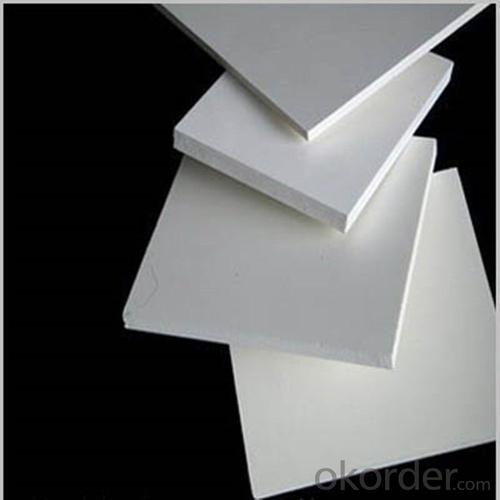

Tela Geotextil Precio White PVC Foam Board / PVC Crust Board / Rigid PVC Foam Board for Bathroom

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Product Description:

PVC Foam Sheet, a kind of high-tech product, is one product of Kingstar Plastic Sheet series. Through special machinery and technology processing, the main material PVC resin can be foamed and extruded into a special sheet with many advantages, such as shinny or matt surface, waterproof, flame-resistant, UV stable, sound and heat insulation, anti-chemical corrosion, etc.

2.Application:

1) Advertising Signs, billboards, displays, exhibition stands |

2) Screen printing, laser engraving |

3) Thermoformed parts |

4) Architecture, indoor and outdoor decoration |

5) Furniture, kitchen & bathroom cabinet |

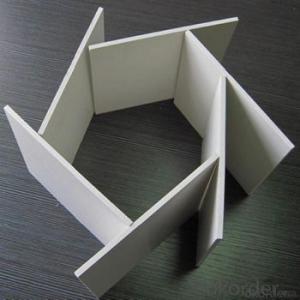

6) Walls & partitions, wall cladding |

7) Ceiling boards |

8) Poolside furniture, swimming pool floor planking |

9) Chemical industry and laboratory equipment |

10) Apparatus, container & machine construction |

11) Interior scaleboard for boat & ship, vehicle, train |

3.Feature:

1) UVprotected, Antichemical corrosion

2) Fire retardant and it can automatically extinguish by itself

3) Sound insulation, sound absorption, heat insulation and heat preservation

4) Moistureresistant, mildew proof, water repellent and shock proof

5) Nondeformation, agingresistant, color fastness for a very long time through particular formula

6) Light weight, easy and convenient for storage, transportation and using

7) It has a smooth and hard surface and is suitable for painting

4.Specifications:

1 | Product | PVC Foam sheet |

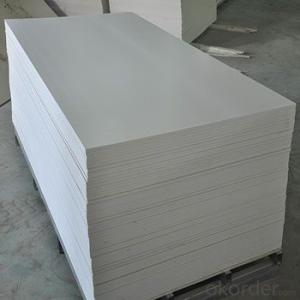

2 | Standard size | 1220mm × 2440mm; 1560mm × 3050mm; 2050mm × 3050mm ; or as your request . |

3 | Thickness | 1-33mm |

4 | Density | 0.43mm-0.9mm |

5 | Color | White, Black |

6 | Executive standard | QB/T 2463.1-1999 |

7 | Certificate | QC, SGS, PONY |

8 | Weldable | Yes |

10 | Packing | Carton box or wooden pallet packing |

11 | production capability | 100000 pcs per month |

12 | Life Span | >50 years |

13 | Flame retardance | self-extinguishing less than 5 seconds |

5.FAQ

Q: If the products have some quality problem ,how will you deal with it?

A: If the quality problem caused by us, we will provide a replacement service,and we must keep in mind. Take measures to control quality strictly,we adhere to the principle: “ quality first”.

Q: Could you provide samples?

A: Yes, We provide free samples for customers, but customer shall bear the freight charges or negotiate about this.

Q: Is free design assistance available for clients?

A: If you have problems in designing or beautifying the customized product,

we will offer you the best design assistance.

Q: What factors affect the price?

A: Style, material, dimension, quantity, logo etc.AS for your inquiry, try to give us all these information to get exact quotation.

6.Product details

- Q: What are the regulations for geotextiles in construction projects?

- The regulations for geotextiles in construction projects vary depending on the country and region. However, in general, geotextiles must meet certain standards and specifications to ensure their effectiveness and safety. These regulations typically include requirements for strength, durability, permeability, and compatibility with the specific construction application. Additionally, geotextiles may need to comply with environmental regulations, such as restrictions on harmful substances or disposal methods. It is essential to consult local building codes, industry standards, and relevant authorities to determine the specific regulations applicable to geotextiles in a construction project.

- Q: What are the key differences between woven and nonwoven geotextiles?

- The key differences between woven and nonwoven geotextiles lie in their manufacturing processes and physical characteristics. Woven geotextiles are made by interlacing yarns or fibers together to create a stable and strong fabric. On the other hand, nonwoven geotextiles are produced by bonding or felting fibers together without any weaving process. In terms of physical characteristics, woven geotextiles generally have higher tensile strength and puncture resistance due to their interlaced structure. They also offer better filtration properties as the open spaces between the woven yarns allow for effective water flow. Nonwoven geotextiles, however, have a higher permittivity, meaning they have a greater ability to allow water to pass through. Another notable difference is their durability. Woven geotextiles tend to be more resistant to UV degradation and offer better long-term performance, making them suitable for applications that require high strength and stability over time. Nonwoven geotextiles, although less durable, are often used for short-term projects or where filtration and separation are the main requirements. Overall, the choice between woven and nonwoven geotextiles depends on the specific application and desired properties. Woven geotextiles are typically favored for their strength and longevity, while nonwoven geotextiles are preferred for their filtration capabilities and cost-effectiveness in certain applications.

- Q: Can geotextiles be used in foundations and retaining walls?

- Yes, geotextiles can be used in foundations and retaining walls. Geotextiles are often used as a separation and filtration layer between the soil and the foundation or retaining wall materials. They can enhance the stability and durability of these structures by preventing soil erosion, improving drainage, and reducing the risk of soil contamination.

- Q: Basically I'm thinking of doing a thesis defense on this topic and I want to know if it is any good.

- Any bio-degradable material is not a better substitute for a geotextile material in long run Materials from polymer family may suit better, like Polyamide Polypropylene Polyethylene My answer refers to about having the ability to separate, filter, reinforce, protect, or drain If your purpose of using geotextile material regarding Beach Erosion, Riverbank Erosion, then coconut fibers is a better option

- Q: Geotextile pp-65-4-600 what it means

- PP plastic raw materials, chemical name: polypropylene, that is, polypropylene geotextile, a square meter of 600 grams of weight. Henkel Building Materials

- Q: Reservoir dam waterproof geotextile cloth two bags of a large package should be how much money

- Do not understand, to answer what is the problem with ah, Google then you deleted, Google know the system do not know how ah

- Q: Filter geotextile performance ~ main function ~

- Filter geotextile performance ~ main function ~

- Q: Can geotextiles be used in green or sustainable building practices?

- Yes, geotextiles can be used in green or sustainable building practices. Geotextiles are often utilized as a sustainable alternative to traditional construction materials. They can be employed for erosion control, soil stabilization, and drainage purposes. Geotextiles help reduce the use of non-renewable resources, minimize soil erosion, and improve water conservation. Additionally, their recyclable and biodegradable options make them an eco-friendly choice in green building practices.

- Q: What are the specifications for geotextiles in wastewater treatment projects?

- The specifications for geotextiles in wastewater treatment projects typically involve factors such as the material type, weight, thickness, permeability, and strength. These geotextiles are commonly required to have high tensile strength, puncture resistance, and durability to withstand the harsh conditions of wastewater treatment facilities. Additionally, they should have a specific permeability to allow for proper filtration and drainage of water while preventing the passage of fine particles.

- Q: What are the considerations for geotextile selection in coastal engineering projects?

- When selecting geotextiles for coastal engineering projects, several factors should be considered. These include the intended application, site conditions, longevity requirements, and environmental considerations. The geotextile's strength, permeability, and durability must align with the project's specific needs to effectively control erosion, stabilize sediment, or protect against wave action. Additionally, factors such as UV resistance, resistance to biological degradation, and compatibility with other materials used in the project should be evaluated to ensure long-term success and minimize negative impacts on the coastal ecosystem.

Send your message to us

Tela Geotextil Precio White PVC Foam Board / PVC Crust Board / Rigid PVC Foam Board for Bathroom

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords