Hydraulic Door Hinge /Floor Spring/Floor Hinge for Glass Door FS-75

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

INTRODUCTION

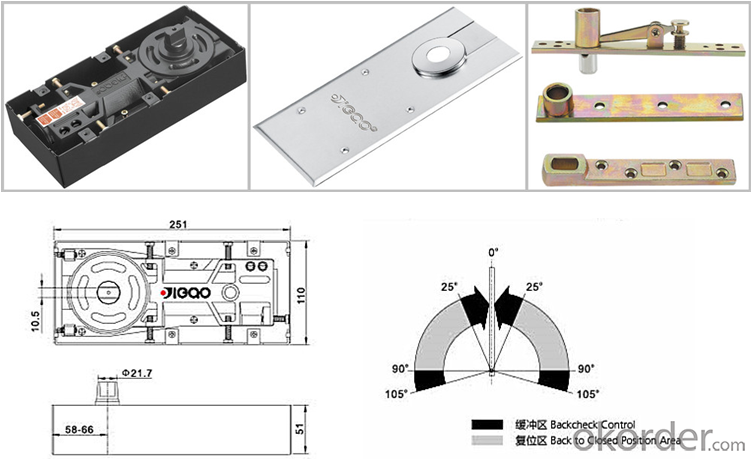

Floor Spring is used for glass door, and they can be used together with door clamp. Floor Spring can be opened with double sizes, and on this point, it is different from that of door closer, which can just be opened by one size. The key of technique lies on the loading seat under the main bearing, which decides the level of loading on the floor spring. Usually it can be opened from 300thousand or 1million times

FEATURES

u Applicable for glass doors, wooden doors and the glass doors of metal frame and wooden frame.

u Floor spring comply to EN 1154 and GB standard , and fire-rated EN1634 standard.

u Maximum 500000 cycles tested without damage or maximum 7 years guarantee.

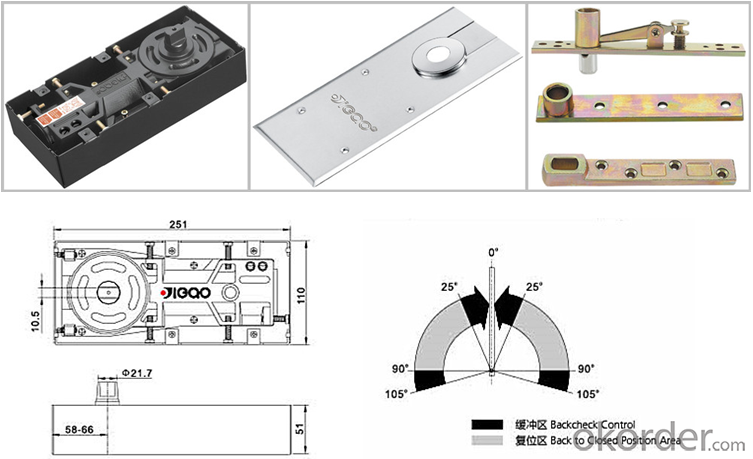

u Double ways opening with smoothly movement, hold-open at 90°.

u Closing speed and latching speed adjustable, latching point accurately at 0°

u Stainless steel cover plate, satin or mirror surface available.

u High quality casting iron floor spring body with 2 layers anti-rust coating.

u All spindle types available for different countries.

u Germany hydraulic machine oil and sealed rings, keep perfect working in cold temperature.

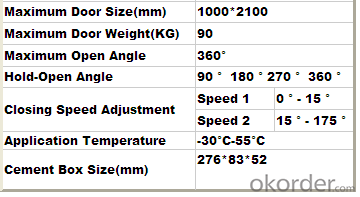

SPECIFICATION

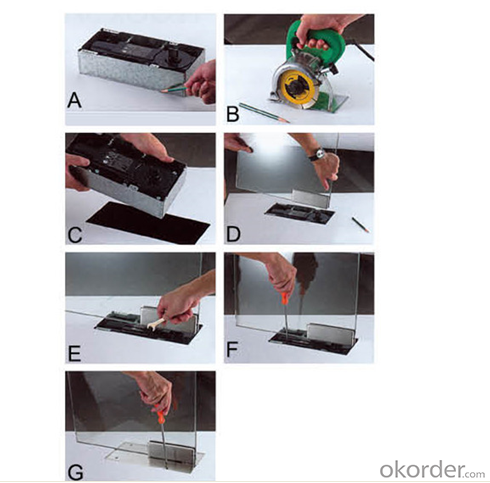

INSTALLATION STEPS

1. Draw lines and make floor spring pivot center and door-nip pivot coincide with each other.

2. Drill holes on the floor according to the instructions. The sizes of the holes must tightly match the floor spring.

3. Place the floor spring into the holes and position it.

4. Raise the door leaf installed with door-nip, and insert the floor spring pivot into the hole of the door leaf.

5. Adjust the screws at three directions. Make them vertical and the upper and lower pivot center coincide with each other.

6. Adjust the speed of door closing.

7. Put the decoration cover on the floor spring.

- Q: What kind of production equipment does spring factory usually have?

- Multi function forming machine, coil spring machine, 580 press spring machine, extension spring machine, etc.Small heat treatment is also needed

- Q: What's the spring material to?

- There are many kinds of spring steel, the most commonly used are 65Mn and 60Si2Mn.

- Q: What is flat steel? Plain carbon flat steel? Spring flat steel

- Section steel is one of the four major steel products (plate, tube, mould, wire). According to the section shape, the section steel is divided into simple section steel and complex section steel (deformed steel). The former refers to the steel, round steel, flat steel, angle steel, six angle steel; the latter refers to the I-beam, channel steel, steel, steel, steel frame bending etc.. Square, square section steel, cold and hot points in two; length of hot-rolled square steel 5-250mm; cold drawn steel length 3-100mm. Round - round section steel, hot, forged and drawn three, hot-rolled bar diameter 5-250mm, which 5-9mm used as drawing steel wire material, called wire; due to disk supply is also called hot rod. Forged round steel is thicker, used as axle billet. Cold drawn round steel diameter 3-100 mm, high dimensional accuracy. Flat - width 12-300mm, thickness 4-60mm, cross section is rectangular and with pure edge of steel. Flat steel can be finished steel, or can be used as the blank of welded pipe and thin slab for laminated sheet rolling. Angle steel -- two kinds of grade angle steel and unequal angle steel. The dimension of angle iron is expressed by the dimension of the length of side and the thickness of edge. The standard angle steel, usually produced, is 2-20, which is the centimeter side length. Such as 5 equal angles, that is, the length of 5cm (50mm) angle steel. The same horn steel often has 2-7 different edge thickness. Steel bars are not the classification of profiled steel. First, the basic concepts of ferrous metals, steels and nonferrous metals are briefly introduced before introducing the classification of steels, ferrous metals, steels, and nonferrous metals. 1. Ferrous metals are alloys of iron and iron. Such as steel, pig iron, iron alloy, cast iron and so on. Steel and pig iron are both...

- Q: What is an independent bagged spring?

- The characteristics of independent bagged springs is independent bagged spring each spring can be independent of support, stretching alone, completely conform to the body curve, so that all parts of the body are the best care, with ergonomic, closely supporting effect. Spring tube respectively operation, a force, not elsewhere, even if the pillow was over, it will not affect the sleeping of another, especially by adding a layer of high elastic cotton blanket and wave type sponge bed, bump by using body wave sponge flip natural movement to achieve the massage and health care enjoy the ultimate role of sleep.

- Q: How should we choose the spring material?

- Whether the spring is good or not is of great importance to the choice of the spring material. In general, selection of spring material, should take into account the load properties, spring force, various factors should be size, working conditions and price, etc.. Specific can follow the following principles: 1) in determining the shape and size of spring material, should be preferred dimensions behind national standards or standard stipulated, try to avoid using non standard materials. Although the spiral spring square or rectangular cross section material, the elastic deformation can be higher than, can make the small volume of the spring, for spring, in small space or under impact load but because of square or rectangular section material shortage, the price is higher, and the spring forming is difficult, so should be avoided. Ring section spring material diameter series see table 3-9. 2) the degree of cold plastic deformation of cold drawn spring materials is high. Most finished steel wires have reached the required mechanical properties when they leave the factory. The surface quality of the steel wire is high, and the manufacturing process of the spring is simple. For springs of medium or small spring or high fatigue life, the cold spring or cold drawn spring or steel wire or strip shall be selected as far as possible. Carbon spring steel wire (group I, group II, group II A, dish group) and important uses of 65Mn spring steel wire during the cold drawing process caused in large residual stress, the larger the size change after low temperature tempering, and thus affect the dimensional accuracy of the spring. For the bending radius of smaller tension and torsion spring, as well as smaller steel wire compression...

- Q: Cold rolled coil spring spring and difference "

- Difference: the main annealing time is different. In the production process, is the first volume of coil spring and annealing, and spring is the first cold roll annealing, and then roll. Similar to cold rolling and hot rolling of steel.Note: spring making methodProduction method of cold rolled coil spring: to stress annealing, end surface grinding, (blast), (the whole school), (BKS), standing or forcing treatment, surface inspection and treatment.Production method of coil spring: blanking, end processing (rolled or forged flat), heating, coiling, quenching, tempering, grinding end to compression to (load test), shot peening (cleaning), coating.

- Q: Is the car short spring good?

- Hello: no modification is recommended! Although the spring shortening can reduce the height of the body to make the car appear more sporty, it can also reduce partial roll during cornering. But it does more harm than good. Below say, change the disadvantage of short reed. First of all, lowering the body will affect the passing, and the over speed belt is easy to drag the chassis. Another major drawback is that the full set of shock absorbers consists of a helical spring and a hydraulic cylinder shock absorber.

- Q: What are the main functions of spring?

- Measure the magnitude of forces, such as springs, scales, and springs in a dynamometer

- Q: How to distinguish between spring steel and stainless steel

- Stainless acid resistant steel, or stainless steel, is made up of two parts: stainless steel and acid resistant steel. In short, steel that resists atmospheric corrosion is called stainless steel, and steel resistant to chemical corrosion is called acid resistant steel. Spring steel is a quality carbon steel, but it can rust.

- Q: Physics high school. Why does a spring fall to the lowest point and the acceleration a must be greater than the acceleration of gravity g ah. Seek expert

- Is the map tilted?.Look at the picture. It means that a naturally stretched spring is placed vertically and then put a mass of m at zero initial speed.If dropped to the lowest point, the speed of the object v=0, object by the acceleration of gravity g down, if not spring to give it an g greater than or equal to the acceleration, the object will continue to fall, do not conform to the original intention of "low".So the acceleration inside the spring must be greater than or equal to g.

Send your message to us

Hydraulic Door Hinge /Floor Spring/Floor Hinge for Glass Door FS-75

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords