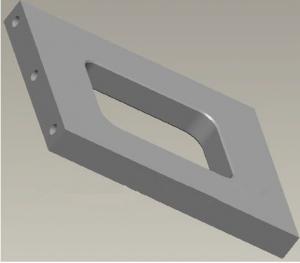

Mould Spring with free design

- Loading Port:

- Ning Bo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000Pieces pc

- Supply Capability:

- 100000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The Specifications of The Mould Springs

Product Name | Compression mould spring | Supply Ability | 900000000PCS | ||

| Wire diameter | 0.08mm~10.0mm | Type of shipping | By sea/air/DHL/Fedex/UPS etc | ||

| Quality certification | ISO9001:2008.SGS,the French | Payment term | L/C,T/T,D/A,D/P,Western union,Money Gram,Paypal | ||

| BV authentications | |||||

| The scale of Hershey spring | About 6000 suqare meters | Employee numbers | About 100.and our group are becoming larger | ||

| Industry Experience | Over 21 years' experience in the spring industry. | ||||

Mould Spring Production and Manufacturing

1.Our engineers are eager to help provide the most dependable mould

spring for your applications. Our company is a mould spring

manufacturer that you can depend on to deliver high quality mould

spring with speedy lead times

2.Specialiaze in mould spring .your inquiries will get prompt reponse

within 24 hours.

3.Free design all kind of non-standard mould spring as you requested.

4.Specification: 6X10mm ---70X500mm

5.Paint:environmental protection electrophore

Mould Spring:Use of attention for mould spring

Choose right mould spring or will distortion and reduce service life.

Can’t have gap between upper plate and mould spring or will distortion and rupture.

When free length of moudl spring is 4 times to outer diameter ,please use guide rod shield to protect service life.

Can't use it for anything except compression .

Please use it on the mould.

When the lower plate parallelism is not well, high stress will happen and cause transformation and rupture .

It must be have some preloading when put mould spring on the mould . preventing mould Bear impact load and cause fatigue damage.

Install and valid service condition

>When Coil Spring install the hole of bottom without leader ,the deep of hole must be more than two rings than mould springs.

>when mould spring install with leader ,length of leader must be higher than length of mould spring

>.Close state (stroke limit) is reference dimension ,Pls do not use if more than 300000 times or it will be bending and failure.

>When installing, preloading is one over ten or more of the compression. When cope plate use with gap .will cause mould spring bending or scrap.

Service condition:

1. Allowed temperature range for mould spring

TF.TL.TM.TH.TB.TR.TY : 80°C--30°C

Higher than these temperature ,you should customize.

In practice,when temperature higher than above. Mould spring will be scrap ,bending and etc. or use based on technicist’s guide .

2.Don’t use mould spring on high temperature and wet ,or mould spring will be scrap ,bending and rustiness.

Packaging and Transportation

Our factory of Mould Springs

- Q: The glass door spring is generally guaranteed for several years

- Quality and price are pretty much the same. Many other miscellaneous brands of spring can be guaranteed for five years, three years it is best to begin with a reliable brand

- Q: Want to practice how to use pectoral muscle spring expander

- Every day until the last time I can not pull itFull pullExercise is a long process

- Q: Stainless steel and spring steel hardness, who is hard?

- Hardness is checked by indentation, not by pliers.Stainless steel, of course

- Q: What is flat steel? Plain carbon flat steel? Spring flat steel

- Flat refers to the width 12-300mm, thickness 4-60mm, cross section is rectangular in shape and with a blunt edge of steel. Plain carbon flat steel refers to carbon content of 0.06-0.22% flat steel. The spring flat steel refers to the flat steel with good elastic deformation ability.Flat steel can be finished steel, or can be used as the blank of welded pipe and thin slab for laminated sheet rolling. Main application: flat steel is used as a material, used for making iron, tools and machinery parts, and used as frame structures and escalators for buildings.

- Q: I buy a spring made of 1.2mm steel wire from a hardware store that needs quenching

- The quenching temperature of the spring depends on the critical temperature of the spring material. After quenching, there should be no free ferrite and cementite in the metallographic structure of the spring material, so as not to lead to uneven deformation or fatigue strength. When quenching, the oxidation and decarburization shall be prevented as much as possible.

- Q: What is an independent bagged spring?

- Independent bags, spring inner bladder, column spring, non-woven fabric wrapped, unique ultra quiet design, for you and your sleeping partner to create a warm sleep atmosphere.Independent bagged spring bladder, designed and manufactured by leading domestic production line, fully conforms to the Qi curve formed when maintaining human body sleep. Straight cylindrical spring, non-woven separated, effectively avoid the metal liner due to friction also belongs to the voice with humanization ultra quiet design, to create a warm atmosphere for you to sleep, and when you sleep with the move will not give you his lying position caused by any vibration, so as to ensure the quality of your sleep. Straight cylinder liner using the circular shaped spring, with extraordinary comfort and elastic stability.

- Q: Is the car short spring good?

- Hello: no modification is recommended! Although the spring shortening can reduce the height of the body to make the car appear more sporty, it can also reduce partial roll during cornering. But it does more harm than good. Below say, change the disadvantage of short reed. First of all, lowering the body will affect the passing, and the over speed belt is easy to drag the chassis. Another major drawback is that the full set of shock absorbers consists of a helical spring and a hydraulic cylinder shock absorber.

- Q: How about the size of the elasticity?

- Stretch by the object, extrusion and elastic deformation, the elastic solution is to look at the state of the object, at rest or in uniform linear motion of an object according to the stress analysis of the relationship between the force and other force, curve movement or acceleration force balance objects can analyze the stress in Newton's second law for, no matter what type of stretch can use the two methods to solve the hope to adopt: -)

- Q: In short, in vibration and wave, it is not easy to make mistakes when we grasp the difference and relationship between "displacement" and "displacement relative to the balance position"

- In short, in vibration and wave, it is not easy to make mistakes when we grasp the difference and relationship between "displacement" and "displacement relative to the balance position"

- Q: The glass door spring is broken. How much would it cost to change it?

- The ground springs are not expensive, they are artificially expensive. It won't cost more than 300 yuan, depending on where you are. For example, 180-220 people will do it in the county. In the township, then you do not want to do aluminum alloy will not exceed 200

1. Manufacturer Overview

| Location | Suzhou, China |

| Year Established | 2001 |

| Annual Output Value | more than US$ 5 Million |

| Main Markets | North America, South America, Eastern Europe, Southeast Asia, Africa, Mid East, Eastern Asia, Western Europe |

| Company Certifications | ISO/TS 16949; ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | About 170 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | About 35,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Mould Spring with free design

- Loading Port:

- Ning Bo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000Pieces pc

- Supply Capability:

- 100000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords