Tensar Biaxial Bx Geogrids for High Tensile Strength Fiberglass in Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

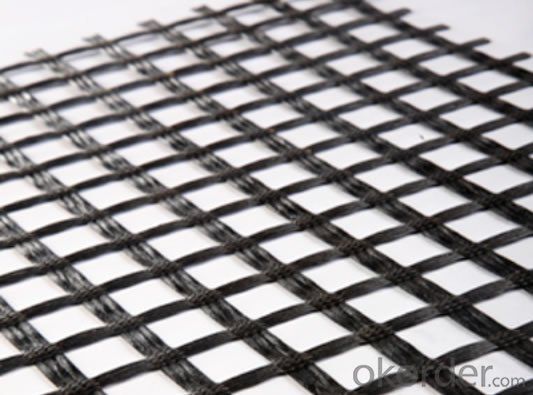

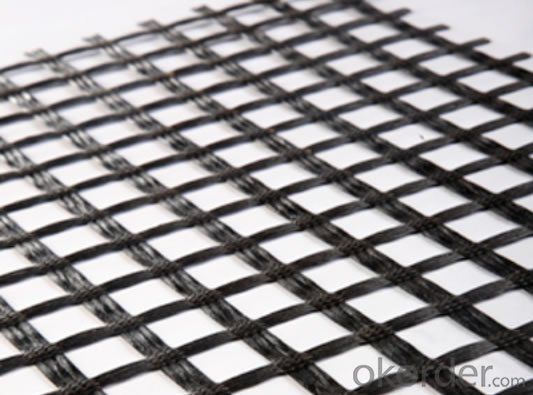

Geogrid is widely used in civil construction over the whole world. It is manufactured on the basis of high-impact polyethylene and polypropylene. Geogrids are used as reinforcement materials on mellow soils for railway and car roads, parking places, landing grounds and for the reinforcement of bridge piers, slopes and earth banks, for erosion protection of slopes.

Main application objects of the materials:

Reinforcement of highways slopes and higher steepness slopes fixation;

Bed fixation of the various types of road surfacing;

Reinforcement of littoral zone of water reservoirs and greek beds;

Fixation of the railroad cone slopes;

Support wall construction.

“Technostroytex” LLC geogrids are a honeycomb of polyethylene bands of 1.7 mm thickness (standard), bound by ultrasonic welding joints chequerwise.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geogrids be used in temporary soil stabilization applications?

- Yes, geogrids can certainly be used in temporary soil stabilization applications. Geogrids are commonly employed in various civil engineering projects to reinforce and stabilize soil. They provide temporary support and enhance the strength of the soil, preventing erosion and maintaining stability during construction or other temporary applications.

- Q: Peel force mainly in the size of raw materials

- Depends on the strength of the welding point

- Q: What are the factors that affect the long-term creep behavior of geogrids?

- The factors that affect the long-term creep behavior of geogrids include the type and quality of material used in the geogrid, the load applied on the geogrid, the duration and frequency of the load, the temperature and environmental conditions, and the installation and construction techniques employed.

- Q: Unidirectional tensile plastic geogrid manufacturers which good

- (1) the plastic geogrid plastic geogrid is a kind of polymer material with square or rectangular shape which is formed by stretching, and it can be used as one kind of unidirectional stretching and biaxial stretching according to the different direction of stretching in the manufacturing process. The utility model is punched on the extruded polymer plate (raw material is polypropylene or high-density polyethylene), and then directionally stretched under the heating condition

- Q: Are geogrids suitable for use in reinforced retaining walls?

- Yes, geogrids are suitable for use in reinforced retaining walls. Geogrids are designed to provide stability and reinforcement to the soils behind retaining walls, helping to distribute the loads evenly. They enhance the overall strength and integrity of the wall, preventing soil erosion and reducing the risk of wall failure. Geogrids are commonly used in various types of retaining walls, such as gravity walls, cantilever walls, and reinforced soil walls, making them a reliable and effective solution for reinforcement.

- Q: How do geogrids improve the performance of geosynthetic-reinforced slopes in liquefaction-prone areas?

- Geogrids improve the performance of geosynthetic-reinforced slopes in liquefaction-prone areas by providing additional stability and reinforcement to the soil. They function by distributing and transferring the load across a wider area, reducing the potential for soil liquefaction. Additionally, geogrids increase the shear strength of the soil, preventing slope failure and enhancing the overall stability of the structure.

- Q: Can geogrids be used in reinforcement of mechanically stabilized earth walls for bridge abutments?

- Yes, geogrids can be used in the reinforcement of mechanically stabilized earth walls for bridge abutments. Geogrids are commonly used to enhance the stability and load-bearing capacity of soil structures, such as retaining walls and bridge abutments. By providing tensile strength and distributing loads, geogrids help prevent soil erosion and maintain the integrity of the structure, making them an effective solution for reinforcing mechanically stabilized earth walls in bridge abutments.

- Q: What criteria should be used in the construction of Geogrid

- 1, the construction site: requirements compaction flat, horizontal, removal of the protrusion. 2, in the formation of compaction: Geogrid laying site, installation of the grid the main stress direction (longitudinal) should be perpendicular to the axis of the embankment, laying should be smooth, no wrinkles, as far as possible tension. With the plug pin and the earth pressure is fixed, the laying of the grille main stress direction is best long without joint connection between the amplitude and the amplitude of the manual banding lap, lap width not less than 10cm. If the grid is set above two layers, the seam should be staggered. After laying a large area, the overall adjustment of its flatness. When the cover of a layer of soil, not rolling before, should be used manually or machine tensioning grid, the strength should be uniform, so that the grid in the soil for the tension state. 3, the choice of packing: packing should be selected according to the design requirements. Practice has proved that, in addition to frozen soil, swamp soil, domestic waste, chalk, diatomite can be used as filler. However, the mechanical properties of gravelly soil and sandy soil are stable, and the water content is very small. Packing size should not be greater than 15cm, and pay attention to control the packing gradation, to ensure the compaction weight. 4, the packing of the paving and compaction: when the laying of the grid positioning, should be filled in a timely manner, the exposure time shall not exceed 48 hours, can also take the side of the laying of the backfill flow shop. First spread the filler at both ends, the grid will be fixed, and then to the central propulsion. Rolling sequence is the first two sides after the middle. When the roller compaction can not directly contact with the reinforced material, the non compacted reinforcement generally do not allow the vehicle to travel on the above, so as to avoid the dislocation. The degree of compaction is 20-30cm. Pressure...

- Q: Road overhaul of the original concrete pavement after washing asphalt paving, crack resistance is to use geotextile or geogrid

- Depends on the specific circumstances, the general use of grid

- Q: What are the advantages of using geogrids in ground improvement for load transfer platforms?

- Geogrids offer several advantages in ground improvement for load transfer platforms. Firstly, they enhance soil stability by reinforcing the ground, thereby increasing its load-bearing capacity. This allows for the construction of larger and more robust load transfer platforms, capable of supporting heavy loads. Additionally, geogrids help to distribute the load more evenly across the platform, reducing the risk of localized failures or settlements. Moreover, these geosynthetic materials are durable and resistant to degradation, ensuring the longevity and effectiveness of the ground improvement solution. Overall, geogrids provide a cost-effective and efficient method for strengthening and stabilizing the soil, resulting in improved performance and safety of load transfer platforms.

Send your message to us

Tensar Biaxial Bx Geogrids for High Tensile Strength Fiberglass in Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords