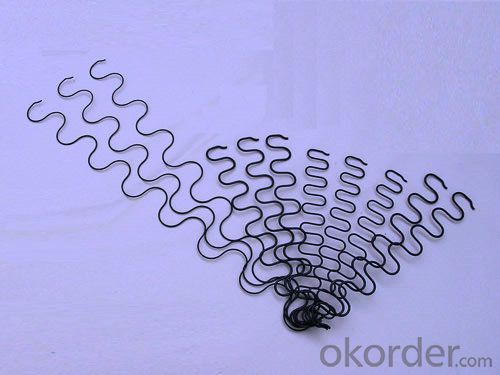

SERPENTINE SPRING AND LOW PRICE! AND GOOD QUALITY!

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification | |

Usage: lockable gas spring/locking gas strut for medical bed ,medical equipment, office chair. | |

| Features: | |

1, Gas: Nitrogen filled inside. | |

2, Color : black, silver,or as clients request. | |

3,Quality: We can provide fatigue test report. Our products can open and close 100,000 times, Not leak oil; Our paint is passed ROHS test; | |

4,When the gas spring is up and down, it's smooth operation without noise. | |

5,Safe and easy installation. | |

6,Reasonable price, excellent quality, delivery soon, good service. | |

7,MOQ: 100PCS. | |

Packing: Standard export packing or as the request. | |

| Item | Description |

| Product Name | Spring |

| Wire Diameter | 0.01 to 12mm |

| Style of precise spring | coil/spiral/conical spring ;compression/extension/tension/torsion spring |

| Material | Stainless steel, carbon steel, spring steel, alloy spring steel, refractory steel, brass, and bronze (most of them are imported from Korea, Germany and Japan) |

| Surface Treatment | Zinc-plated, nickel-plated, chrome-plated, silver-plated, gold-plated, imitation gold-plated, etc. |

| Packing | Inner-Plastic Bag; Outer -Standard Carton Box. |

| Usage | All kinds of cars, machinery, home appliance, electronic products, electric appliance, stationery, computers, power switches, miniature switches, architecture, commodity and A/V equipment, hardware and plastic molds, sports equipment and gifts, and more |

| Quality Control | Conducted by ISO/TS16949:2002 and ISO14001:2004 system. |

| Equipments | Advanced CNC spring machinery; Advanced grinding and shot peening machinery; Precise tensile strength testers, compression testers, endurance testers, and magnetic powder flaw detectors |

| Applications | auto,motorcycle,industry,ariculture,mine,furniture,elevator,etc |

| Technical | Experienced engineers and technicians; Skilled Workers; |

| File Format | Solidworks,Pro/Engineer,Auto CAD,PDF,JPG |

| Service | Warm and quick response service provided by the professional Export Sales Team with many years' experience in handling exports to the US, Europe, Japan and other countries and regions. |

- Q: Is spring steel manganese steel?

- With wings are not necessarily the "angel", also may be "bird". Steel not containing Mn elements is called manganese steel. Manganese steel refers to those with high strength steel, mainly used for impact, friction and extrusion, mainly wear and tear.

- Q: Stainless steel and spring steel hardness, who is hard?

- Hardness is checked by indentation, not by pliers.Stainless steel, of course

- Q: Spring dynamometer and spring balance what is the difference

- Spring dynamometer is a force measuring spring balance is to measure the quality of

- Q: Can springs be used for support?

- The following individual ideas do not represent the bestFriction is bound to damage,Gaskets can be used to prevent direct friction between the spring and gear to lubricate, optimize wear and prolong life.

- Q: What's the manganese content of spring steel?

- Carbon spring steelThe carbon content (mass fraction) of carbon spring steel is usually 0.62%~0.90%. In accordance with its manganese content is divided into general manganese content (mass fraction) (0.50%~0.80%), such as 65, 70, 85 and higher manganese content (mass fraction) (0.90~1.20%), such as 65Mn two categories.

- Q: How to choose spring steel material?

- The cold plastic deformation of the cold drawn spring material is high, and most finished steel wires have reached the required mechanical properties when the steel mill is out of the factory. The surface quality of the steel wire is high, and the spring manufacturing process is simple. For springs of medium or small spring or high fatigue life, the cold spring or cold drawn spring or steel wire or strip shall be selected as far as possible. Carbon spring steel wire (group I, group II, group II A, dish group) and important uses of 65Mn spring steel wire during the cold drawing process caused in large residual stress, the larger the size change after low temperature tempering, and thus affect the dimensional accuracy of the spring. This kind of steel wire should be used preferentially for the tension spring with small bending radius and the compression spring with smaller diameter of steel wire. Oil tempered steel wire for residual stress, cold forming, precision spring is easy to control, low temperature tempering after the size change is very small, especially because there is no residual stress relaxation resistance than carbon spring steel wire lead quenching and cold drawing good. For the spring with higher size precision and the thicker diameter of spring steel and the good spring resistance, the oil quenching and tempering steel wire shall be used.

- Q: What kind of spring has the best performance?

- Spring surface scars, spring surface injury to use a magnifying glass to see, manufacturers generally use 300 times electronic magnifying glass, spring 300 times, see the injury, the impact on life is very big.

- Q: Cold rolled coil spring spring and difference "

- The main production process is different, the compression spring as an example:The typical process of coil spring: blanking - end processing (rolled or forged flat) - heating - - - quenching - tempering spring roll grinding end - compressor (load - Test), shot peening (cleaning) - coating.Cold roll spring does not require heat treatment of material roll, point line process: rolling, annealing, stress to both ends of the surface grinding, (blast), (the whole school), (BKS), standing or forcing treatment, surface inspection and treatment.Coil spring is mainly used for rolling large spring, heating easily after twisting forming, springback is smaller, molding after quenching and tempering treatment.The cold coiling spring is directly coiled with spring steel wire, and the resilience is greater, and the winding tools need to consider the springback compensation amount and roll into the direct tempering process.

- Q: How about the size of the elasticity?

- Also called elastic force". The object by the force deformation, if the external force is removed, the object can return to its original shape of the elastic force, called "". Its direction is opposite to the external force that causes the object to deform. There are many different kinds of deformation, so there are different forms of elasticity. For example, when a heavy object is placed on a plastic sheet, the bent plastic should be restored to its original state and produce upward elasticity, which is its support for the heavy object. Hanging an object on a spring, the object stretched the spring, the elongated spring to restore the original state, resulting in upward elasticity, which is its pulling force on the object. Not only plastic, spring and so on can occur deformation, any object can deformation, no deformation of the object does not exist. However, some of the deformation is obvious, can be seen directly; some deformation is very small, must be aware of the instrument.

- Q: How to process Spring Steel

- Spring steel has excellent comprehensive performance, spring steel has excellent metallurgical quality (high purity and uniformity), good surface quality (strict control of surface defects and decarburization, precise shape and size).

Send your message to us

SERPENTINE SPRING AND LOW PRICE! AND GOOD QUALITY!

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches