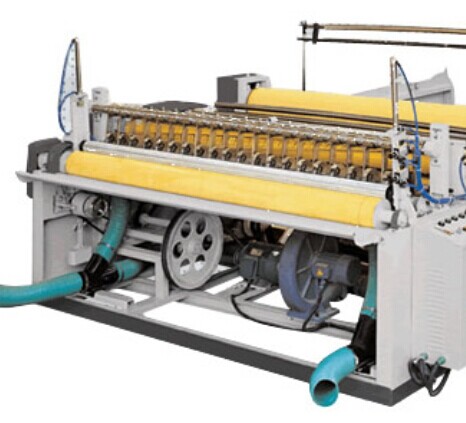

Toilet Paper Slitting Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

I. Introduction

Model name: DC-RSM-1092/1575I

This machine is used to produce the small rolls of tissues as the picture shown above.

II. Function and Features

DC-RSM-1575I Automatic Rewinding and Slitting Machine is designed to convert the big jumbo roll into finished industrial roll which is used in public toilet or workshop and garage for cleaning. This equipment has the feature of tight structure, easy and stable operation, It is a suitable choice for small to middle scale toilet roll converter.

III. Technology Parameter

1.Original Jumbo Roll Specification: diameter: 1100, Max width: 1750 (mm)

2.Finished products specification: Diameter 400, width: 80~1750(mm)

3. Production Capacity: 180-200 m/min

4. Perforation line distance: 100-150mm(can be adjusted)

5.Jumbo rolls stands:2 plys

6.Power: 4Kw, 380V, 50HZ (For your reference, it depends on the power situation in your place)

7. Outside Dimension: 6200×2600×1800 (mm) (L×W×H)

8. Weight: 3T

IV. Export Details

1. Delivery time: 30 days (It takes time to ensure the processing precision, assembling precision, etc. Of course, the delivery time can be discussed as the case may be.)

2. Load port: Xiamen port in Fujian Province

3. Packing: In standard export wooden cases

4. Container: 1 x 20 feet container (It depends on the quantity of the machines you buy ).

5. Machine installation and operation training: The seller should dispatch professional technicians and engineers to buyer’s plant to install the machine and train the workers. The round air ticket, accommodation and salary should be paid by buyer.

6. Warranty period: One year(Except easy damaged parts), and will provide long term services including providing spare parts at low price and will heart and soul help the buyer to solve any problem may occur.

7. Our company also provides the raw material to match with the machine.

- Q: Predecessors please point out: what is the future of packaging machinery industry?

- China's packaging machinery and equipment manufacturing enterprises should seize this opportunity.The overall upgrading of packaging machinery equipment is the general trend of the development of packaging machinery in China and the world. The main features of the renewal is: a large number of transplanted with civilian and military industries all modern high precision technology and electronic technology, microelectronic technology, edge technology, fuzzy technology, accelerate the further improve the reliability, safety, no work of the level of automation of packaging machinery and equipment and production line. Intelligence will move into the field of packaging machinery, equipment and production lines.

- Q: What kind of reducer is commonly used in packaging machinery?

- There are many kinds of packing equipment, such as food packing, filling, quantitative packing, back channel packing and so on

- Q: What's the best place to use the pillow type packing machine?

- Suggest that manufacturers can find communication, there is no technical strength,

- Q: How much is the tableware wrapping machine?What's the price of the tableware wrapping machine?

- Tableware packing machine? Should the packing of the tableware be contracted? Tak Cheung packing machinery, automatic heat shrinkable tableware packing machine can be considered

- Q: How is the production and characteristics of ceramic wall tiles different from the size and performance of molding?

- What is the size of the parison forming pressure and the performance of the ceramic wall and floor tile products?Ceramic wall and floor tiles are usually formed by pressing. Domestic made for 30 tons, imported equipment has tons of suppression, 200 tons and 500 tons. In order to smooth accurate size, excellent products, must pay attention to the effect of powder properties and compression of products. That is to say, the quality of the floor tiles, billets, methods of preparation, and the quality of products and production scale and way of pressing machinery. As for pressing pressure, as the molding pressure decreases, the sintering shrinkage becomes smaller and the water absorption rate becomes smaller, the durability of the product should be improved. It should be noted that the pressure should not be too high. Excessive pressure, stress, and density increase will cause unnecessary energy consumption, and cause compressed air to expand after pressure is canceled and cause excessive spalling.

- Q: Is there anyone who knows what groups of users of packaging machinery are in general?

- If automated packaging, it depends on the factory situation, should not be from the user groups to start. If a small class of cosmetics do, then he will not say to buy a more than ten thousand or hundreds of thousands of automated equipment to pack ah. Automatic packing machine is certainly need a certain amount, a certain basis will be needed, or buy a mechanical automation a month the amount of packaging takes less than one hour, then buy this station automation machinery to do what? So, according to the automatic device, we can not start from the user groups, should be considered from the size of the factory.

- Q: What are the packaging machines that use temperature control watches?

- Such as shrink machine, vertical packaging machine, pillow type packaging machine, continuous sealing machine,

- Q: What is a packaging machine?

- Well, before and after the associated processes, such as cleaning, stacking and disassembly. In addition, the package also includes the measurement or in the processes of stamp packages. Mechanical packaging products can improve productivity, reduce labor intensity

- Q: Food, equipment, tools, containers, packaging materials, etc. shall comply with food safety standards or requirements

- Hygienic standard for polyethylene terephthalate resin for GB 13114 food containers and packaging materialsGB, 13113-1991. Hygienic standard for polyethylene terephthalate molded articles for food containers and packaging materials

- Q: Will the Internet be too passive? Telephone marketing, what kind of food can be found in the factory, such as the phone, people basically do not need, and all have. Does the salesman run the market? How do you run? Thanks for the direction...

- Ha ha, as you say, TV factories are closed down, every household has a TV, but every day there will be a lot of people buy tv.

Send your message to us

Toilet Paper Slitting Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords