simply slide the compression nut onto the pipe, insert the fitting into the pipe end, and tighten the nut to create a watertight connection.

- Q: Can plastic pipe fittings be used in high-temperature applications?

- No, plastic pipe fittings are not suitable for high-temperature applications as they have a lower melting point compared to metal fittings, which can cause deformation or failure under high heat.

- Q: Are plastic pipe fittings resistant to seismic movements?

- Yes, plastic pipe fittings are generally resistant to seismic movements. They are designed to be flexible and can withstand minor ground movements during earthquakes without breaking or leaking. However, it is important to ensure proper installation and use appropriate seismic-resistant fittings for areas prone to frequent earthquakes.

- Q: Can plastic pipe fittings be used for freshwater aquaculture systems?

- Yes, plastic pipe fittings can be used for freshwater aquaculture systems. They are commonly used due to their durability, corrosion resistance, and affordability. Plastic pipe fittings are easy to install, maintain, and can withstand the water conditions typically found in freshwater aquaculture systems.

- Q: How do plastic pipe fittings compare to polypropylene fittings?

- Plastic pipe fittings and polypropylene fittings are both types of plastic fittings commonly used in plumbing systems. However, there are some differences worth noting. Plastic pipe fittings are a broad category that includes fittings made from various types of plastic materials, such as PVC, CPVC, and ABS. On the other hand, polypropylene fittings are specifically made from polypropylene, a thermoplastic polymer known for its high chemical resistance and durability. In terms of performance, polypropylene fittings generally offer superior chemical resistance, making them more suitable for applications involving corrosive or aggressive fluids. They are also known for their high temperature resistance and mechanical strength. Plastic pipe fittings, on the other hand, can vary in terms of quality and performance depending on the specific material they are made from. Another important aspect to consider is the ease of installation. Both plastic pipe fittings and polypropylene fittings are typically designed for solvent welding or using mechanical connections. However, polypropylene fittings often have a more precise and secure fit due to their tighter tolerances, which can simplify the installation process and reduce the risk of leaks. Ultimately, the choice between plastic pipe fittings and polypropylene fittings depends on the specific application requirements, such as the type of fluid being transported, the temperature and pressure conditions, and the chemical compatibility needed. It is important to consult with professionals or follow the manufacturer's recommendations to ensure the right choice for each individual case.

- Q: Are plastic pipe fittings suitable for pharmaceutical manufacturing?

- Yes, plastic pipe fittings can be suitable for pharmaceutical manufacturing. They offer various advantages such as chemical resistance, low cost, easy installation, and flexibility. However, it is essential to ensure that the chosen plastic material and manufacturing processes comply with the industry's strict quality and safety standards to prevent any potential contamination risks.

- Q: Can plastic pipe fittings be used for CO2 capture systems?

- Yes, plastic pipe fittings can be used for CO2 capture systems. However, it is important to ensure that the chosen plastic material is compatible with CO2 and can withstand the pressure and temperature conditions of the system. Additionally, proper sealing and jointing techniques should be employed to prevent any leaks or loss of captured CO2.

- Q: Can plastic pipe fittings be used for geothermal heating and cooling systems?

- Yes, plastic pipe fittings can be used for geothermal heating and cooling systems. Plastic pipes, such as high-density polyethylene (HDPE) or cross-linked polyethylene (PEX), are commonly used in geothermal systems due to their durability, resistance to corrosion, and flexibility. These pipes can effectively handle the high temperatures and pressures associated with geothermal systems, making them a suitable choice for this application. Additionally, plastic pipe fittings are lightweight, easy to install, and often more cost-effective compared to other materials used in geothermal systems.

- Q: How do you prevent leaks in plastic pipe fittings?

- To prevent leaks in plastic pipe fittings, it is essential to follow a few key steps. Firstly, ensure that the pipe ends are clean and free from any dirt or debris. Next, use proper tools to tighten the fittings securely, avoiding over-tightening which may damage the threads. Applying a suitable sealant or thread tape to the male threads can also help create a watertight seal. Finally, regularly inspect the fittings for any signs of wear or damage, and promptly replace any faulty components to prevent leaks from occurring.

Send your message to us

Plastic Elbow PPR Copper Pipe Fittings Plastic Material Female Coupling

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords