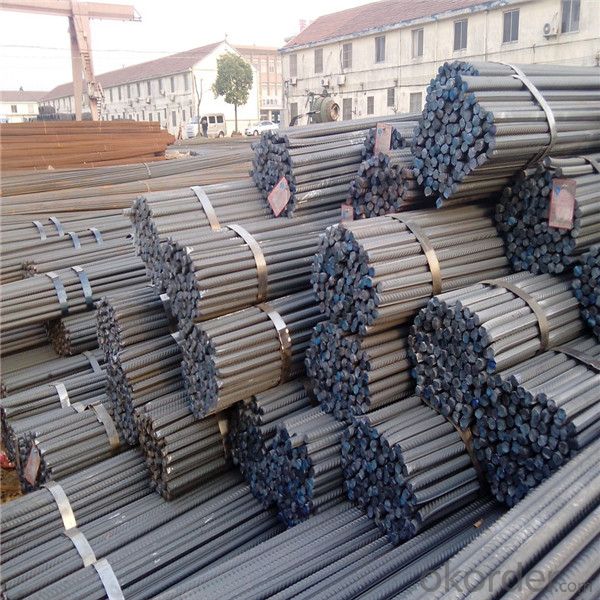

Cheap export Deformed Steel Bar for construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 19452 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

steel rebar is metal bars often used in construction for pouring concrete or supporting walls and columns.

The rebar can be smooth, though they are frequently manufactured with deformations that create greater

texture to which concrete can adhere, creating a stronger bond that helps prevent cracking of concrete.

These deformations do not create weaknesses in the rebar, and when rebar is measured to determine its

diameter, it is typically measured at the narrowest point.

To prevent workers from accidentally impaling themselves, the protruding ends of steel rebar are often bent

over or covered with special plastic "mushroom" caps

Our Advantage:

High quality steel products from 1 class mills in China

Reasonable price

Professionalism of the products

On-time delivery

Complete documents and certificates

Sincere service to meet our clients' requirements

Product Description :

Chemical composition (%): | Steel | C | Si | Mn | P | S | Ceq | ||||

HRB335 |

0.25 |

0.80 |

1.60 |

0.045 |

0.045 | 0.52 | |||||

HRB400 | 0.54 | ||||||||||

HRB500 | 0.55 | ||||||||||

Mechanical properties | Steel | Rel/ MPa | Rm/ MPa | A/ % | Agt/ % | ||||||

≥ | |||||||||||

HRB335 | 335 | 455 | 17 |

7.5 | |||||||

HRB400 | 400 | 540 | 16 | ||||||||

HRB500 | 500 | 630 | 15 | ||||||||

Package: | Standard export packing or as customer's request | ||||||||||

Application: | Construction, building, bridge, road. ect | ||||||||||

Payment terms | 1).100% irrevocable L/C at sight. | ||||||||||

Delivery time | 15-30 days after receipt of L/C or deposit by T/T | ||||||||||

Features

1、Pure steel quality, stable chemical contents, small tolerance.

2、Constant Quality, good drawing performance.

3、High dimension accuracy degree, accuracy degree of Level C up to 80%, smooth surface, less scale, easy to be pickled.

4、Automatic bundling with 4 lines by Machine in tidy and good looks

5、Big high quality percentage, small coil percentage, and heavy coil weight for Hard Coil.

6、High sorbitizing percentage.

Packing:

In bundles, each bundle weight 3.5 tons. Load by container or by bulk verssel.

Our service

(1) We cooperate with famous factories with advanced equipment and well trained workers.

(2) We can provide factory price with trading company service.

(3) We continuously work on the improvement of our processes, guaranteeing consistently high standards

of quality to keep none compensation.

(4) We guarantee 24 hours response and 48 hours solution providing service.

(5) We accept small order quantity before formal cooperation.

(6) We deliver the agreed quality at the agreed time, reacting to changes in customer wishes in a flexible way.

(7) Due to our volume and selling power, we have excellent freight rates with shipping lines.

(8) We strive to always be fair and honest in our dealings with customers.

(9) We strive to work together with customers to achieve much more than we can achieve alone.

(10) Through our passion and commitment we aim to be a market leader in all our key markets. To maintain

our position as market leader we must continue to add value in all that we do.

FAQ:

1.Q: What's your MOQ(minimum order quantity)?

A: One full container, mixed acceptable .

2. Q: What's your packing methods?

A: Packed in bundle or bulk ..

3. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

4. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

5. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q: How are steel rebars stored and handled on construction sites?

- Steel rebars, also referred to as reinforcing bars, play a vital role in construction projects that involve reinforced concrete structures. To guarantee their safety and effective utilization, these rebars are systematically and meticulously stored and managed on construction sites. Initially, steel rebars are typically delivered to construction sites bundled together and secured with wire or binding materials. Once unloaded from the delivery truck, they are carefully placed in specific areas called rebar yards or cages. These designated spaces are purposefully designed to accommodate the rebars' length, size, and weight, ensuring that they are elevated above the ground and shielded from moisture, dirt, and potential damage. Within the rebar yard, the rebars are commonly arranged horizontally and grouped based on their size, length, and grade. This arrangement enables easy identification and accessibility when required for construction purposes. Moreover, spacers or wooden blocks are often placed between the rebars to prevent direct contact, minimizing the risk of corrosion or entanglement. When it comes to handling steel rebars, construction workers must prioritize safety and adhere to specific guidelines. It is essential to wear personal protective equipment, such as gloves and safety boots, to prevent injuries and maintain a secure grip on the rebars. In certain cases, lifting equipment like cranes or forklifts may be utilized to move and transport the rebars to different areas of the construction site. During transportation, it is crucial to properly secure the rebars to prevent any shifting or falling that could result in accidents. Dragging the rebars on the ground should be avoided, as it can cause damage or deform their shape, compromising their structural integrity. It is of utmost importance to inspect steel rebars before use to ensure they meet the required specifications and are free from any defects. Rusty or damaged rebars should be either discarded or repaired, depending on the severity of the issue. In conclusion, steel rebars are stored and handled with great care and attention on construction sites. Proper storage in designated rebar yards, appropriate grouping and separation, and adherence to safety guidelines during handling are all crucial factors that contribute to the successful and efficient use of steel rebars in construction projects.

- Q: Can steel rebars be used in tunnel boring machine (TBM) construction?

- Yes, steel rebars can be used in tunnel boring machine (TBM) construction. Steel rebars are commonly used to reinforce concrete structures, including tunnels built using TBM technology. The rebars provide additional strength and stability to the concrete lining, ensuring the structural integrity of the tunnel.

- Q: How do steel rebars contribute to the ductility of reinforced concrete structures?

- Steel rebars contribute to the ductility of reinforced concrete structures in several ways. Ductility refers to a material's ability to deform under stress without fracturing. In the case of reinforced concrete structures, steel rebars provide the necessary tensile strength that concrete lacks, enabling the structure to withstand the forces of tension and compression. Firstly, steel rebars effectively resist tensile forces. Concrete is strong in compression but weak in tension. By adding steel rebars within the concrete, the structure gains the ability to withstand tensile stresses. When the concrete is subjected to tension, the rebars carry the load and prevent the concrete from cracking or failing. This enhances the overall ductility of the structure by allowing it to deform and absorb energy without catastrophic failure. Secondly, steel rebars act as reinforcement by distributing applied loads across a wider area. When a reinforced concrete structure is subjected to a load, the stress is transferred from the concrete to the rebars. The rebars distribute this stress throughout the structure, reducing localized concentrations and preventing sudden failure. This redistribution of stress promotes the ductility of the structure by enabling it to flex and absorb energy, rather than experiencing brittle failure. Moreover, steel rebars also provide anchorage and confinement to the concrete. The rebars are typically embedded in the concrete, creating a bond between the two materials. This bond enhances the overall strength and ductility of the structure by preventing the rebars from slipping or pulling out under tension. Additionally, the confinement effect of the rebars prevents the concrete from expanding or spalling under stress, increasing the overall ductility of the reinforced concrete structure. In summary, steel rebars contribute to the ductility of reinforced concrete structures by providing tensile strength, redistributing stress, and offering anchorage and confinement to the concrete. By reinforcing the weak areas of the concrete and allowing for controlled deformation, steel rebars enable the structure to absorb energy and withstand external forces without catastrophic failure.

- Q: Can steel rebars be bent or shaped during construction?

- Yes, steel rebars can be bent or shaped during construction. They are commonly used in reinforced concrete structures and can be bent to fit the required design, shape, or structure.

- Q: What is the corrosion resistance of steel rebars?

- The corrosion resistance of steel rebars is generally high due to the presence of a protective oxide layer on the surface of the steel. However, in certain environments, such as those with high levels of moisture or exposure to corrosive substances, the rebars may be susceptible to corrosion. Therefore, additional measures such as proper concrete cover, epoxy coating, or galvanization are often employed to enhance the corrosion resistance of steel rebars.

- Q: How do steel rebars contribute to the strength of concrete?

- Steel rebars contribute to the strength of concrete by providing reinforcement and increasing its tensile strength. The rebars are embedded in the concrete, forming a strong bond between the two materials. This helps to distribute the load evenly and prevent cracks or fractures from forming, making the concrete structure more resistant to bending, shearing, and other external forces.

- Q: Are there any disadvantages of using steel rebars in construction?

- Yes, there are some disadvantages of using steel rebars in construction. Firstly, steel rebars are susceptible to corrosion, especially in humid or coastal areas, which can weaken the structure over time. Secondly, steel rebars can be expensive compared to alternative materials like fiberglass or carbon fiber, increasing construction costs. Additionally, steel rebars are heavy, which can make handling and transportation challenging. Lastly, steel rebars have a high thermal conductivity, which can lead to increased heat transfer and energy loss in buildings.

- Q: What is the typical cost of steel rebars per ton?

- The typical cost of steel rebars per ton can vary depending on various factors such as the type and grade of rebar, market conditions, and location. However, as of 2021, the average price range for steel rebars is approximately $600 to $900 per ton.

- Q: Can steel rebars be bent on site?

- Yes, steel rebars can be bent on site using specialized tools and equipment such as rebar benders.

- Q: How are steel rebars transported to the construction site?

- Steel rebars are typically transported to the construction site using flatbed trucks or trailers. These vehicles are specifically designed to carry heavy loads and have the necessary infrastructure to secure and transport the rebars safely.

Send your message to us

Cheap export Deformed Steel Bar for construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 19452 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords