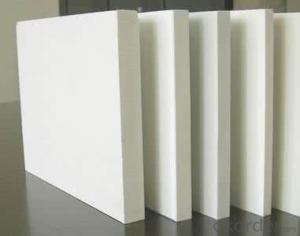

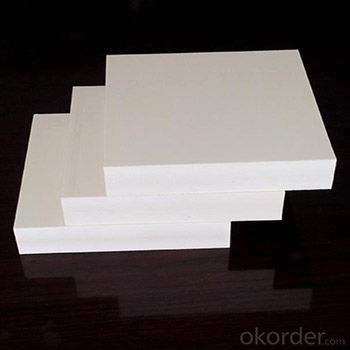

White PVC Foam Board, High Quality PVC Foam Board, Solid PVC Board for Furniture

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

C Foam Board/Sheet description:

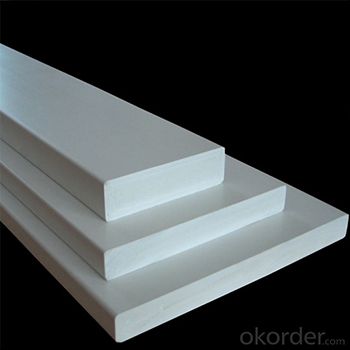

| 1 | Product | PVC Foam board/sheet/panel |

| 2 | Standard size | 1220mm × 2440mm; 1560mm × 3050mm; 2050mm × 3050mm and so on |

| 3 | Thickness | 1~33mm |

| 4 | Density | 0.45~0.9g/cm3 |

| 5 | Brand | Dio (OEM) |

| 6 | Color | White, Black, Red, Green, Pink, Grey, Blue, Yellow, etc |

| 7 | Executive standard | QB/T 2463.1-1999 |

| 8 | Certificate | ISO9001 |

| 9 | Weldable | Yes |

| 10 | Foam Process | Celuka |

| 11 | Packing | Carton box or wooden pallet packing |

| 12 | production capability | 10000 pcs per month |

| 13 | Life Span | >50 years |

| 14 | Flame retardance | self-extinguishing less than 5 seconds |

Intruduction:

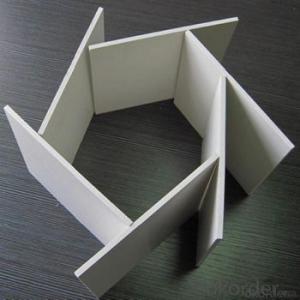

PVC foam board is a new type of environmental protective materials which instead of woods and steels. Comparing to woods ,it has many advantages, light-weight, flexible, anti-flame, alkali acid resistance, moisture proof, good heat preservation, sound insulation, shock absorption and so on. The board can be filmed or printed colorfully. It owns many ways of processing such as nailing, sawing, planning, cementing, jointing, etc

Applications:

1. Building outdoor wall board, indoor decoration board, partition board in office and house.

2. Screen printing, flat solvent printing, engraving, billboard and exhibition display.

3. Chemical anti corrosion project, special cold project, environmental protection.

4. Sanitary wares, kitchen cabinet, washroom cabinet.

PS:Advice

3mm,5mm for the cabinet back panel.

8mm for the bottom panel of drawer.

12mm for the drawer frame and the internal shelf.

15mm for the cabinet body, side panel or door panel.

16mm,18mm for the sink cabinet of kitchen cabinet.

18mm for door panel.

25mm foe door panel in case of routing

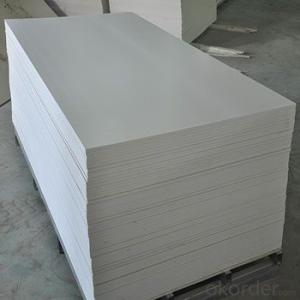

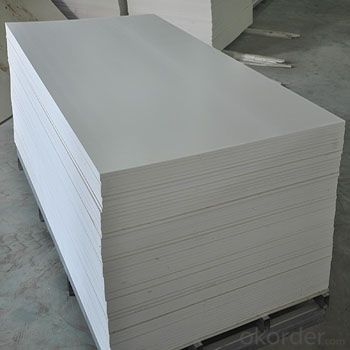

photos:

- Q: What are the common uses of plastic sheets?

- Plastic sheets have a wide range of common uses including packaging materials, construction applications, protective barriers, signage, and various DIY projects.

- Q: So I went to staples and had them laminate like 8 papers I HAVE to have laminated by tomorrow.... And I picked them up, came home, and they were literally my papers stuck between 2 plastic sheets. I can peel it easily and it is not sticking at all. Am I supposed to do something or did they mess up and forget something???? Please help!!!!

- It sounds like they messed up. My guess is that the machine was not hot enough to allow the laminate sheeting to bond. Yes, you should call them and go back. Laminating IS two plastic sheets with a paper between. However, when the machine is very hot, the plastic softens and bonds. Did you trim the papers? You should always leave a narrow edge of plastic around the edges, perhaps a quarter inch. If you trim it exactly against the paper, there is nothing on the edge to seal and bond. If they did the trimming, then check the edging. If there is a quarter edge beyond the paper and it is separating, then take it back. That could be a machine not hot enough. Take your receipt.

- Q: How to hang the net on the cement board, stick the wall tile (is the barbed wire or the plastic net) with the benzene plate glue?

- My way is to use cement workers fixed nail and then painted tiles. See wall quality whether ceramic tile adhesive?! Hope to adopt!

- Q: What are the bending capabilities of plastic sheets?

- Plastic sheets have flexible and malleable properties, allowing them to be easily bent into various shapes and angles. The bending capabilities of plastic sheets depend on their thickness, type of plastic used, and any reinforcements or additives present. Thinner sheets tend to be more flexible and easier to bend, while thicker sheets may require heat or mechanical force to achieve desired bends. However, it's important to note that excessive bending can lead to cracking or deformation in some plastics, so care should be taken to avoid exceeding their bending limits.

- Q: Are plastic sheets resistant to degradation from cleaning agents?

- Yes, plastic sheets are generally resistant to degradation from cleaning agents.

- Q: I have a FG700MS, and a strip of plastic is peeling off on the tortoise-shell pickguard, and I dunno if I'm meant to peel it off or not! LOL! It's quite new and I don't want to break it or anything, so does anyone know?

- If its just a see-through sticky plastic film that's like a giant see-through sticker covering the surface of the pick guard, it's been put there to protect the finish on the pick guard when it's in a shop or being transported. It's meant to be taken off cos it's just there to keep things clean until somebody buys it. It won't affect the guitar if you leave it on, cos I bought a Les Paul and after a few weeks I taught the pick guard paint was blistering but when i pulled at it....It was a protective plastic sticker that Gibson had put on it.

- Q: How do plastic sheets handle pressure?

- Plastic sheets can handle pressure quite well, as they are designed to be durable and flexible. The specific strength and rigidity of a plastic sheet will depend on its material composition and thickness. However, in general, plastic sheets are able to withstand moderate to high levels of pressure without deforming or breaking.

- Q: Will plastic sheeting outside window reduce the moisture condensation inside?

- well the condensation will be between the plastic sheeting and the outside window glass not on the inside of the window of your house

- Q: How much would it cost to replace a scratched plastic sheet floor in a kitchen? (approx 3x4 m2)?

- Not enough info to tell you. If you're doing the work yourself, go to a home store and price the sheet goods you want to replace it with. Read the installation directions to see what you have to do, and buy or rent the appropriate tools. Most home stores can give you plenty of advice on what you need to do. If you're not going to do the work, call some handymen and get some bids. Check their references and go with the one you like best.

- Q: Can plastic sheets be used for protective barriers?

- Yes, plastic sheets can be used for protective barriers. They are often used as a cost-effective and versatile solution to protect against physical, chemical, or biological hazards. Plastic sheets can offer transparent visibility, resistance to impact, and easy installation, making them suitable for various applications such as in healthcare settings, construction sites, or industrial environments.

Send your message to us

White PVC Foam Board, High Quality PVC Foam Board, Solid PVC Board for Furniture

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords