Surface Finish Cold Rolled Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

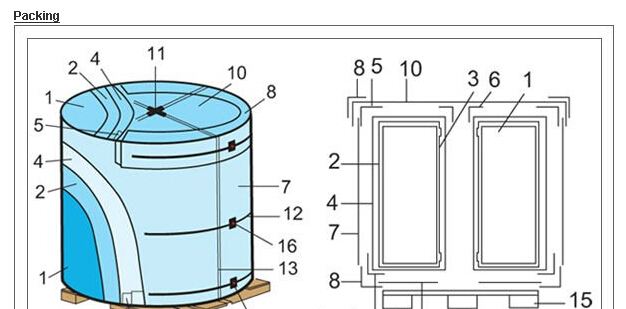

1. Thickness: 0.4-2.0mm

2. Width: 900-1250mm

3. Inner Diameter: 508&610mm

4. Weight of Steel Coil: 3-15MT

5. Heat Treatment: Annealed + Smoothed

6. Margin Status: EC & EM

7. Surface Quality: FC & FD

8. Surface Treatment: Oiling

9. Surface Status: Bright

Chemical Components

Grade | Chemical Components | ||||

C | Mn | P | S | Alt | |

DC01 | ≤0.10 | ≤0.50 | ≤0.035 | ≤0.025 | ≥0.020 |

DC03 | ≤0.08 | ≤0.45 | ≤0.030 | ≤0.025 | ≥0.020 |

DC04 | ≤0.08 | ≤0.40 | ≤0.025 | ≤0.020 | ≥0.020 |

Mechanical Properties

1. Yield Strength: ≤320MPa

2. Tensile Strength: ≤370MPa

3. Elongation (L=50mm, b=25mm) When:

(1) Nominal Thickness<0.25mm: 30%

(2) Nominal Thickness 0.25mm-<0.40: 32%

(3) Nominal Thickness 0.40-<0.60mm: 34%

(4) Nominal Thickness 0.60-<1.0mm: 36%

(5) Nominal Thickness 1.0-<1.6mm: 37%

(6) Nominal Thickness >1.6mm: 38%

- Q: What are the advantages of using steel in high-rise buildings?

- There are several advantages of using steel in high-rise buildings. Firstly, steel is a strong and durable material that can withstand high wind loads and seismic forces, making it suitable for tall structures. Secondly, steel has a high strength-to-weight ratio, allowing for lighter building components and reducing the overall weight of the structure. This, in turn, reduces foundation requirements and construction costs. Additionally, steel is a versatile material that can be easily fabricated and assembled, allowing for efficient construction and faster project completion. Finally, steel is a sustainable option as it can be recycled and reused, minimizing environmental impact and promoting sustainability in the construction industry.

- Q: How does the thickness of steel affect its strength?

- The thickness of steel directly affects its strength. Generally, thicker steel tends to be stronger and more resistant to deformation or failure under load. This is because thicker steel has a greater cross-sectional area, which allows it to distribute and withstand forces more effectively. Thicker steel also provides a larger volume for the material to absorb energy before reaching its breaking point. However, it is important to note that there is a trade-off between thickness and other factors such as weight and cost, so the optimal thickness depends on the specific application and requirements.

- Q: What are the different types of steel fencing and their applications?

- There are several types of steel fencing available, each with its own unique applications. Some common types include chain link fencing, ornamental steel fencing, and welded wire fencing. Chain link fencing is widely used for commercial and residential purposes due to its affordability and durability. Ornamental steel fencing, on the other hand, is more decorative and often used for residential properties or to enhance the aesthetics of public spaces. Lastly, welded wire fencing is commonly used for agricultural or livestock purposes, as it provides a secure enclosure while still allowing visibility. Ultimately, the choice of steel fencing depends on the specific requirements and desired appearance of the application.

- Q: What are the advantages of using steel products in the automotive industry?

- There are several advantages of using steel products in the automotive industry. Firstly, steel is known for its strength and durability, making it an ideal material for constructing various automobile components. This ensures the safety of passengers and enhances the overall structural integrity of vehicles. Additionally, steel is highly resistant to corrosion, making it suitable for withstanding harsh environmental conditions and extending the lifespan of automotive parts. Moreover, steel can be easily formed and shaped, allowing manufacturers to design and produce complex structures efficiently. Lastly, steel is relatively affordable compared to other materials, making it a cost-effective choice for automotive manufacturers.

- Q: What are the different types of steel gratings and their applications?

- There are several types of steel gratings, including welded steel gratings, pressure-locked steel gratings, and riveted steel gratings. Welded steel gratings are commonly used in industrial platforms, walkways, and stair treads due to their high strength and durability. Pressure-locked steel gratings are suitable for architectural applications such as building facades and sunshades, as they offer an aesthetically pleasing design. Riveted steel gratings, on the other hand, are commonly used in heavy-duty applications such as bridge decks and airport runways due to their exceptional load-bearing capacity.

- Q: How is steel used in the production of agricultural machinery?

- Steel is commonly used in the production of agricultural machinery due to its strength, durability, and versatility. It is used to construct various components such as frames, chassis, and implements, ensuring the equipment can withstand the demands of farming operations. Steel's robust nature allows agricultural machinery to handle heavy workloads, endure harsh environments, and provide long-lasting performance, making it an ideal material for the industry.

- Q: How do steel products contribute to the retail and commercial sector?

- Steel products contribute to the retail and commercial sector by providing durable and versatile materials for construction, manufacturing, and display purposes. From steel shelving units and storage racks to shop fittings and display stands, these products offer strength, stability, and longevity, ensuring the efficient organization and presentation of merchandise in retail stores. Additionally, steel is commonly used in commercial buildings, such as malls and office complexes, for its structural integrity, fire resistance, and aesthetic appeal. Overall, steel products are essential in enhancing the functionality, safety, and visual appeal of retail and commercial spaces.

- Q: What are the different types of steel forgings and their uses?

- There are several types of steel forgings, each with its own unique properties and uses. Some common types include open-die forgings, closed-die forgings, and seamless rolled ring forgings. Open-die forgings are used for large and complex parts, such as turbine shafts and pressure vessels. Closed-die forgings are ideal for smaller and intricate components like automotive parts and hand tools. Seamless rolled ring forgings are commonly used in applications requiring high strength and durability, such as gears, bearings, and flanges. Overall, steel forgings offer superior strength, reliability, and resistance to wear, making them essential in various industries including aerospace, automotive, and oil and gas.

- Q: What are the advantages of using steel in the manufacturing of playground equipment?

- There are several advantages of using steel in the manufacturing of playground equipment. Firstly, steel is a highly durable material that can withstand heavy use and harsh weather conditions, making it ideal for outdoor play areas. Secondly, steel is resistant to corrosion, which ensures the longevity of the playground equipment and reduces maintenance costs. Additionally, steel is a versatile material that can be easily molded into various shapes and designs, allowing for the creation of innovative and engaging play structures. Lastly, steel is a safe option as it has high strength-to-weight ratio, providing stability and support for children while they play.

- Q: What are the safety regulations and standards for steel product manufacturing?

- The safety regulations and standards for steel product manufacturing vary depending on the country and industry. However, common safety guidelines include proper handling and storage of raw materials, the use of personal protective equipment (PPE) by workers, implementation of proper ventilation systems to control airborne contaminants, regular equipment maintenance and inspections, adherence to machine guarding protocols, and ensuring proper training and education for employees to minimize hazards and accidents. Additionally, steel manufacturers are often required to comply with specific industry standards such as ISO 9001 for quality management and ISO 14001 for environmental management.

Send your message to us

Surface Finish Cold Rolled Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords