Tire for Mining truck mining loader SUPER ROCK, mine tyre 23.5R25 loader tire with quality warranty

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 watt

- Supply Capability:

- 100 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SUPER TIRE CATALOG --RDT

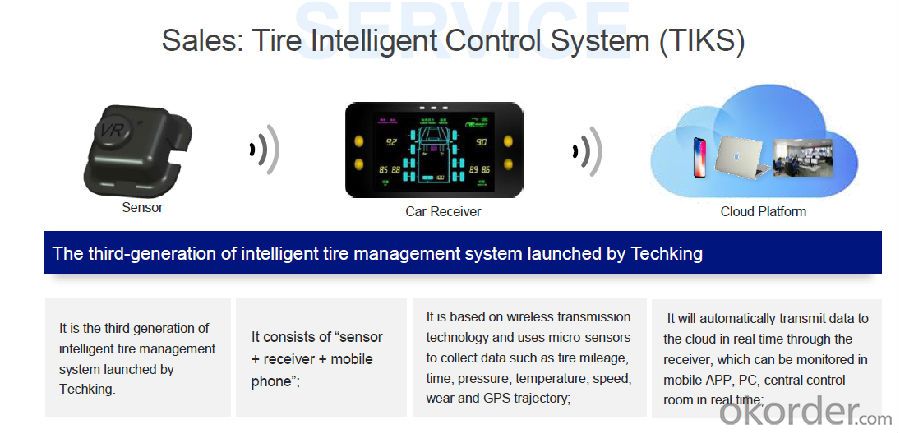

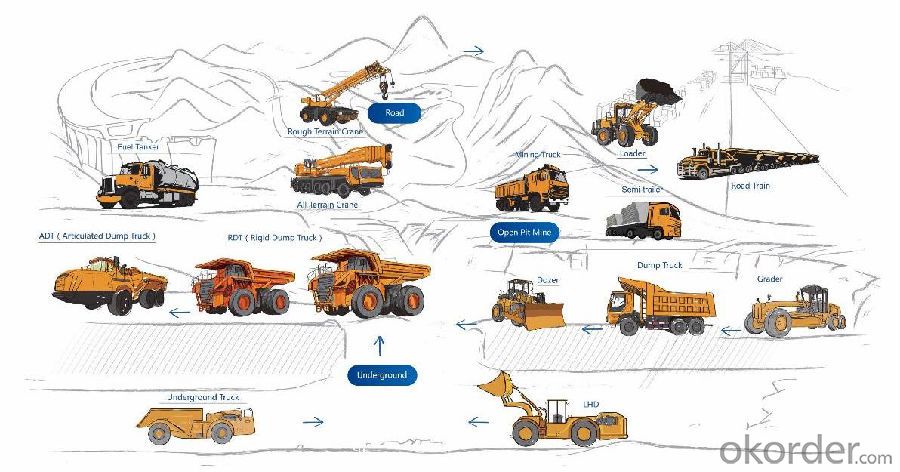

We provide customers with all-round tire management, from pre-sales pattern selection to after-sales tracking service, to reduce operating costs for customers.

CASE SHOW

SUPER ETOT Tires Run Well in a Coal Mine in Inner Mongolia

In May 2019, service team visited an open-pit coal mine located in Erdos, Inner Mongolia, China.

There are more than 100 units of dump truck working in this coal mine with 2 shifts (2*10hrs). SUPER ETOT 14.00R 24/25 has been used in the mine since this January. The total weight of the dump truck could be up to 100 tons (loading capacity is 50-60 tons), which is a big challenge for the

tires. The on-site fleet leader told us that tire quality is so good that they never had tread separation problems. Our team estimated the average life of SUPER ETOT 14.00R 24/25 could reach about 6-7 months which is 1-2 month longer than the other brands.

If you want to get more information please contact me.

OTR Field Reports 2019-2020

[PR]-14.00R24 ETOT in China-20191119

[PR]-14.00R24 SUPER ETOT in China-20190910

[PR]-16.00R25 ETRTV in Balkan Peninsula-20190729

[PR]-18.00R25 ETSM, 26.5R25 ETSM, 26.5R25 ETNT in Zambia-20190628

[PR]-18.00R25 PROLHD in China-20190731

[PR]-18.00R25 PROLHD, 17.5R25 ETSM, 18.00R25 ETSM in Morocco-20200125

[PR]-18.00R33 ETDT in Portugal-20190722

[PR]-24.00R35 ETDT in Indonesia-20191028

[PR]-24.00R35 FORT RDT and 18.00R33 ETDT2 in Jordan-20190821

[PR]-24.00R35 FORT RDT in South Korea-20191210

[PR]-24.00R35 SUPER RDT in Russia-20200225

[PR]-24.00R35 SUPER RDT in Russia-20191029

[PR]-24.00R35 SUPER RDT in Russia-20191204

[PR]-24.00R35 SUPER RDT in Russia-20200213

[PR]-24.00R35 SUPRE RDT and ETDT in Russia-20190905

[PR]-26.5R25 ET6A in Russia-20191112

[PR]-27.00R49 ET304 and 27.00R49 SUPER ROCK in South Africa-20191015

[PR]-27.00R49 ET304 in Russia-20190918

[PR]-27.00R49 ET304 in Russia-20191205

[PR]-27.00R49 ET304 in South Africa-20190624

[PR]-27.00R49 ET355 in Papua New Guinea-20190710

[PR]-27.00R49 SUPER ROCK in Russia-20200205

[PR]-27.00R49 SUPER TRAC in Indonesia-20190923

[PR]-29.5R25 ETADT in Malaysia-20200106

[PR]-29.5R25 FORT ADT in Ghana-20190923

[PR]-29.5R25 PROADT, 26.5R25 MATE E3L3, 26.5R25 ETDL in Egypt-20191125

[PR]-29.5R25 SUPER ADT in Israel-20200115

[PR]-29.5R25 SUPER ADT in South Korea-20200129

[PR]-29.5R29 ETSM in Australia-20190723

[PR]-33.00R51 ET304 in Russia-20191105

[PR]-35x65R33 ETDL5 in Mexico-20190715

[PR]-35x65R33 ETNT 4 in Australia-20190923

[PR]-40.00R57 ET304 in Canada-20191009

[PR]-40.00R57 ET304 in Uzbekistan-20191209

- Q: What spare parts does mine machinery equipment have?

- My company with good products, reliable reputation, reasonable prices and warm service, is willing to work with you sincere cooperation, hand in hand, and pioneering and innovative, and seek common development!

- Q: What are the common faults of tower cranes? Removal method

- 1., the tail thread and withdrawal groove, hook surface cracks2. hook dangerous section wear3., hook and bending parts of permanent deformation

- Q: China's most powerful mine wear parts

- Wear parts, usually wear plate processing, such as JFE-C400, JFE-C500, DILLIDUR 400V and other imported wear-resistant plate processing parts, long service life, than ordinary wear parts is about ten times higher.

- Q: What are the accessories for mining machinery?

- Bearings, screens for vibrating screens, belts for belts, etc.!! A lot of ah, these are worn parts, what's the problem, ask me again, see the signature on the phone

- Q: What are the accessories for mining machinery?! Mainly refers to?

- Pick, pick, pick coal mine, shearer, boring machine, cutter knife type cutter, diamond drill, drill bits, coal, wind, anchor drill drill bit, drill, bolt, cross wind wind coal drill pipe, drill pipe, drill pipe, spiral pipe, dry coal mine machinery drilling accessories, etc..

- Q: How to do the maintenance of mining machinery parts?

- Reduce the influence of mechanical impuritiesMechanical impurities are generally referred to as dust, soil and other non-metallic materials and mining machinery in the process of its own production of a number of metal debris, wear products, etc.. Once these impurities into the internal machinery to match surface mechanical, its harm is great, not only make out the relative motion block, accelerated wear parts, and will scratch with the surface, destruction of the lubricant film, make parts temperature and oil deterioration.For the mining machinery work in harsh environment and complex condition places, one is to use high quality, supporting components and lubricating oil and grease, the source block harmful impurities; two to do a good job of mechanical protection work site, ensure the corresponding mechanism to work, to prevent the impurities from entering the internal machinery. For failure of machinery, as far as possible to the formal repair site repair. Site repair, but also to do a good job of protection measures to prevent on-site repair parts replaced by dust and other impurities before entering the machinery.

- Q: I would like to ask the general mine machinery industry, the purchase of accessories must not go to the original factory to buy?

- Not necessarily, it is best to buy the original factory, after all, they are supporting the production of it!

Send your message to us

Tire for Mining truck mining loader SUPER ROCK, mine tyre 23.5R25 loader tire with quality warranty

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 watt

- Supply Capability:

- 100 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords