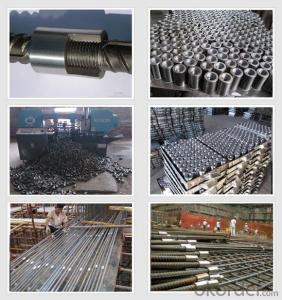

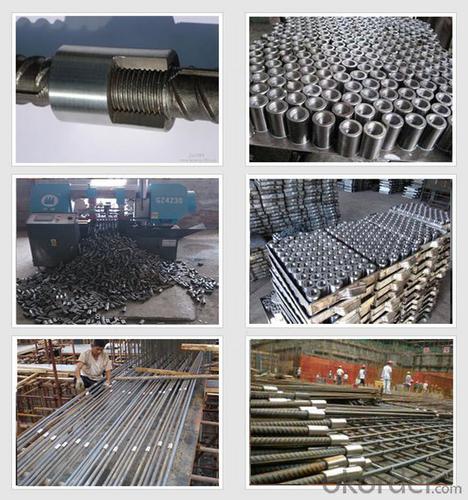

Steel Rebar Couplers Made in China with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Steel Rebar Couplers Made in China with High Quality

1.Description of Steel Rebar Couplers Made in China with High Quality:

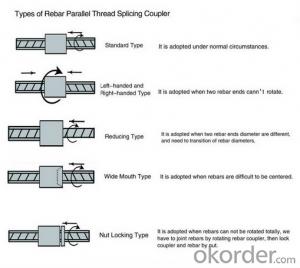

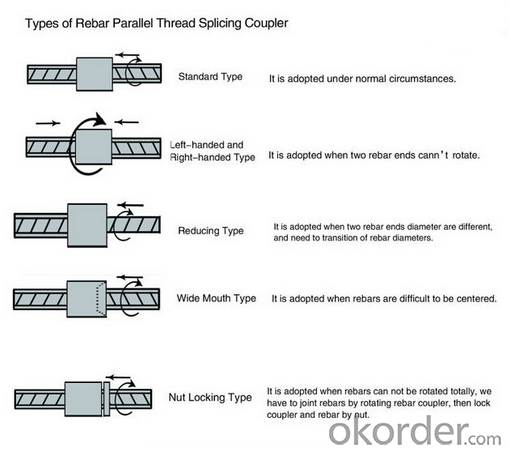

Lapped joints are not always an appropriate means of connecting rebar. The use of Steel Rebar Couplers can simplify the design and construction of reinforced concrete and reduce the amount of reinforcement required.

The threaded steel coupler system is designed as a threaded reinforcement connection with 100% load transmission. The steel coupler rebar connection system is suitable for both static and dynamic load transmission in construction joints.

The coupler is designed as a threaded reinforcement connection for formed construction joints. Reinforcement work is normally carried out on both sides of the construction joint using lap joints or one side is anchored. The bar lengths are based on the structural analysis requirements of the building component and are calculated from anchorage and lap lengths.

2.Advantages of Steel Rebar Couplers Made in China with High Quality:

The coupler system provides the opportunity to connect rebars quickly, easily and cost effectively, even when large rebar diameters are used. This makes the steel coupler rebar range a logical extension to our rebendable CNBM reinforcement continuity system for rebars over 12 mm.

3.Available sizes of Steel Rebar Couplers Made in China with High Quality:

14mm,16mm,18mm,20mm,22mmm,25mm,28mm,32mm,36mm,40mm

4.Delivery:

Delivery Term: FOB / CFR / CIF available.

Delivery Time: 15 days or less after order confirmed.

5.Why choose us?

Technical Expertise

Experienced Management

Stringent Quality Control

Exemplary Service

On-Time Delivery

Wide Product Range

Competitive Pricing

Huge branch network capable of catering worldwide

- Q: I would like a scaffold piercing, but my parents aren't going to let me have two cartilage piercings at once. So, can they be done separately, as in weeks apart?

- Technically yes but it is better to have them done at the same time so the holes are aligned properly. It is better to get them done at the same time, as the second piercing will be less painful because you are all adrenalin-ed up! Probably cheaper too.

- Q: Does anyone know the name of the song or perhaps have a link to the video if they have seen it on net for example on youtube.?

- it is umm Ain's comin down til the sun comes down

- Q: What are the requirements for the construction of the scaffold eye in the building?

- The surface of the steel pipe shall be smooth and free of cracks, scars, delamination, dislocation, hard bending, burrs, indentation and deep scratches.The outer diameter of steel pipe 48mm allowable deviation is 0.5mm; the thickness of the wall 3.5mm allowable deviation of.0.5mm; steel pipe surface cutting oblique deviation 1.7mm;

- Q: hi guys i got my scaffold piercing a couple of days ago and it keeps bleeding on and off and there was dry blood but i removed it and its bleeding more what could i do step by step to keep total care of my piercing to get rid of all these problem please help it will really be appreciated

- Dab it with tissue until it stops, Try not to play with it too much and if you need to touch it, ALWAYS wash your hands before doing so. Also do hot salt water soaks (as hot as you can stand) twice a day and it'll heal nicely in no time :)

- Q: I couldn't believe it, but yes it happened...

- yea I can believe that. There have been people who have survived jumping out of planes at ten thousand feet. One guy landed in a snow bank and I think another hit a tree and I guess it was some kind of pine and the branches slowed him down.

- Q: so yeah as it says above^should i just wait till it no longer hurts, or do you have to wait a certain amount of time...

- Industrial piercings take 9-12 months to heal completely and you never want to remove an unhealed piercing unless the jewelry is causing problems and at that point it should be done by a professional in a sterile environment. Taking the jewelry out before it is healed could cause it to close up, become infected or irritated, and can cause hypertrophic scarring (scar tissue) to form on your piercing. I took my industrial out after having it for 3 months. It was out for less than a minute and when I went to put it back in it went through the first hole easily but wouldn't go through the top hole no matter how hard I pushed. It immediately started bleeding and hurtling like crazy. Awesome. Waste of time, pain, and money. So, you might get lucky and just have it get a little irritated or prolong the healing time by changing it early. But you could also end up like me or worse, with any infected piercing. Why risk it?

- Q: What are scaffold spanners used for?

- Ratchet Podger Spanners...Aluminium Scaff Spanners Spanners are wide wrenches that are made from durable metals. Spanners are made specifically for scaffolding and are designed to fit into the tool belt nicely. Spanners are very useful for a number of jobs and are often used along with other scaffold tools on a safety lanyard to prevent dropping the tool to the street below. Spanners work the same as traditional wrenches but like many scaffolding tools are made with a hole in the end of the wrench for the safety strap to be inserted through. Stainless steel and aluminum are the most commonly used metals for spanners to ensure durability even if the item is dropped from high.

- Q: i am getting my industrial (scaffold) pierced on one ear and i want my cartilage on the other ear, how long do i have to wait between them? What are pros and cons for industrial (scaffold)? what are risks and stuff and how much is it? i want to get it so any information or anything i should know would be great thanks especially for industrial:)

- i heard from people after a year an industrial still hurts and they usually have to take them out

- Q: Specification and type of scaffold erection

- 4 the vertical pole of the scaffold, the size of the cross bar according to the specific use of the scaffold to determine the specific circumstances, but shall not exceed the following values:Horizontal vertical rod vertical rod large cross bar small crossbar small cantilever cantilever length 1.5m 1.2m 2.0m 1.5m 0.45M5 ramps board, springboard slope is no larger than 1:3, width of not less than 1.5m. 6 wooden rods: wire with 8#

- Q: Why is it necessary to keep records of all inspection carried out on scaffolds as stated in Regulation 39?

- To cover your A** in case of injury or an inspection.

Send your message to us

Steel Rebar Couplers Made in China with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords