TP8-200A Rotary Packing Machine automatic

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Descriptions of TP8-200A Rotary Packing Machine

TP-TGXG-200 Bottle Capping Machine is an automatic capping machine to press and screw lids on bottles. It’s special designed for automatic packing line. Different to traditional intermittent type capping machine, this machine is a continuous capping type. Compared to intermittent capping, this machine is more efficient, pressing more tightly, and do less harm to the lids. Now it’s widely applied in food, pharmaceutical, chemical industries. It consists of two parts: capping part and lid feeding part. It works as following: Bottles coming(can joint with auto packing line)→Convey→Separate bottles in same distance→Lift lids→Put on lids→Screw and press lids→Collect bottles.

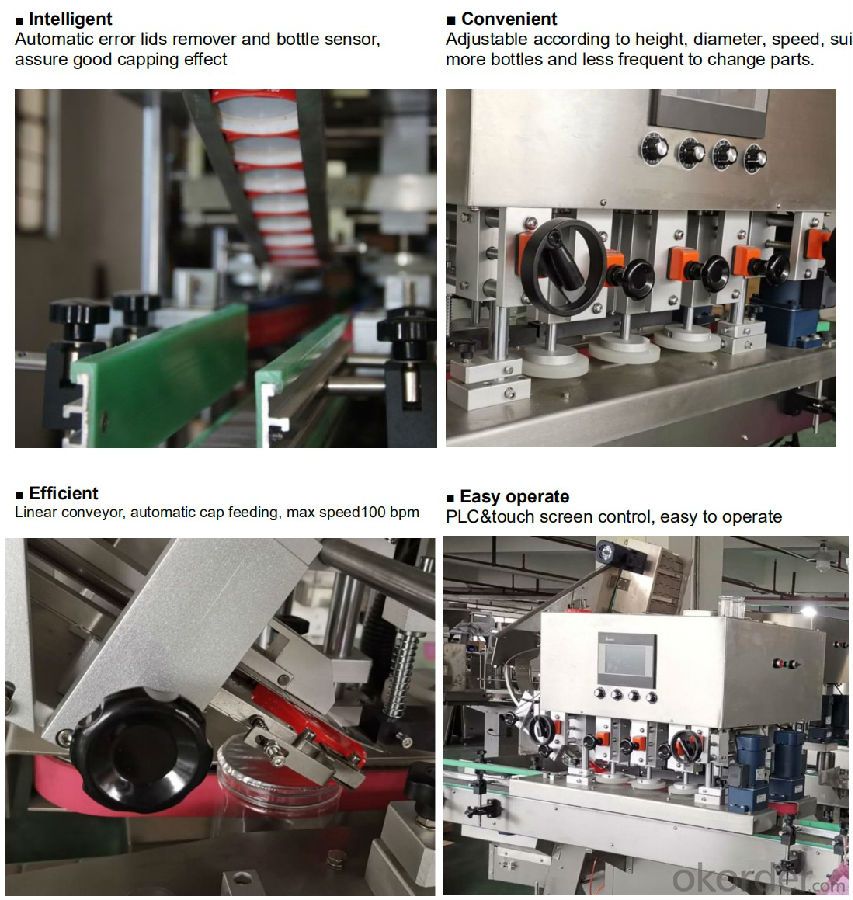

2. Main features

- PLC&touch screen control, easy to operate

- Easy to operate , Speed of conveying belt is adjustable to synchronous with whole system

- Stepped lifting device to feed in lids automatically

- Lid falling part can remove error lids away(by air blowing and weight measuring)

- All the contact parts with bottle and lids are made of material safety for food

- The belt to press the lids is inclined, so it can adjust the lid into the correct place and then pressing

- Machine body is made of SUS 304, meet GMP standard

- Optronic sensor to remove the bottles which are error capped (Option)

- Digital display screen to show the size of different bottle, which will be convenient for changing bottle(Option).

3. Technical parameters

| TP-TGXG-200 Bottle capping machine | |||

| Capacity | 50-120 bottles/min | Dimension | 2100*900*1800mm |

| Bottles diameter | φ22-120mm(customized according to requirement) | Bottles height | 60-280mm(customized according to requirement) |

| Lid size | φ15-120mm | Net weight | 350kg |

| Qualified rate | ≥99% | Power | 1300W |

| Material | Stainless Steel 304 | Voltage | 220V/50-60Hz ( or customized) |

4. Detailed photos

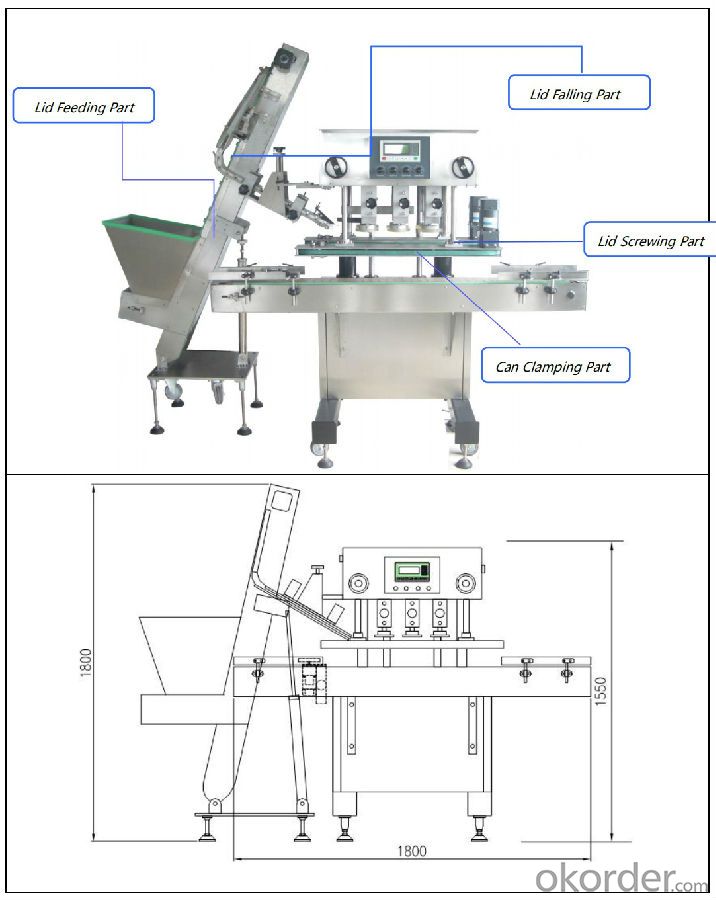

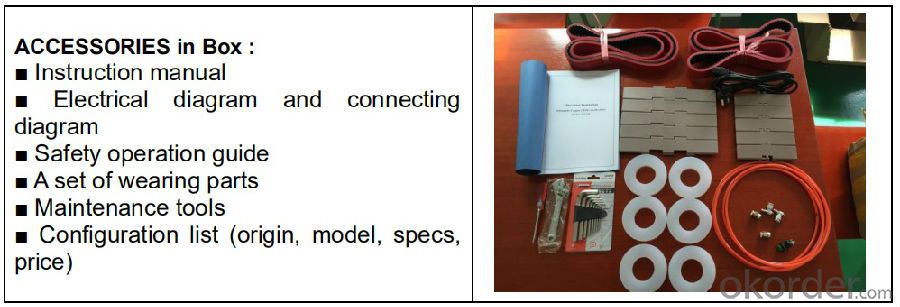

5. Structure & Drawing

6. Shippment & Packaging

- Q: What is the design basis of automated packaging?! Just for today!

- Greatly improve the degree of automation of process flowA few years ago, automation technology accounted for only 30% of the design of packaging machinery, now has accounted for more than 50%, a large number of micro computer design and mechanical and electrical integration control. To improve the packaging machinery automation, one is to increase productivity; the two is to improve the flexibility and agility equipment; three is to improve the ability of packaging machinery to complete the complex action, namely the manipulator to complete the packaging process. Such as chocolate packaging has been achieved, with mechanical hand instead of the original manual. Automatic design of packaging machinery has the following two main characteristics:

- Q: Ask a mechanical problem, the waste film recycling in the packaging machinery is a new film packaging, after cutting, then use the roller to recycle the waste film. Encounter a

- It's a good mechanical design problem! In principle, yes, for example, to achieve the rated torque of the motor. He'll stop by himself! What isn't that great torque? You can zoom in on the load torque

- Q: What is the price of a small jujube packing machine?

- Mainly see what some requirements, automatic metering packaging or vacuum packaging machine, after understanding can determine the price.

- Q: Packaging machine knife cut out of the mouth is uneven, always inclined, so adjust, now tune not come back, or is unable to cut off, or die!

- Change a new one, in fact, the knife is very simple, and the ordinary knife is very cheap.If you don't understand, you can ask me

- Q: What machine does the packing carton machine have?

- Since its establishment, the company has continued to provide specialized packaging equipment and transportation equipment for domestic first-class enterprises, as well as perfect solutions for automated transportation systems.

- Q: The role of packaging equipment in packaging equipment

- (4) it can reduce labor intensity and improve working conditionsThe labor intensity of manual packaging, such as volume, weight heavy manual packaging products, both the consumption of physical strength, and safety; and for small and light products, due to high frequency, easy to make the action monotonous, worker occupation disease.(5) labor protection for workersFor some serious impact on health products, such as serious dust, toxic products, irritating, radioactive products, manual packaging is a health hazard, and packaging machinery can be avoided, and can effectively protect the environment from being polluted.(6) it can reduce the packing cost and save the storage and transportation expensesFor loose products, such as cotton, tobacco, silk and hemp, the compression packing machine can reduce the volume and reduce the packing cost. At the same time, due to the reduction of large volume, in order to save storage capacity, reduce storage costs, is conducive to the transport.

- Q: Working principle of packing machine

- The working principle of the packing machine is simple. The packing material is first installed on the packing machine and installed

- Q: What's the best place to use the pillow type packing machine?

- Suggest that manufacturers can find communication, there is no technical strength,

- Q: What does that mean when the composite material is pressed and molded? What are pressing forming? What are the characteristics of press molding equipment? Its development

- Can be used to shape complex products. The principle is similar to that of injection molding. One is used for thermosetting, heating and cooling in molds, one for thermoplastic, and the other for heating in the barrel and molding cooling in the mold.

- Q: Energy saving reform of packaging machine

- Due to the adoption of variable frequency speed regulation, the chain drive is greatly reduced, the stability and reliability of the operation of the machine are improved, and the noise of the machine operation is reduced. It guarantees the high efficiency, low loss and automatic detection of the packaging machine. It has both a beautiful and fashionable appearance, and a healthy and smart mind.Although the transmission system used in food packaging machine is relatively simple, it has higher requirements for the dynamic performance of the transmission. The system requires fast dynamic follow-up performance and high stability speed accuracy. Therefore, we must consider the dynamic technical indicators of inverters, and select high-performance inverter to meet the requirements.

Send your message to us

TP8-200A Rotary Packing Machine automatic

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords