Us Fabrics Geotextile Non Woven Geotextile for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

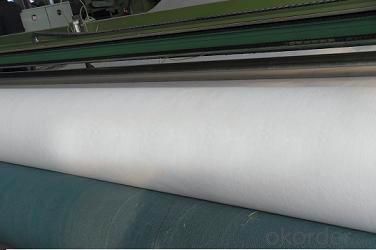

Structure of Non Woven Geotextile Description:

Nonwoven geotextiles are multi-purpose fabrics that are felt-like in appearance.Nonwoven Geotextiles are available in varying strengths and thicknesses to ensure appropriate material selection for your project. Custom roll sizes are also available.

Main Features of the Non Woven Geotextile:

1.Separation

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different

granule pathway from the groundsill or other buildings.

2.Reinforcement

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earthbody stability.

3.Protection

It prevents the bank from being washed out, protects the bank and the

bottom, prevents the water and soil from being washed away

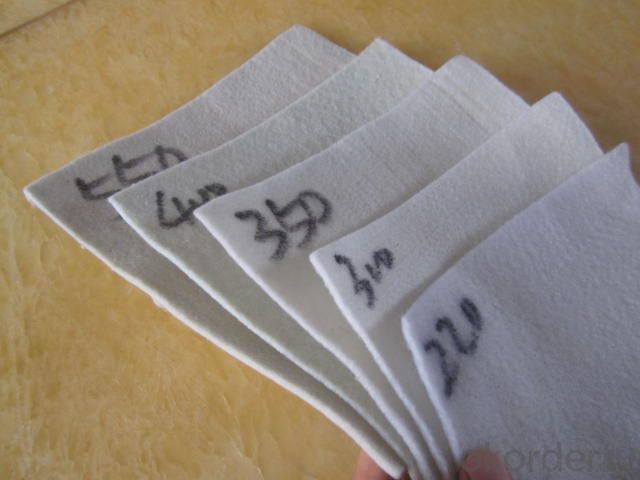

Non Woven Geotextile Images

Non Woven Geotextile Specification:

Material | PET(polyester) OR Polypropylene |

Weight | 100g/m2-800g/m2 |

Width | 1-6m |

Length | 100m(or as your demand) |

Packing | Standard Export Packing. Or Packed as customers' requests. |

Payment terms | TT/LC |

Delivery time | 15-30days |

Items | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | Note |

Quality error in unit area% | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 | |

Thickness .mm.≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

Error of width.% | -0.5 | |||||||||||

Breaking strength,KN/m≥ | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | CD MD |

Elongation at break≤(%) | 25-100 | |||||||||||

CBR bursting strength KN≥ CBR | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 | |

Effective aperture090(095)mm | 0.07-0.2 | |||||||||||

Vertical permeability coefficient cm/s | Kx(10-4-10-3) | K=1.0-9.9 | ||||||||||

Tearing strengthKN≥ | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.60 | |

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2.Does your products have good qualitity?

A2:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q3:How long can we receive the products after purchase?

A3:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: How do geotextiles contribute to sustainable construction practices?

- Geotextiles contribute to sustainable construction practices by providing numerous benefits such as soil stabilization, erosion control, and drainage management. These textile materials act as a barrier, preventing the loss of soil particles and reducing the need for excessive excavation or grading. By minimizing soil erosion and improving water drainage, geotextiles help maintain the structural integrity of construction projects while also minimizing environmental impacts. Additionally, they can be made from recycled materials, promoting sustainability by reducing waste and utilizing existing resources.

- Q: How do geotextiles help in the construction of ponds and lakes?

- Geotextiles help in the construction of ponds and lakes by providing erosion control, filtration, and separation. They are used as a barrier to prevent soil erosion, stabilize the embankments, and retain water within the pond or lake. Geotextiles also act as a filtration medium, preventing the migration of fine particles and allowing water to flow freely. Additionally, they help in separating different layers of soil, preventing mixing and maintaining the structural integrity of the pond or lake.

- Q: How do geotextiles prevent soil contamination?

- Geotextiles prevent soil contamination by acting as a barrier that separates the soil from potentially harmful substances, such as pollutants or contaminants. It helps to filter and retain these substances, preventing them from leaching into the soil and affecting its quality. Geotextiles also aid in erosion control, reducing the risk of soil contamination caused by sediment runoff.

- Q: Weaving geotextile construction should pay attention to what

- Weaving geotextile construction specifications: 1, before the construction of roadbed should be integrated clean up, the surface shall not have sharp corners. 2, geotextile is best to use mechanical erection, can also be used artificial laying. When laying, it should be noted that the rough side of the singeing up, and then one end fixed with a fixed, mechanical or human tension, tensile elongation of about 1 & amp;% to 1 & amp;%, Facing front laying. The fixture includes fixed and fixed metal. Fixed nails should be used cement nails or nails, nail length 8 ~ 10cm fixed iron can be thick lmm, width 3mm of the strip. 3, weaving geotextile and the length of the long, should be used industrial sewing machine sewing, sewing method using "dow" and "seam". Suture and geotextile should have a significant color difference in order to facilitate inspection.

- Q: What are the factors that affect the effectiveness of geotextiles in erosion control?

- The effectiveness of geotextiles in erosion control is influenced by several factors. Firstly, the material and quality of the geotextile itself play a significant role. Geotextiles with higher tensile strength and durability are more effective in preventing erosion. Secondly, the design and installation of the geotextile are crucial. Proper placement and anchoring techniques ensure that the geotextile remains in place and functions effectively. The type and intensity of the erosive forces also impact the effectiveness of geotextiles. Factors such as water flow rate, soil type, slope gradient, and vegetation cover can affect how well the geotextile mitigates erosion. Additionally, the maintenance and regular inspection of the geotextile are important for its long-term effectiveness. Overall, a combination of material quality, proper installation, and consideration of site-specific conditions contribute to the effectiveness of geotextiles in erosion control.

- Q: What is the consequence of the geotextile of the ground floor

- What are the consequences of what can not be finalized, the first roof of the waterproof layer and waterproof protective layer is very important, this is the first barrier, imagine, now many of the green plants are large trees, grow 10 years or even 20 years After the roots will be very developed, think about how the pine trees on the tenacious know their strength, coupled with long-term erosion by the water, the concrete layer will gradually lose its ideal performance, barrier layer and drainage board will certainly be better To protect the role and drainage. Well, long-term perspective, then we must do a solid job every layer, only focus on economic interests and short-term effects, then, within a few years will not be any problem, this is the status of China's construction industry. But the debt owed sooner or later.

- Q: Can geotextiles be used in soil erosion control on construction sites?

- Yes, geotextiles can be used in soil erosion control on construction sites. Geotextiles act as a barrier that prevents soil erosion by stabilizing the soil and allowing water to drain through while retaining sediment. They are commonly used in construction projects to protect slopes, control sediment runoff, and promote vegetation growth, thereby reducing the risk of soil erosion on construction sites.

- Q: How do geotextiles help with filtration in drainage systems?

- Geotextiles act as a barrier in drainage systems, allowing water to pass through while preventing the passage of soil particles or other contaminants. By filtering out these particles, geotextiles help maintain the integrity and functionality of the drainage system, ensuring efficient water flow and preventing clogging or blockages.

- Q: How do geotextiles help in preventing soil compaction?

- Geotextiles help in preventing soil compaction by providing a barrier between the soil and external forces. They distribute the load evenly across the surface, reducing direct pressure on the soil and preventing it from being compacted. Additionally, geotextiles improve soil drainage, allowing excess water to flow through and preventing waterlogged conditions that can lead to compaction.

- Q: Road overhaul of the original concrete pavement after shaving asphalt, anti-cracking is geotextile or geogrid more

- Generally used in the geotextile, generally used in soft foundation reinforcement treatment; slope protection; road anti-reflective crack structure layer; drainage system; green belt

Send your message to us

Us Fabrics Geotextile Non Woven Geotextile for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords