Torsion Spring, long-service life

- Loading Port:

- Nansha

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5T pc

- Supply Capability:

- 151000000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features of Torsion Spring:

1) Dimensions:

a) Wire diameter: 0.15 ~ 65mm

b) Thickness: 0.15 ~ 20mm

2) Long service-life

3) Good hardness

4) Good resistance to both high and low temperatures

5) Can be used in various corrosive mediums

6) Main material: carbon spring steel, alloy spring steel,

refractory steel, stainless steel, high temperature

resisting alloy, corrosion-resistant alloy and bronze

7) Widely used in automobiles, motorcycles, electrical

appliances, telecommunication, communication,

aviation, space and other civil fields

Inner packing: plastic or PE bags

Outer packing: corrugated cartons, wooden boxes or pallets

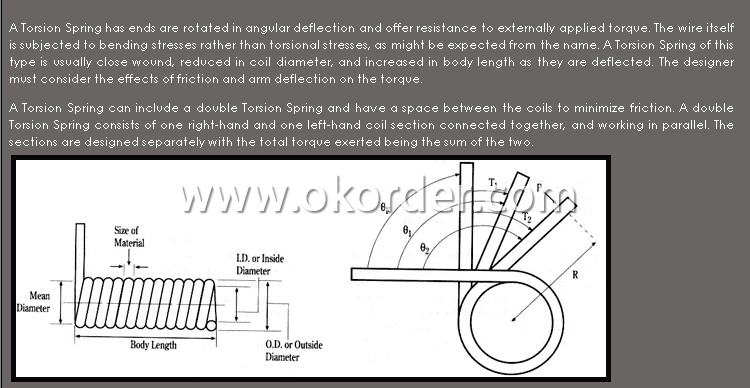

How the torsion springs work?

Packaging Of Our Products

- Q: Spring dynamometer and spring balance what is the difference

- The principle is similar, but the uses are somewhat different

- Q: What's the manganese content of spring steel?

- Alloy spring steelAlloy spring steel is based on carbon steel, by properly adding one or more alloying elements to improve the mechanical properties, hardenability and other properties of the steel, to meet the requirements of the manufacture of various springs of steel.The basic composition of series alloy spring steel, spring steel, silicon manganese chromium chromium manganese spring steel, spring steel, spring steel, chromium vanadium tungsten chromium vanadium spring steel. On the basis of these series, some brands added alloying elements such as molybdenum, vanadium or boron in order to improve their performance in some aspects.In addition, other grades of steel, such as quality carbon structural steel, carbon tool steel, high speed tool steel and stainless steel, are selected as spring steel.

- Q: How to choose spring steel material?

- In determining the cross-section shape and size of spring materials, priority should be given to rejection of the national standards or ministerial standards for size specifications, as far as possible to avoid the use of non-standard specifications of materials. Although the spiral spring square or rectangular cross section material, the elastic deformation can be higher than, can make the small volume of the spring, for spring, in small space or under impact load but because of square or rectangular section material shortage, the price is higher, and the spring forming is difficult, so should be avoided. Ring section spring material diameter series see table 3-9.

- Q: What kind of spring has the best performance?

- Spring verticality, verticality is bad, will directly affect the strength and life.

- Q: The shop glass spring door is too tight, how to adjust?

- It is better to ask professionals to deal with the danger!

- Q: Cold rolled coil spring spring and difference "

- Coil is to burn the red, generally large diameter to coil

- Q: Is the car short spring good?

- Hello: no modification is recommended! Although the spring shortening can reduce the height of the body to make the car appear more sporty, it can also reduce partial roll during cornering. But it does more harm than good. Below say, change the disadvantage of short reed. First of all, lowering the body will affect the passing, and the over speed belt is easy to drag the chassis. Another major drawback is that the full set of shock absorbers consists of a helical spring and a hydraulic cylinder shock absorber.

- Q: How about the size of the elasticity?

- The force is analyzed and the force is decomposed along the positive plane and its vertical direction

- Q: What are the main functions of spring?

- There are many kinds of spring, and the spring is mainly divided into four kinds: stretching spring, compression spring, torsion spring and bent spring. If in accordance with the spring shape and can be divided into helical springs, disc springs, ring spring, plate spring, spring etc.. The basic types of springs are listed in the table. Air springs.

- Q: Physics high school. Why does a spring fall to the lowest point and the acceleration a must be greater than the acceleration of gravity g ah. Seek expert

- For small spheres, the energy is conserved from the free fall to the ultimate spring compression equal to the maximum value of XMgX=0.5kX^2 (this formula is obtained by integration, do not know if you have no calculus)Calculate X=2mg/k, then the lowest point is the resultant force of the ball is kX-mg=2mg-mg=mg, in the direction of acceleration, the size is exactly equal to GIf the ball is considered to fall from high, then the energy conservation before it converts the energy of the potential energy into springs is naturally more, and the acceleration of the lowest point ball is greater than g

1. Manufacturer Overview

| Location | Suzhou, China |

| Year Established | 2001 |

| Annual Output Value | more than US$ 5 Million |

| Main Markets | North America, South America, Eastern Europe, Southeast Asia, Africa, Mid East, Eastern Asia, Western Europe |

| Company Certifications | ISO/TS 16949; ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | About 170 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | About 35,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Torsion Spring, long-service life

- Loading Port:

- Nansha

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5T pc

- Supply Capability:

- 151000000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords