Tan Packaging Tape 50 Yd Duck - Clear OPP Tape Single Side Adhesive for Binding and Holding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Material: BOPP film

Adhesive Side:Single Sided

Adhesive: Water Based Acrylic

Use: Carton Sealing and Packing,Light Duty Packing,Bounding,Holding and other office and household use

Design Printing: Offer Printing

Place of Origin: China (Mainland)

Model Number: Red opp packing tape Strong adhesive

Color: Clear, Tan, Yellowish, Brown, Yellow, White, Black, Blue, Green, Red etc.

Standard Size: 48mm x 66m, 50mm x 50m, 1.28m x 4000m, etc

TYPICAL PHYSICAL PROPERTIES:

Total Thickness (adhesives + carrier): 40 ± 2 um

Initial Tack (11mm steel ball): ³ 18#

180O Peel Adhesion (to steel): ³ 0.5 kgf /25mm

Holding Power: ³ 24 hrs

Tensile Strength: ³ 30 N/cm

Elongation: ≤180%

Applications

Economical for general carton sealing

Auto-packing machine

Gift Wrapping & Decoration

Bundling &Strapping

Meet all kinds of transportation convenientl

Advantages:

OPP tape, superb tack and adhesion to surface

Strong grip that is ensured because of an excellent adhesive backing

Quality processing equipment that guarantees consistent quality

Peak performance even under extereme conditions of pressure and temperature

Sticks on all types of surfaces (paper, plastic, wood, glass, fiber and metal)

Consistent quality

On time delivery

Effective and timely communication

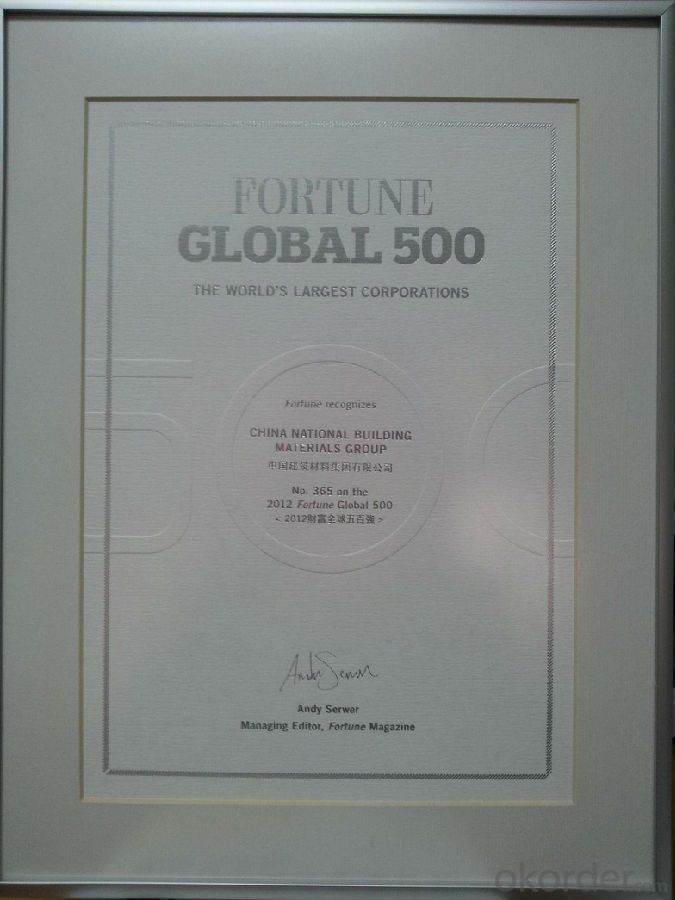

About Us

CNBM International Corp.,established in 2004,is the business entity for trade and logistics of CNBM Group,a state-owned company under the direct supervision of State-owned Assets Supervison and Administration Commission of the State Council of People's Republic of China.

We are the adhesive tape division of CNBM International Corporation.Over the past decade we have been developed into a leading manufacturer of adhesive tapes in China.We mainly supply various kinds of adhesive tapes as BOPP packing tape,cloth duct tape,double sided taps,PVC tapes,Aluminum foil tape etc.

- Q: How does packaging tape adhere to surfaces?

- Packaging tape sticks to surfaces by utilizing adhesive materials that are typically made from synthetic rubber or acrylic-based substances. These materials are specifically engineered to possess a strong bonding capability with a variety of surfaces, including cardboard, plastic, and metal. The adhesive on packaging tape functions by establishing a connection between the tape and the applied surface. When pressure is exerted on the tape, the adhesive substance spreads out and establishes contact with the surface. This contact enables the adhesive to interact with the molecules of the surface, resulting in the formation of a bond through intermolecular forces. The most commonly employed type of adhesive found on packaging tape is known as pressure-sensitive adhesive (PSA). PSA is specifically formulated to adhere to surfaces with minimal pressure. Upon the application of pressure, the adhesive substance flows and conforms to the surface, ultimately creating a robust bond. Furthermore, the adhesive on packaging tape is designed to withstand various environmental factors such as temperature, humidity, and moisture. This ensures that the tape remains firmly adhered to the surface, even in challenging conditions. In conclusion, packaging tape adheres to surfaces by utilizing adhesive materials, typically synthetic rubber or acrylic-based. These adhesives establish a bond between the tape and the surface through intermolecular forces, allowing the tape to securely stick.

- Q: How does packaging tape perform when exposed to sunlight?

- Extended exposure to sunlight can negatively affect the performance of packaging tape. Ultraviolet rays present in sunlight can cause the tape to deteriorate and lose its adhesive properties. This can result in the tape becoming brittle, yellow, and prone to peeling off. Additionally, the heat from sunlight can cause the tape to melt or deform, further impacting its effectiveness. To avoid any potential damage caused by sunlight, it is advised to store packages with packaging tape in a cool and dark location, ensuring the tape maintains its effectiveness.

- Q: What are the best practices for storing packaging tape rolls?

- The best practices for storing packaging tape rolls include keeping them in a cool and dry environment to prevent moisture damage, storing them upright to avoid deformation, ensuring they are tightly sealed to maintain adhesive quality, and keeping them away from direct sunlight and extreme temperatures to prevent tape degradation. Additionally, it is advisable to organize and label tape rolls for easy identification and access.

- Q: Can packaging tape be used for sealing bubble wrap?

- Yes, packaging tape can be used for sealing bubble wrap.

- Q: Can packaging tape be used for sealing wooden crates or pallets?

- Certainly, packaging tape is a reliable option for sealing wooden crates or pallets. Its design aims to create a strong and secure bond, making it suitable for sealing different materials, such as wood. By virtue of its adhesive properties, it adheres well to both the surface of the wooden crates or pallets and the packaging materials used to enclose them, thus ensuring a dependable seal. Moreover, packaging tape usually boasts durability and moisture resistance, safeguarding the contents of the wooden crates or pallets during transportation or storage.

- Q: Can packaging tape be used for sealing metal boxes?

- Yes, packaging tape can be used for sealing metal boxes. Packaging tape is designed to provide a secure and durable seal on various surfaces, including metal. It offers a strong adhesive that can effectively stick to metal surfaces, ensuring that the box remains sealed during transportation or storage. However, it is important to choose a packaging tape that is suitable for heavy-duty applications and can withstand the weight and pressure that may be exerted on the metal box. Additionally, it is recommended to clean the metal surface before applying the tape to ensure proper adhesion.

- Q: Is packaging tape resistant to chemicals or solvents?

- Yes, packaging tape is generally resistant to chemicals or solvents. Most packaging tapes are made from materials such as polypropylene or polyvinyl chloride (PVC) which have good chemical resistance properties. These materials are designed to withstand exposure to a wide range of chemicals and solvents commonly encountered in industrial or commercial environments. However, it is important to note that the specific resistance of packaging tape can vary depending on the brand, type, and quality of the tape. Therefore, it is always recommended to check the product specifications or consult the manufacturer for detailed information on the chemical resistance of a specific tape.

- Q: Can packaging tape be used for sealing plastic toolboxes?

- Yes, packaging tape can be used for sealing plastic toolboxes. Packaging tape is designed to securely seal boxes and packages, and it can be used on various materials, including plastic. It provides a strong and durable seal that can withstand normal handling and transportation. However, for long-term storage or heavy-duty use, it is recommended to use a stronger and more specialized tape, such as duct tape or strapping tape, as they offer better durability and adhesion.

- Q: What are the benefits of using low-noise packaging tape?

- There are several benefits of using low-noise packaging tape. Firstly, low-noise packaging tape is designed to minimize or eliminate the loud noise that traditional packaging tapes often make when they are being unwound or dispensed. This can be particularly beneficial in office or retail environments where there is a need for a quiet and peaceful atmosphere. By reducing the noise level, low-noise packaging tape helps to create a more comfortable and less disruptive work environment. Secondly, low-noise packaging tape is often made from high-quality materials that provide superior strength and adhesion. This means that it offers a reliable and secure seal on packages, reducing the risk of contents becoming damaged or lost during transit. The strong adhesive properties of low-noise packaging tape ensure that it stays in place even in challenging conditions, such as extreme temperatures or high humidity. Another benefit of low-noise packaging tape is its ease of use. It is typically designed to be easily dispensed from a tape dispenser, allowing for quick and efficient application. This saves time and effort for users, especially in high-volume packaging operations or busy shipping departments. The smooth and consistent unwinding of low-noise packaging tape further contributes to its ease of use, preventing tangles or snags that can lead to frustration and wasted tape. Additionally, low-noise packaging tape is often available in a variety of sizes, widths, and colors, allowing for customization according to specific packaging needs. This versatility ensures that it can be used for a wide range of applications, from sealing small envelopes or boxes to securing larger packages for shipping. The different color options can also help with organization and identification, making it easier to distinguish between different types of packages or to mark fragile items. In summary, the benefits of using low-noise packaging tape include reducing noise levels, providing reliable and secure seals, offering ease of use, and allowing for customization. By choosing low-noise packaging tape, businesses can improve the overall packaging experience for both employees and customers, leading to increased productivity, customer satisfaction, and the protection of valuable goods.

- Q: Is packaging tape waterproof?

- Typically, packaging tape possesses waterproof properties. Its design aims to resist moisture effectively and create a formidable seal, thereby preventing water infiltration into the package. Nonetheless, it is crucial to acknowledge that the degree of waterproofing can vary depending on the quality and type of packaging tape employed. Certain tapes may offer a more reliable seal compared to others, hence it is advisable to opt for a tape explicitly crafted for packaging and sealing applications.

Send your message to us

Tan Packaging Tape 50 Yd Duck - Clear OPP Tape Single Side Adhesive for Binding and Holding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords