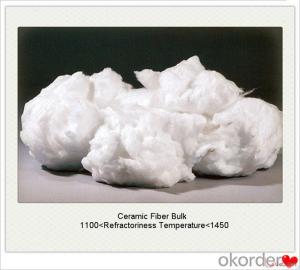

Ceramic Fiber Bulk - Thermal Insulation Chopped Wool Pure White

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Thermal Insulation Ceramic Fiber Chopped Bulk CCE WOOL Pure White

| Place of Origin: | China (Mainland) | Brand Name: | Model Number: | Thermal Insulation Loose Ceramic Fiber Bulk | |

| Application: | raw material | Grade: | COM (Common) | Working Temperature: | 950 ℃ |

| Fiber Diameter: | 3-5 μm | Thermal Conductivity: | 0.6 w/m.k | Shrinkage (1800℉, 3h): | -3% |

| density: | 2.73g/cm3 | slag content (diameter>=0.212mm): | <=22%< span=""> | chemical composition: | Al2O3+SiO2 (%)>=97% |

| color: | pure white | packing: | woven bags | certificate: | ISO 9001, CE, REACH |

Packaging & Delivery

| Packaging Details: | woven bags |

| Delivery Detail: | within 15 days after received the deposit |

Characteristics

*Good springiness for fiber

*Excellent strength and resistance to blowing

*Excellent chemical stability, resistance to erosion

*Low thermal conductivity

*Low thermal shrinkage

*Excellent sound absorption

Typical Applications

*Filling insulation and joint sealing

*Back-up lining for industrial furnaces

*Fireproof materials for construction

*High temperature materials for filtration

*Raw materials for further producing, such as modules

Product Description forInsulation Ceramic Fiber Spun Bulk

Ceramic chopped fiber bulk is made by chopping the ceramic fiber spun bulk, it is an ideal material for making ceramic fiber board and vacuum formed ceramic fiber shapes.

Characteristics:

Low heat capacity and low thermal conductivity;

Excellent chemical stability;

Excellent thermal stability, resistance to pulverization at high temperature;

With no binders or corrosive substances;

Excellent sound absorption

Typical Application:

Raw material for fiber blanket, board products;

Raw material for fiber textile products;

Fillings for wall lining gap in high temperature furnace, heating device;

Raw material wet processed products;

Fiber spraying;

Castables;

Raw material for coatings;

Insulation fillings for corner and complex space

Technical data for Ceramic fiber Bulk

Properties | Unit | 1260 Bulk | 1425 Bulk | 1500 Bulk | 1600 Bulk |

Classification Temperature | °C | 1260 | 1425 | 1500 | 1600 |

Room Temperature Properties(23°C/Relative Humidity 50%) | |||||

Color | White | White | Green | White | |

Density | g/cm³ | 2.70 | 2.70 | 2.70 | 3.2 |

Melting Point | °C | 1760 | 1760 | 1760 | - |

Average Diameter for Fiber | μm | 2.8 | 2.8 | 2.8 | 3.1 |

Chemical Compositions | |||||

Al2O3 | % | 44-48 | 34-36 | 43 | 72 |

SiO2 | % | 52-56 | 48-50 | 54 | 28 |

ZrO2 | % | - | 15-17 | - | - |

Cr2O3 | % | - | - | 3 | - |

FAQ:

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. Can you give me a general idea of the specification and technical data of your products?

Yes, catalog is on your request.

3. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

4. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc.

If any question, please contact us freely.

- Q: What are the main differences between an ordinary furnace and a ceramic fiber furnace?

- The main difference between ordinary furnace and ceramic fiber furnace:Refractory, heat insulation: ceramic fiber furnace low thermal conductivity, low thermal conductivity, is a better thermal insulation materials, the use of temperature within one thousand and three hundred Baidu. The heat conductivity of common furnace is higher and the heat loss is great

- Q: What is the density of ceramic fiber modules? The best insulation effect

- Ceramic fiber module density is only a standard in the world, is 220Kg/m fand, but in the actual application, according to the heat treatment furnace, furnace temperature, combustion medium, temperature rise requirement of ceramic fiber module density in 200-240Kg/m fand, ceramic fiber blanket, because the processing of ceramic fiber module uses double roller today advanced technology and technology of silk, fiber length of the ceramic fiber blanket which produced in 80-130 mm, so the maximum density of the ceramic fiber module is more than the density, 240Kg/m fand, a large amount of fiber fracture, the fracture rate is as high as 48%. So after the actual verification at home and abroad of tens of thousands of industrial furnaces, the best density of ceramic fiber module is fand 220Kg/m.

- Q: Should the ceramic fiber furnace be compacted?

- The simplest, the least durable method, uses ceramic fiber blankets for wrapping, which is often caused by the poor density of the ceramic fiber blanket and the lack of anchorage

- Q: What is the difference between the ceramic fiber cloth and the high silicon oxygen cloth?

- Ceramic fiber is a short fiber that needs to be reinforced and toughened by other objects. It is generally toughened by glass fiber and stainless steel wire. The high silicon oxygen is long fiber, no need to toughen by other objects. The short-time high silica resistance to high temperature, Suzhou Dexin ceramic high silica cloth of silica content is greater than or equal to 96% temperature up to 1700 DEG C.

- Q: Aluminum silicate ceramic fiber cotton smoke will cause pneumoconiosis?

- 1, general masks, gauze, masks, etc., can not be used as dust masks.2, mask must pass GB 2626-2006 standard certification.3, it is recommended to choose N100 class dust masks.4, individual suggestions according to choose different shapes masks.5, it is recommended to change the filter gauze mask. Material recommended for silicone material.Through the above way, it can effectively prevent pneumoconiosis.

- Q: What is the diameter of the ceramic fiber? How to mix?

- Fiber diameter: rejection fiber more coarse, rejection fiber generally 3.0-5.0 - m, spinneret fiber is generally 2.0-3.0 - m;

- Q: Is aluminum silicate fiber poisonous?

- Then use the compressed air jet or use the wire throwing machine to turn the yarn into a fiber. After the cotton collector sets the cotton, it forms the ceramic fiber cotton. In the whole process of production, it can be found that the raw material does not contain toxic substances. Compared with asbestos, it is a substitute product of asbestos and contains no carcinogens.

- Q: What is the good heat insulation effect of glass fiber and aluminum silicate fiber, what are their respective advantages and disadvantages?

- Adiabatic effect: glass fiber thermal conductivity at room temperature was about 0.056, the thermal conductivity at room temperature is about 0.035, due to the lower thermal conductivity, moisturizing effect is better, so the material characteristics of aluminum silicate fiber insulation effect is good, but also with the insulation effect of fiber compression density, can not be generalized.

- Q: Aluminum silicate needle carpet and ceramic fiber insulation performance of the good

- Aluminum silicate needle carpet should be aluminum silicate needled blanket, with the continuous production, by acupuncture fiber uniformity, high tensile strength, does not contain any additives. Ceramic fiber, also known as aluminum silicate fiber, is only a different name.

- Q: Ceramic fiber material fire shutter door how many square?

- If the above two kinds of roller blinds, really true to do, the former per square meter at least 500 yuan, and the latter at least 400 yuan per square meter. Otherwise, there must be a problem.

Send your message to us

Ceramic Fiber Bulk - Thermal Insulation Chopped Wool Pure White

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords