Compression Spring with Zinc, Tin, Nickel

- Loading Port:

- Nansha

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 Piece/Pieces pc

- Supply Capability:

- 300000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

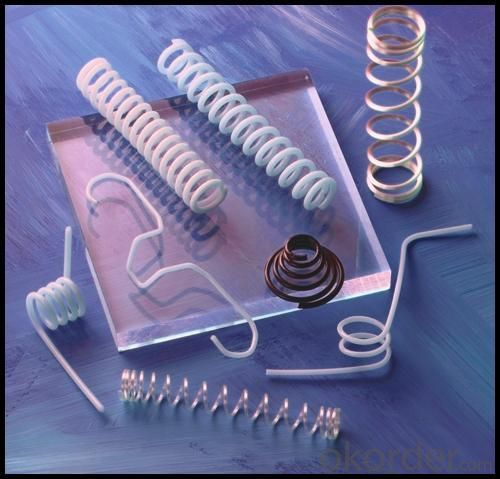

Specifications of Compression Spring

1. high quality

2.very competitive price.

3.timely delivery

4.good service after-sale

Compression spring

high carbon steel compression spring,stainless steel compression spring,

all kinds of compression spring,compression spring

manufacturer,high quality compression spring,custom compressions spring.

China compression spring.xiamen compression spring

Material | Spring Steel |

| Stainless Steel | |

| Low Carbon Steel | |

| High Carbon Steel | |

| Music Wire / Piano Wire | |

| Galvanized Steel | |

| Hard Drawn | |

| Non-ferrous Metals | |

| Surface Finish | Zinc/ Tin/ Nickel/ Chrome Plating, Black Oxide, Color Painted, PVC/ Powder Coating, |

| Shot Blasting, Anodizing, Plain, Polishing, Passivate, Electorolysis | |

| Wire Diameter | 0.1 ~ 8.0 mm |

| 0.004 ~ 0.315 in | |

| Outer Diameter | 4.0 ~ 80 mm |

| 0.157 ~ 3.15 in | |

| Direction of Wind | Left Hand |

| Right Hand | |

| Optional | |

| Packaging Detail: | inner packing: PE bag, outer packing: corrugated carton or box due to customer's requirement |

Packaging & Delivery

Packaging Detail: inner packing: PE bag,

outer packing: corrugated carton or box due to customer's requirement

Delivery Detail: 5-7days

- Q: Buffer spring buffer for automobile

- Next, put a soapy water or lubricant on the loose coil spring. Then, insert a strong buffer of soap, water or lubricant into the loose spiral spring gap, and then release the car body after confirming it.Finally, the distance between the damping springs is a matter of concern for mounting the shock absorber. The distance between the springs is equal to the length of the shock absorber. If it is more difficult to squeeze by hand, loosen the screw of the shock absorber, and let the damping spring relax 2 - 3 centimeters.

- Q: Hydraulic diagram of the one-way valve has two kinds of drawing, with a spring, without a spring, what is the difference between automatic reset function is not? Without a spring, it will not be repeated

- General one-way valve is spring to reset, as for drawing may be the standard of drawing is not the same. As long as no oil passes, it closes.

- Q: What is spring pressure and height?

- Press the compression spring to the point where each circle is tight. Press it and press it high

- Q: Can springs be used for support?

- One point, the spring you choose to bear the force is higher than the gear weight pressure, if higher than, then the spring to withstand 0. Unless the heat changes, the spring steel is denatured. Long periods of rust change can also make a difference. Deal with the above two points. 0 pressure spring does not exist short pressure

- Q: What kind of material does spring have?

- 65MnSpring steel belongs to the mechanical structure steel; according to the quality grade, it belongs to the special quality steel, that is to say, in the process of production, it is necessary to strictly control the quality and performance of the steel.

- Q: How to choose spring steel material?

- In choosing materials, the material shall be considered in combination with the diameter or thickness of the material. The size of commonly used spring steel in oil is shown in table 3-10.7mm below diameter carbon spring steel used for oil quenching, the size of all kinds of spring is slightly larger, available manganese spring steel quenching. Well, such as 65Mn spring steel 15mm diameter can be through quenching in oil, available water quenching diameter of 25mm. For the spiral spring, leaf spring and disc spring middle section can be used manganese spring steel, 60Si2Mn steel can be used as oil quenching diameter of 25mm, for the spring to withstand heavy loads with large cross section, can choose the hardenability of high chromium silicon steel, chrome vanadium steel wire, such as 60Si2CrA.50CrVA, 45mm in diameter can also through quenching in oil.

- Q: What kind of spring has the best performance?

- Spring verticality, verticality is bad, will directly affect the strength and life.

- Q: Is the car short spring good?

- Hello: no modification is recommended! Although the spring shortening can reduce the height of the body to make the car appear more sporty, it can also reduce partial roll during cornering. But it does more harm than good. Below say, change the disadvantage of short reed. First of all, lowering the body will affect the passing, and the over speed belt is easy to drag the chassis. Another major drawback is that the full set of shock absorbers consists of a helical spring and a hydraulic cylinder shock absorber.

- Q: How to distinguish between spring steel and stainless steel

- With saline in two days to put a steel can see rust is a way (can, for 304 stainless steel 201 stainless steel will rust, only less); another way is to put the two kinds of steel can see the reaction is on spring steel in dilute sulfuric acid, oxalic acid, not the reaction or reaction of small stainless steel.

- Q: In short, in vibration and wave, it is not easy to make mistakes when we grasp the difference and relationship between "displacement" and "displacement relative to the balance position"

- In short, in vibration and wave, it is not easy to make mistakes when we grasp the difference and relationship between "displacement" and "displacement relative to the balance position"

1. Manufacturer Overview

| Location | Suzhou, China |

| Year Established | 2001 |

| Annual Output Value | more than US$ 5 Million |

| Main Markets | North America, South America, Eastern Europe, Southeast Asia, Africa, Mid East, Eastern Asia, Western Europe |

| Company Certifications | ISO/TS 16949; ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | About 170 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | About 35,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Compression Spring with Zinc, Tin, Nickel

- Loading Port:

- Nansha

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 Piece/Pieces pc

- Supply Capability:

- 300000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords