The A537CL2 container steel plate production

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

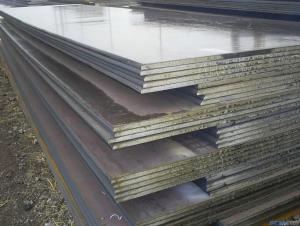

A537CL2 plate A537CL2 vessel plate

The A537Cl2 container plate is a large class of steel in

Container board with the composition and properties of special mainly be used forpressure vessel use, in use, temperature, corrosion of the different, container board material should be used, are not the same.

Heat treatment: hot rolling, controlled rolling, normalizing, normalizing + tempering,quenching tempering + (quenching and tempering)

Such as: Q345R, 16MnDR, 14Cr1MoR, 15CrMoR, 09MnNiDR, 12Cr2Mo1R, Q345R(HIC), 07MnCrMoVR, 13CrMo44,13MnNiMo54

Above is China brands, foreign brands are also many.

Such as: SA516Gr60, SA516Gr65, SA516Gr70, P355GH, P265GH and so on.

The main content of the new and old standards for control of boiler and pressure vessel steel plate

Container board Q345R delivery status description

Common delivery state are the following:

Quenching is heated to the temperature of phase transformation point: after theabove process, rapid cooling. To improve the hardness of the material, but decreases the toughness.

Normalizing: heating to above the phase transition temperature, normal cooling(air).

Annealing is heated to a temperature above the transformation point: after slow cooling. To eliminate the quenching effect, eliminate stress, uniform composition.

Tempering: after quenching, and then heated to a temperature (below thequenching temperature), insulation, and then cooling. Uniform in composition,slightly lower hardness, greatly improve the toughness.

In general: the first annealing, normalizing heat treatment to eliminate the effect ofthe original. And then quenching, tempering.

- Q: How are steel sheets protected during welding?

- Shielding plays a crucial role in safeguarding steel sheets during welding. Its purpose is to shield the sheets from oxygen and other atmospheric contaminants that can lead to oxidation and impurities in the weld. Multiple methods are utilized to shield the steel sheets during welding. One commonly employed approach involves using a shielding gas, such as argon or carbon dioxide, which is directed towards the welding area to establish a protective atmosphere. This gas displaces the surrounding oxygen, effectively preventing it from reacting with the heated metal and causing oxidation. In addition to the use of shielding gas, another widely used method involves employing flux. Prior to welding, a substance known as flux is applied to the joint area of the steel sheets. Acting as a protective barrier, the flux creates a molten slag that covers the weld and provides shielding from the atmosphere. Flux can take the form of a powder, paste, or even a continuous wire feed during welding. Furthermore, certain welding techniques, like submerged arc welding, combine the use of both shielding gas and flux to offer optimal protection for the steel sheets. This technique involves the continuous feeding of granular flux along with the welding wire. As the flux melts, it forms a protective layer over the weld, while the shielding gas effectively prevents any atmospheric contamination. Overall, the safeguarding of steel sheets during welding is crucial for ensuring the weld's quality and integrity. Shielding methods, such as the use of shielding gas and flux, establish a protective environment that prevents the formation of oxidation, impurities, and other defects in the weld. Consequently, this results in a robust and long-lasting joint between the steel sheets.

- Q: Can steel sheets be used for storage cabinets or lockers?

- Yes, steel sheets can be used for storage cabinets or lockers. Steel is a durable and strong material that is commonly used in the construction of cabinets and lockers due to its resistance to corrosion, fire, and impact. Additionally, steel provides security and longevity, making it an ideal choice for storage solutions.

- Q: Can steel sheets be used for kitchen backsplashes?

- Kitchen backsplashes can indeed utilize steel sheets. Steel is a highly versatile and enduring material that can withstand the demands of a kitchen setting. It possesses resistance against heat, moisture, and stains, rendering it an ideal selection for a kitchen backsplash. Moreover, steel backsplashes are effortless to clean and maintain, as they can be easily wiped down using a damp cloth or gentle cleaning solution. Steel sheets also contribute to a sleek and contemporary appearance, lending a touch of elegance to any kitchen design. However, it is important to mention that steel is susceptible to scratching. Hence, it is advisable to opt for a stainless steel variation, which offers enhanced resistance against scratches. All in all, steel sheets present a practical and stylish alternative for kitchen backsplashes.

- Q: How do steel sheets perform in high-temperature environments?

- Steel sheets perform well in high-temperature environments due to their high melting point and excellent heat resistance. They retain their structural integrity, maintain their mechanical properties, and do not deform or melt easily under extreme heat. Additionally, steel sheets have good thermal conductivity, allowing for efficient heat transfer and dissipation. Overall, steel sheets are a reliable and durable choice for applications requiring high-temperature resistance.

- Q: Can steel sheets be used for shipping containers?

- Yes, steel sheets can be used for shipping containers.

- Q: What is the typical yield strength of stainless steel sheets?

- The typical yield strength of stainless steel sheets can vary depending on the grade and thickness of the material. However, on average, stainless steel sheets have a yield strength ranging from 30,000 to 80,000 pounds per square inch (psi). It is important to note that different grades of stainless steel, such as 304, 316, or 430, will have different yield strengths. Additionally, the thickness of the sheet can also affect the yield strength, with thinner sheets generally having lower yield strengths compared to thicker sheets. Therefore, it is recommended to consult the specific grade and thickness specifications provided by the manufacturer or supplier to determine the exact yield strength of a particular stainless steel sheet.

- Q: How do you calculate the yield strength of a steel sheet?

- To calculate the yield strength of a steel sheet, you need to conduct a test called a tensile test. This test involves stretching a sample of the steel sheet until it reaches its breaking point. During the test, you measure the stress and strain applied to the sample. The yield strength is the point at which the material begins to deform plastically, meaning it does not return to its original shape after the stress is removed. It is an important mechanical property as it indicates the maximum amount of stress a material can withstand without permanent deformation. During the tensile test, you measure the stress applied to the steel sheet as you increase the strain on the sample. Stress is calculated by dividing the force applied to the sample by its original cross-sectional area. Strain is determined by dividing the change in length of the sample by its original length. The yield strength is defined as the stress at which a specific amount of permanent deformation occurs, typically 0.2% strain or 0.2% offset. This means that the yield strength is the stress required to cause a 0.2% change in length of the sample. Once you have obtained the stress-strain data from the tensile test, you can plot a stress-strain curve. The yield strength is then determined by finding the point on the curve where the stress corresponding to the specified amount of strain is reached. In summary, to calculate the yield strength of a steel sheet, you need to perform a tensile test and measure the stress and strain applied to the sample. From the stress-strain curve, you can determine the point at which a specific amount of permanent deformation occurs, which is the yield strength of the steel sheet.

- Q: Are steel sheets suitable for food-grade applications?

- Yes, steel sheets are suitable for food-grade applications. Stainless steel sheets, in particular, are commonly used in the food industry due to their excellent corrosion resistance, durability, and ease of cleaning. They meet the necessary hygiene standards and are non-reactive with food, making them a suitable choice for food processing, storage, and transportation.

- Q: Can steel sheets withstand extreme weather conditions?

- Yes, steel sheets are designed to withstand extreme weather conditions. Steel is known for its strength and durability, making it an ideal material for withstanding harsh weather elements such as high winds, heavy rain, snow, and extreme temperatures. Steel sheets are often used in construction, roofing, and outdoor applications where they are exposed to various weather conditions. Additionally, steel sheets can be coated with protective layers such as galvanized or painted finishes, which further enhance their resistance to corrosion and weathering. Overall, steel sheets are highly reliable and can endure extreme weather conditions with minimal damage or deterioration.

- Q: Can steel sheets be used in aerospace applications?

- Yes, steel sheets can be used in aerospace applications. However, they are mostly utilized in certain areas such as structural components and landing gear due to their high strength and durability.

Send your message to us

The A537CL2 container steel plate production

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords