The Best 3 Packaging Tape - Green PE Stretch Film 50Micron Self Adhesive

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

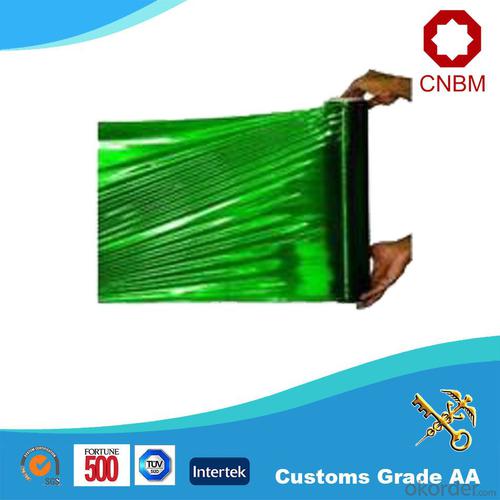

Green PE Stretch Film 50micron Self Adhesive

Product Description

Stretch Film is a highly stretchable plastic film that is wrapped around items. The elastic recovery keeps the items tightly bound. In contrast, shrink wrap is applied loosely around an item and shrinks tightly with heat.

It is frequently used to unitize pallet loads but also may be used for bundling smaller items.

FEATURES:

Excellent in adhesion and flame retardant

Resistance to cold, heat and aging.

High Temperature stability

High mechanical strength and good impact resistance

Ideal for use in dispensers

Printable

Data Sheet

Width | 100mm-720mm |

Thickness (micron) | 15-35 |

Color | Transparent and Colored |

Angle Tear Strength (N/mm) | 120 |

Tensile Strength (Mpa) | 39 |

Elongation at break (%) | 300,600 |

Impact Ability or Pendulum | 0.15 J/mm |

Tackness (N/cm) | 3 |

Light Transmission Rate (%≥) | 92 |

Frog Density %≤ | 2.5 |

Packing | Carton |

Delivery | With 10-25days after receiving deposit |

Payment | T/T & LC |

Authorized Certificate

Production Line

Exhibition Domestic and Oversea

Company

China National Building Materials Group is a state-owned company. As World Top 500 companies, we have clients from over 160 countries and wholly-owned overseas subsidiaries and branches in 10 countries. We supply adhesive tape for over 20 years.

We supply various strech film. All our products have been SGS and ISO9001 certified and exported with Grade AA approval. The quality and performance all meet the advanced international levels.

FAQ

1. Why choose us?

20 Years Experience USD1.6 billion yearly sales

World Top 500 Enterprise

OEM service, supported by strong R&D team

A short lead time

Quality guarantee with third party certification

One-step service: transportation, capital etc.

2. What can we do for you?

Professional consultation on your local market

Custom-made advices for your need

Free samples of Stretch Film

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Satisfactory sales service

3. Delivery time

7-25 days after receiving the deposit

4. Packing and Shipping

36 Rolls per Caron.

5. What is other specifications of adhesive tapes?

Bopp Tape: widely used for carton sealing and packaging, light duty packaging, bounding, holding and other office and household use.

PVC Electrical Tape: widely used for insulating, protection and color coding of electrical wires; may also be used as harness tape in automotive industry.

Cloth Tape: widely used for pipe wrapping, gaffers and book binding etc.

- Q: How do I remove packaging tape without damaging the surface?

- To ensure the surface remains undamaged, adhere to these steps for removing packaging tape: 1. Commence by gently heating the tape with a hairdryer set on low. The heat will cause the adhesive to soften, facilitating easier removal. 2. Employ your fingernail or a plastic scraper to delicately lift one corner of the tape. Exercise caution to avoid employing sharp objects that might leave scratches on the surface. 3. Gradually peel the tape back at a 180-degree angle, applying consistent and uniform pressure. If the tape proves resistant, pause and subject it to additional heat to further soften the adhesive. 4. In the event any residue remains, employ rubbing alcohol or a mild adhesive remover. Apply a small amount to a soft cloth and gently rub the residue until it lifts away. 5. Once the tape and residue have been eliminated, cleanse the surface with a mild soap and water solution to eliminate any remaining adhesive or residue. Always remember to test any cleaning solution on a small, inconspicuous area beforehand to ensure it does not cause damage to the surface.

- Q: How does packaging tape perform on high-friction surfaces?

- Packaging tape is designed to adhere to a wide variety of surfaces, including high-friction surfaces. Its performance on high-friction surfaces can vary depending on the specific tape and the nature of the surface. In general, packaging tape is equipped with strong adhesive properties that allow it to stick securely to surfaces, even those with high friction. The adhesive on the tape is formulated to provide excellent tackiness and bonding strength, ensuring that it stays in place and maintains its hold on high-friction surfaces. However, it is important to note that excessive friction or roughness on a surface can potentially affect the tape's adhesion. If the surface is extremely rough or uneven, it may create air pockets or gaps between the tape and the surface, which can compromise its performance. In such cases, it is advisable to prepare the surface properly by cleaning and smoothing it before applying the tape to ensure optimal adhesion. Additionally, the durability of the tape can play a role in its performance on high-friction surfaces. Some packaging tapes are reinforced with fibers or have a thicker construction, making them more resistant to wear and tear caused by friction. These tapes are often recommended for heavy-duty applications or when packaging items that will be subjected to constant rubbing or sliding on high-friction surfaces. Overall, packaging tape is generally well-suited for use on high-friction surfaces. Its adhesive properties, combined with proper surface preparation and selection of a suitable tape, can ensure reliable and long-lasting adhesion, even in challenging conditions.

- Q: Are there different colors of packaging tape?

- In the market, one can find various colors of packaging tape. Although clear is the most commonly used color, there are also options like brown, white, black, and even vibrant choices such as red, blue, green, and yellow. The multiple colors of packaging tape serve different purposes. For instance, brown tape is frequently employed for sealing boxes and packages, white tape is commonly used for labeling or writing on, and colored tapes can be utilized for color-coding or enhancing the appearance of packages. The presence of diverse colors enables individuals and businesses to select the tape that best suits their specific requirements.

- Q: Can packaging tape be used for sealing construction or building materials?

- Indeed, packaging tape possesses the capability to seal construction or building materials. Although it lacks the endurance and strength found in specialized construction tapes, packaging tape can serve as a temporary or expedient remedy for sealing materials like cardboard, plastic sheets, or lightweight panels. It is suitable for fastening interim covers, affixing protective layers, or keeping materials secure throughout construction or renovation endeavors. Nevertheless, for extended or demanding applications, it is advisable to opt for tapes explicitly engineered for construction, as they exhibit superior resistance against weather, UV rays, and possess enhanced adhesive properties.

- Q: Can packaging tape be used for sealing packages with perishable food items?

- No, packaging tape is not suitable for sealing packages with perishable food items as it does not provide an airtight seal or protect against moisture, which can lead to spoilage and potential health risks. It is recommended to use specialized food-grade packaging materials designed for perishable items to ensure their freshness and safety.

- Q: Is packaging tape resistant to chemicals or solvents?

- Yes, packaging tape is typically resistant to chemicals and solvents.

- Q: How does packaging tape differ from masking tape?

- Packaging tape differs from masking tape primarily in terms of their intended uses and adhesive properties. Packaging tape is specifically designed for sealing boxes and packages, providing a strong and durable bond that can withstand shipping and handling. It is usually made of a strong material like polypropylene and has a strong adhesive that sticks well to various surfaces, including cardboard and plastic. On the other hand, masking tape is designed for temporary applications like painting and crafting. It has a less aggressive adhesive that allows for easy removal without leaving residue or damaging surfaces. Masking tape is typically made of paper and is not as strong as packaging tape, making it unsuitable for heavy-duty tasks like sealing boxes for shipping.

- Q: Is packaging tape resistant to chemicals or solvents?

- Yes, packaging tape is typically resistant to chemicals and solvents.

- Q: Can packaging tape be used for sealing packages with breakable items like ceramics?

- Yes, packaging tape can be used for sealing packages with breakable items like ceramics. However, it is important to ensure that the tape is applied properly to provide adequate support and protection for the fragile items. In addition to using packaging tape, it is recommended to use additional protective materials such as bubble wrap or foam padding to cushion the ceramics and minimize the risk of damage during transit.

- Q: Is packaging tape safe to use on plastic shower curtains?

- Yes, packaging tape is safe to use on plastic shower curtains. It provides a secure and reliable way to attach or mend the curtains without causing any damage.

Send your message to us

The Best 3 Packaging Tape - Green PE Stretch Film 50Micron Self Adhesive

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords