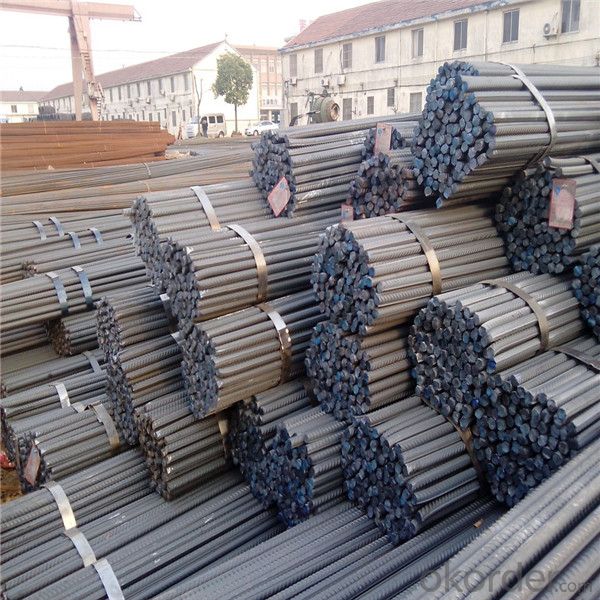

Steel rebar manufacturer supply deformed steel rebar

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 17497 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Rebar has ridges that bind it mechanically to the concrete with friction, it can still be pulled out of the concrete

under high stresses, an occurrence that often precedes a larger-scale collapse of the structure. To prevent such a

failure, rebar is either deeply embedded into adjacent structural members, or bent and hooked at the ends to lock it

around the concrete and other rebars. This first approach increases the friction locking the bar into place while the

second makes use of the high compressive strength of concrete

Rebar is common steel reinforcing bar, an important component of reinforced concrete and reinforced masonry structures.

It is usually formed from mild steel, and is given ridges for better frictional adhesion to the concrete

Product Description :

Chemical composition (%): | Steel | C | Si | Mn | P | S | Ceq | ||||

HRB335 |

0.25 |

0.80 |

1.60 |

0.045 |

0.045 | 0.52 | |||||

HRB400 | 0.54 | ||||||||||

HRB500 | 0.55 | ||||||||||

Mechanical properties | Steel | Rel/ MPa | Rm/ MPa | A/ % | Agt/ % | ||||||

≥ | |||||||||||

HRB335 | 335 | 455 | 17 |

7.5 | |||||||

HRB400 | 400 | 540 | 16 | ||||||||

HRB500 | 500 | 630 | 15 | ||||||||

Package: | Standard export packing or as customer's request | ||||||||||

Application: | Construction, building, bridge, road. ect | ||||||||||

Payment terms | 1).100% irrevocable L/C at sight. | ||||||||||

Delivery time | 15-30 days after receipt of L/C or deposit by T/T | ||||||||||

Features

1、Pure steel quality, stable chemical contents, small tolerance.

2、Constant Quality, good drawing performance.

3、High dimension accuracy degree, accuracy degree of Level C up to 80%, smooth surface, less scale, easy to be pickled.

4、Automatic bundling with 4 lines by Machine in tidy and good looks

5、Big high quality percentage, small coil percentage, and heavy coil weight for Hard Coil.

6、High sorbitizing percentage.

Packing:

In bundles, each bundle weight 3.5 tons. Load by container or by bulk verssel.

FAQ:

1.Q: What's your MOQ(minimum order quantity)?

A: One full container, mixed acceptable .

2. Q: What's your packing methods?

A: Packed in bundle or bulk ..

3. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

4. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

5. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q: How do steel rebars affect the fire resistance of a structure?

- The fire resistance of a structure can be affected both positively and negatively by steel rebars. On the positive side, steel rebars provide added strength and stability, enhancing the fire resistance. Having steel rebars in concrete structures can prevent collapse during a fire, giving occupants more time to evacuate and allowing emergency responders to control the situation. However, there are also drawbacks to steel rebars when it comes to fire resistance. Steel is a highly conductive material, meaning it transfers heat quickly. During a fire, the steel rebars can heat up and transfer the heat to the surrounding concrete, potentially weakening its structural integrity. This weakens the fire resistance of the structure. To counteract the negative effects of steel rebars on fire resistance, certain measures can be taken. One common approach is to apply fire-resistant coatings or wraps to the steel rebars. These coatings or wraps act as a barrier, slowing down the heat transfer from the steel to the concrete and enhancing fire resistance. Additionally, the size, spacing, and arrangement of steel rebars also play a role in fire resistance. Proper design and placement of rebars ensure that heat is distributed evenly, reducing the risk of localized weakening and structural failure. In conclusion, steel rebars have a significant impact on the fire resistance of a structure. While they improve overall strength and stability, they can also contribute to heat transfer and potential weakening. By implementing appropriate measures such as fire-resistant coatings and proper design, the negative effects of steel rebars on fire resistance can be minimized, ensuring the safety and integrity of the structure during a fire.

- Q: Can steel rebars be used in the construction of residential towers and skyscrapers?

- Yes, steel rebars can be used in the construction of residential towers and skyscrapers. Steel rebars are commonly used as reinforcement in concrete structures to provide strength and stability. Due to their high tensile strength and durability, steel rebars are ideal for withstanding the heavy loads and stresses experienced by tall structures. They play a crucial role in ensuring the structural integrity and safety of residential towers and skyscrapers.

- Q: How do steel rebars help in distributing load in a structure?

- Playing a crucial role in the distribution of load within a structure, steel rebars, also known as reinforcement bars, are of utmost importance. Their primary purpose lies in reinforcing concrete structures, elevating their strength and durability. Strategically positioned within the concrete, rebars effectively counteract any tensile forces that the structure may face. Although concrete possesses strength in compression, it lacks the same strength in tension. Under the application of a load, such as in a building or a bridge, tensile forces arise, causing concrete to crack and eventually fail. By incorporating steel rebars into the concrete, these tensile forces are efficiently disseminated and transferred to the rebars, preventing excessive deflection or collapse of the structure. The inclusion of steel rebars within the concrete creates a composite material, amalgamating the compressive strength of concrete with the superior tensile strength of steel. Consequently, the structure becomes capable of withstanding a wide range of loads, including dead loads (the weight of the structure itself), live loads (such as occupants or furniture), and environmental loads (such as wind or earthquakes). Moreover, rebars serve the purpose of controlling and minimizing the propagation of cracks within the concrete. When a crack forms under load, rebars act as a barrier, impeding the crack's further spread and safeguarding the structure's integrity. This hinders the development of larger cracks that could potentially lead to structural failure. Furthermore, steel rebars provide stability and reinforcement at critical points within the structure, such as corners, joints, and areas prone to high stress. By reinforcing these vulnerable areas, rebars ensure that the load is evenly distributed throughout the structure, reducing the risk of localized failures. In conclusion, steel rebars are indispensable in distributing load within a structure by absorbing tensile forces, strengthening concrete, preventing crack propagation, and reinforcing critical locations. They significantly contribute to the overall structural integrity and safety, solidifying their vital role in construction projects.

- Q: What's the difference between primary and two grade steel and three grade steel?

- There are two kinds of commonly used classification methods of thread steel: one is to shape classification, according to different space shapes and transverse rib rib for classification or type, such as the British Standard (BS4449), the thread steel is divided into type I and type ii. This classification mainly reflects the tightening performance of the threaded steel.

- Q: What is the role of steel rebars in reducing concrete shrinkage?

- The reinforcement and added strength provided by steel rebars are crucial in minimizing concrete shrinkage. When concrete cures, it goes through hydration, a process in which it loses water and shrinks. This shrinkage has the potential to cause cracking and structural instability. By incorporating steel rebars into the concrete, they serve as reinforcement and help counteract shrinkage. These rebars offer tensile strength, which means they can resist pulling or stretching forces. As the concrete shrinks, the rebars hold it together and prevent excessive cracking. Moreover, steel rebars aid in distributing the load more evenly throughout the concrete structure. This reduces stress concentration in specific areas and further reduces the likelihood of shrinkage-related cracking. Additionally, steel rebars can act as thermal conductors, promoting even heat dissipation within the concrete. This prevents temperature differences within the structure, which can lead to differential shrinkage and subsequent cracking. To summarize, steel rebars play a vital role in reducing concrete shrinkage by providing reinforcement, resisting tensile forces, distributing loads, and regulating temperature differences. Consequently, they enhance the overall durability and stability of the concrete structure, minimizing the adverse effects of shrinkage.

- Q: What are the environmental impacts of using steel rebars in construction?

- The use of steel rebars in construction has several environmental impacts, both positive and negative. One of the positive impacts is that steel is a highly durable and long-lasting material, which means that structures built with steel rebars have a longer lifespan. This reduces the need for frequent repairs or replacements, ultimately reducing the amount of waste generated over time. However, the production of steel rebars has significant negative environmental consequences. Steel is made from iron ore, which requires extensive mining operations. These mining activities can lead to deforestation, habitat destruction, and soil erosion. Additionally, the extraction and processing of iron ore require large amounts of energy, contributing to greenhouse gas emissions and air pollution. Furthermore, the manufacturing process of steel rebars involves the use of various chemicals, such as limestone and coke, which can have detrimental effects on local ecosystems and water sources if not properly managed. The release of pollutants and waste products during steel production can also contribute to water and soil pollution. Transportation of steel rebars from production facilities to construction sites also has environmental implications. Long-distance transportation can result in increased carbon emissions and energy consumption, especially if the rebars are imported from distant locations. To mitigate these environmental impacts, sustainable practices can be adopted in the production and use of steel rebars. Recycling steel is a crucial step in reducing the demand for new production and minimizing the environmental footprint. By using recycled steel, the energy consumption and greenhouse gas emissions associated with production can be significantly reduced. Additionally, implementing efficient transportation methods, such as using rail or waterways instead of trucks, can reduce the carbon footprint of steel rebars. Overall, while steel rebars offer durability and longevity in construction, their production and use have significant environmental implications. Adopting sustainable practices and focusing on recycling can help minimize the negative impacts and make their use more environmentally friendly.

- Q: How are steel rebars used in the construction of chemical processing plants?

- Steel rebars are commonly used in the construction of chemical processing plants to provide structural reinforcement and increase the overall strength and durability of the structures. These rebars, also known as reinforcing bars, are typically made of carbon steel and are used to reinforce concrete structures such as foundations, walls, columns, and beams. Chemical processing plants often involve the handling of hazardous and corrosive substances, which can put significant stress on the infrastructure. Steel rebars are crucial in ensuring the integrity of the structures and preventing potential collapse or failure. In the construction of chemical processing plants, steel rebars are usually embedded within the concrete to form a reinforced concrete structure. This combination of concrete and steel rebars creates a composite material that has enhanced tensile strength, allowing it to withstand the heavy loads, vibrations, and extreme temperature fluctuations commonly found in chemical plants. Additionally, the use of steel rebars helps prevent cracks and structural deformations caused by shrinkage, settling, or external forces. This is important in chemical processing plants where maintaining a secure and stable environment is crucial for the safety of employees and the integrity of the plant's operations. Moreover, steel rebars offer excellent resistance to corrosion, which is vital in chemical processing plants where exposure to corrosive chemicals and high humidity levels is common. By providing a protective barrier to the underlying concrete, steel rebars help prevent corrosion-induced deterioration, extending the lifespan of the structures and reducing maintenance costs. Overall, steel rebars play a critical role in the construction of chemical processing plants by ensuring the structural stability, durability, and resistance to corrosion necessary for the safe and efficient operation of these facilities.

- Q: How are steel rebars classified based on grades?

- Steel rebars are classified based on grades according to their yield strength and tensile strength. The grades range from 40 to 60, with higher numbers indicating higher strength.

- Q: Can steel rebars be used in sustainable construction practices?

- Yes, steel rebars can be used in sustainable construction practices. Steel is a highly sustainable material as it is 100% recyclable, meaning that steel rebars can be reused or recycled at the end of their lifespan. Additionally, steel has a long life span, is durable, and provides structural strength, making it an ideal choice for sustainable construction practices.

- Q: How are steel rebars bent during construction?

- Steel rebars are typically bent during construction using specialized equipment such as hydraulic benders or rebar bending machines. These machines apply force to the rebar, causing it to bend into the desired shape. The process may involve heating the rebar to make it more malleable before bending. Skilled workers follow specific bending instructions and use measurements to ensure the rebars are bent accurately according to the construction plans.

Send your message to us

Steel rebar manufacturer supply deformed steel rebar

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 17497 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords