Trampoline Spring for Industry Use, Automatic Use

- Loading Port:

- Ning Bo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500Pieces pc

- Supply Capability:

- 3000000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

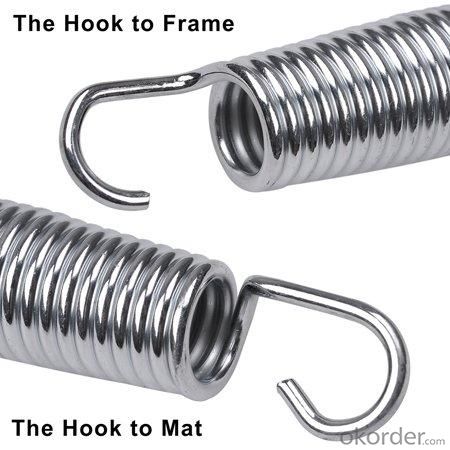

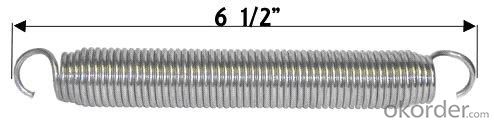

Specifications of Trampoline Springs

1. design as customers' requirement

2. good quality,competitive price,fast deliverytime

Our Advantage:

1. Over twenty years of production experience

2. Surface Treatment

zinc/chrome/nickel plated, plaint black, Oxisized, powder coating,

cataphoresis or as your request

3. Certification

ISO9001:2000, ISO14001: 2004,ROHS

4. Applications

Extensively used for Industry, Automotive, medical device, agricultural

Machinery, electronics, toy

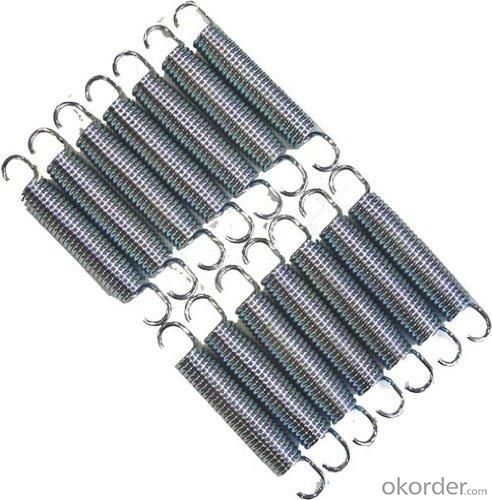

5. Packing

Inner plastic bags and outer cartons or as per customers' requirements

6.good quality,competitive price,fast deliverytime

The Material You Can Choose:

Alloy Steel | Nickel Base Alloy |

| Chrome Silicon Springs | Beryllium Nickel Spring |

| Chrome Vanadium Springs | Hastelloy Spring |

| Inconel 600 Spring | |

| Carbon Steel | Inconel X750 Spring |

| AISI 1050 Spring | Monel 400 Spring |

| AISI 1074, 1075 Spring | Monel K500 Spring |

| AISI 1095 Spring | Nimonic 90 Spring |

| Hard Drawn Spring | Nitronic Spring |

| Music Wire Spring | Rene 41 Spring |

| Oil Tempered (OTMB) Spring | |

| Valve Spring | Copper Base Alloy |

| Beryllium Copper Spring | |

| Stainless Steel | Brass Spring |

| 17-7 PH Spring | Copper Spring |

| Alloy 20 Spring | Phosphor Bronze (A) Spring |

| CRES 18-8 Spring | Spring Brass, CA260 Spring |

| NiCr A286 Spring | |

| Stainless Steel 301 Spring | Titanium |

| Stainless Steel 302 Spring | Beta C Titanium Springs |

| Stainless Steel 304 Spring | |

| Stainless Steel 316 Spring |

Packaging and Transportation

Application of Trampoline Springs

- Q: Want to practice how to use pectoral muscle spring expander

- The most simple way you can lie on the bed or on the floor and chest stretching is very effective and pay attention to more, so as not to hurt the small set of muscles.It takes at least one month to bear fruit

- Q: Stainless steel and spring steel hardness, who is hard?

- You should say that the deformation resistance, spring steel generally high strength, large deformation resistance, generally speaking, stainless steel generally than spring steel deformation easier, and some varieties of stainless steel deformation resistance is also very large

- Q: Hydraulic diagram of the one-way valve has two kinds of drawing, with a spring, without a spring, what is the difference between automatic reset function is not? Without a spring, it will not be repeated

- General one-way valve is spring to reset, as for drawing may be the standard of drawing is not the same. As long as no oil passes, it closes.

- Q: What is spring pressure and height?

- Press the compression spring to the point where each circle is tight. Press it and press it high

- Q: I buy a spring made of 1.2mm steel wire from a hardware store that needs quenching

- In general, hot bending spring coil spiral spring and disc spring of hot stamping, preferably in hot forming and quenching by the heat immediately. In this way, the heating and the decarburization degree of the spring can be omitted, and the surface quality of the spring can be improved both economically and at the same time.

- Q: How to choose spring steel material?

- Spring steel is selected on the basis of the section size of the spring, such as high carbon steel 65, suitable for production in the spring of 12 ~ 15mm under section 60CrMnA, suitable for the production of spring and the car less than 50mm in diameter with heavy-duty spring. The 30W4Cr2VA is used to make heat-resistant spring for work below 500 degrees centigrade. Generally, hot forming springs are generally quenched and tempered at moderate temperature to obtain a structure with a maximum elastic limit and fatigue properties

- Q: The shop glass spring door is too tight, how to adjust?

- If it is the glass door of the ground spring, then call the installation worker to loosen it.

- Q: What are the main functions of spring?

- Measure the magnitude of forces, such as springs, scales, and springs in a dynamometer

- Q: How to distinguish between spring steel and stainless steel

- Stainless acid resistant steel, or stainless steel, is made up of two parts: stainless steel and acid resistant steel. In short, steel that resists atmospheric corrosion is called stainless steel, and steel resistant to chemical corrosion is called acid resistant steel. Spring steel is a quality carbon steel, but it can rust.

- Q: In short, in vibration and wave, it is not easy to make mistakes when we grasp the difference and relationship between "displacement" and "displacement relative to the balance position"

- In short, in vibration and wave, it is not easy to make mistakes when we grasp the difference and relationship between "displacement" and "displacement relative to the balance position"

1. Manufacturer Overview

| Location | Suzhou, China |

| Year Established | 2001 |

| Annual Output Value | more than US$ 5 Million |

| Main Markets | North America, South America, Eastern Europe, Southeast Asia, Africa, Mid East, Eastern Asia, Western Europe |

| Company Certifications | ISO/TS 16949; ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | About 170 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | About 35,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Trampoline Spring for Industry Use, Automatic Use

- Loading Port:

- Ning Bo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500Pieces pc

- Supply Capability:

- 3000000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches