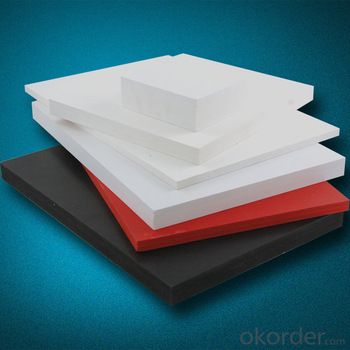

High Density PVC Foam Board For Furniture Use

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

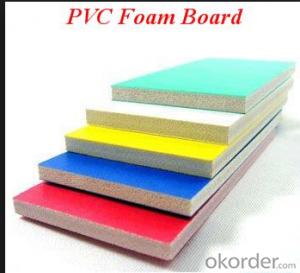

1. Product Specifications:

Specifications: 1220*2440mm, 1560*3050mm, 2050*3050mm

Thickness: 1-33mm

Density:0.43-0.9g/cm3

Color: Mainly white, Black

2 .Product usage:

1mm-5mm Suitable for advertising materials, electronic instruments, packaging

15mm-20mm Suitable for furniture

10mm-20mm Suitable for bath cabinets

5mm-20mm Exhibition board, indoor and outdoor decorative panels (different customers have different requirements)

3mm Film Suitable for car interior ceiling

PVC foam board part of the end product icon:

3 .product features and advantages

A. The characteristics of waterproof, flame retardant, acid and alkali, mothproof, lightweight, heat insulation, sound insulation and damping.

B. and the same processing of wood, and processing performance is far superior to wood

C. is an ideal substitute for wood, aluminum and composite plates.

D. skin plate surface is very smooth, high hardness, not easy to have scratches, commonly used in the production of cabinets, furniture, etc.

4 .PVC foam board market prospect:

PVC foam has many advantages, the application of a very wide range, at present in developed countries has been a very wide range of applications, and the development of more slowly in china. With the country's energy saving and environmental protection requirements of building materials and other materials and the increasing scarcity of wood resources in China, PVC foam board will usher in rapid development.

5. Product Features

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4) Easy to clean and maintain.

(5) Environmental- friendly green and lead-free.

6. FAQ:

(1)What is PVC board?

the implementation of GB/T4454-1996 quality, good chemical stability, corrosion resistance, high hardness, high strength, high strength, anti UV (aging), fireproof (self extinguishing), reliable insulation performance, smooth surface, no water, no deformation, easy processing etc.. This product is excellent heat molding material, can replace part of the corrosion resistance of stainless steel and other synthetic materials, and is widely used in petroleum, chemical industry, electroplating, water purification equipment, environmental protection equipment, and mining, medicine, electronics, communications and decoration industries.

(2)Main product specifications

Size: 1220*2440mm (about 70% of sales),

1560*3050mm (about 20% of sales),

2050*3050mm (about 10% of sales)

Main product thickness:1mm,2mm,3mm,5mm,8mm,10mm,12mm,15mm

- Q: i want to make prints on sheets like the kind used on MTG life counters. i have a website on the bottom to show what im talking about. where do i get this plastic sheets from and how do i print on them?

- There used to be a plastic material you could buy that you can run thru an inkjet printer. I found it at a computer show. Maybe a photo store would have it.

- Q: I'm looking to buy some heavy duty clear plastic sheets/strips that you typically see in the grocery store that separate the cold rooms from the colder rooms. I'm looking to get some so I can hang them from my gazebo to protect the innards from the elements. No need to comment on how ugly it will look... I'm going for function not fashion. The only thing I can find are really thin but large plastic tarps, which look like they would fly away in a light breeze.

- Not sure of trade name Heavy plastic flaps that hang from door openings to allow people machines to enter /exit without having a fixed door....right? Try Grainger's or Mc Master's online ..........might as well look under enviornmental barriers as mentioned. Best regards

- Q: What's the best glue for a plastic plate?

- Plastic board: plastic board is made of plastic, and plastic is synthetic macromolecule compound. It can change the shape of the body freely. The plastic is made of synthetic or condensation polymerization with monomer raw materials, composed of synthetic resin and filler, plasticizer, stabilizer, lubricant, pigment and other additives, it is the main component of synthetic resin.

- Q: How much would it cost to replace a scratched plastic sheet floor in a kitchen? (approx 3x4 m2)?

- Not enough info to tell you. If you're doing the work yourself, go to a home store and price the sheet goods you want to replace it with. Read the installation directions to see what you have to do, and buy or rent the appropriate tools. Most home stores can give you plenty of advice on what you need to do. If you're not going to do the work, call some handymen and get some bids. Check their references and go with the one you like best.

- Q: I want to cover the sofas with plastic sheeting. I have lazyboy type reclining sofas and was wondering if there are special covers or if there is a way of fitting them on?

- Sure they make covers for all types of sofas

- Q: Can plastic sheets be used for protective barriers in laboratories?

- Yes, plastic sheets can be used as protective barriers in laboratories. They are commonly used to create partitions, shields, or enclosures to protect against chemical splashes, contaminants, or airborne particles. Plastic sheets are often chosen for their transparency, flexibility, and resistance to corrosion, making them suitable for creating barriers that meet safety and regulatory requirements in laboratory settings.

- Q: Are plastic sheets flexible?

- Yes, plastic sheets are generally flexible as they can be easily bent or molded into different shapes.

- Q: Can plastic sheets be used for insulation against noise?

- Yes, plastic sheets can be used for insulation against noise.

- Q: It's flat, like paper, but with a layer of plastic over top of it that has grooves into it that refracts the image printed on the paper. You used to get them in cereal/crackerjack boxes, or printed on a child's plastic ruler, or sometimes even the cover of a book would have them. Depending on the angle that you hold them, you see different images. You could tip them back and forth to produce a little 5 or 6 frame animation. Or some of them even let you see some basic 3D stereoscopic images. You don't need to wear 3D glasses or anything, it's just a flat thing.What's that technology called? I'm trying to find info about them and I don't know what they're called. Is there a company that will make them for me?

- You may be talking about a Fresnel lens which is flat but provides magnification. It consists of grooves in the plastic. You can see odd optical things when you bend it or look at it at an angle. You may also be talking about a polarizing filter which physically blocks some of the light waves and allows other light waves to pass thru. The grooves are too small to see. I suppose you could have a polarized Fresnel lens.

- Q: I want to print colour diagram on thermal plastic sheet, but the ink wont dry.

- Ink needs to absorb into the surface of the media in order to dry. Thermal plastic sheet is far to smooth for ink to adhere to. You will not be able to print properly onto thermal plastic sheeting.

Send your message to us

High Density PVC Foam Board For Furniture Use

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords